If you’re looking for the 12 best high-end SLS 3D printers of 2025, I’ve got you covered. These models offer impressive build volumes, blazing speeds, and pinpoint precision, making them perfect for professional and industrial applications. They feature advanced features like automatic calibration, high-temperature hotends, and durable construction for long-term reliability. To discover detailed insights about each printer’s strengths and capabilities, keep exploring—there’s plenty more to learn about these top-tier machines.

Key Takeaways

- The list highlights top high-end SLS 3D printers of 2025 with advanced precision and performance features.

- It emphasizes large build volumes, structural stability, and material versatility for complex manufacturing.

- Speed, high-quality laser scanning, and efficient workflow capabilities are key performance factors.

- User-friendly calibration, automation, and maintenance features ensure consistent, high-accuracy results.

- Compatibility with diverse high-temperature powders and advanced hotend technology enhances material options.

QIDI PLUS4 3D Printer with Large Print Size

If you’re looking for a high-end 3D printer that combines large build capacity with professional-level precision, the QIDI PLUS4 is an excellent choice. It boasts a substantial print size of 12x12x11 inches, letting me produce multiple models simultaneously and boost my workflow. Its sturdy build, featuring a high-speed Core XY structure, dual Z-axis motors, and a 6mm aluminum hot bed, ensures high accuracy and durability. The sleek, modern design makes it less bulky than traditional printers, and its quiet operation helps maintain a focused workspace. Overall, the QIDI PLUS4 balances size, precision, and user-friendly features, making it ideal for serious professionals and hobbyists alike.

Best For: Professionals and hobbyists seeking a large-capacity 3D printer with high precision, fast speeds, and versatile material compatibility.

Pros:

- Large print size of 12x12x11 inches allows for multiple models and complex projects simultaneously.

- High-speed Core XY structure supports rapid printing up to 600mm/s with excellent accuracy.

- Enclosed chamber with chamber heating and multi-material support enhances printing stability for engineering-grade filaments.

Cons:

- Slightly heavy and sizable, which may require dedicated space and handling considerations.

- Initial firmware bugs and hardware issues like SSR overheating may need troubleshooting.

- Lack of automatic power recovery after outages and filament storage placement could impact convenience.

ELEGOO Neptune 4 Plus 3D Printer

The ELEGOO Neptune 4 Plus stands out as an excellent choice for hobbyists and small-scale professionals who need high-quality prints with large build volumes. It delivers lightning-fast speeds up to 500mm/s, supported by Klipper firmware, with accelerations up to 12,000mm/s² for rapid, detailed prints. Its sizable build area of 320x320x385mm accommodates bigger projects or multiple objects simultaneously. Equipped with automatic calibration features like input shaping and sensors, it guarantees precision and reduces vibrations. The dual-gear direct drive extruder and high-temperature hotend support various filament types, making it versatile. Overall, it combines speed, size, and ease of use for demanding enthusiasts.

Best For: hobbyists and small-scale professionals seeking a high-speed, large-volume 3D printer capable of detailed, versatile prints with easy calibration and reliable performance.

Pros:

- Fast printing speeds up to 500mm/s supported by Klipper firmware for quick project completion

- Large build volume of 320x320x385mm ideal for bigger models or multiple objects

- Automatic calibration features like input shaping and sensors ensure high precision and reduced vibrations

Cons:

- Setup instructions are not fully detailed, requiring users to research additional resources

- Manual adjustments are still needed for optimal auto bed leveling and calibration

- Software issues such as failed print resumes and WiFi connectivity can affect user experience

Creality Ender 5 Max 3D Printer

Designed for professionals and serious hobbyists who need large-scale, high-speed 3D printing, the Creality Ender 5 Max stands out with its massive 400×400×400mm build volume and rapid print speeds. It features a high-torque XY motor capable of reaching speeds up to 700 mm/s with 2000 mm/s² acceleration, enabling fast production of complex models. The dual-gear direct drive extruder ensures smooth extrusion, clog resistance, and durability. Its reinforced frame and 36-point auto-leveling system guarantee stability and precise layer accuracy. With a fast-heating 1000W bed supporting various filaments and built-in Wi-Fi for remote management, it’s designed for efficient, large-scale printing workflows.

Best For: professionals and serious hobbyists seeking large-scale, high-speed 3D printing with reliable precision and versatile material options.

Pros:

- Massive 400×400×400mm build volume supports large and batch projects.

- High-speed capabilities up to 700 mm/s for rapid model production.

- Durable all-metal dual gear extruder ensures smooth filament feeding and longevity.

Cons:

- Large size may require substantial workspace and setup time.

- High power consumption due to 1000W heated bed.

- Advanced features might require a learning curve for beginners.

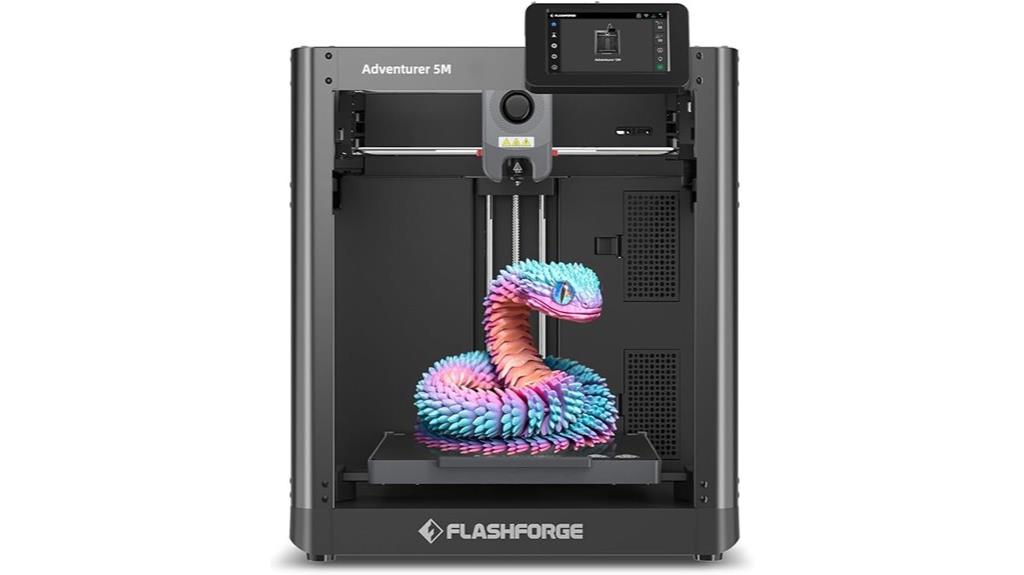

FLASHFORGE Adventurer 5M 3D Printer with Auto Leveling and High-Speed Printing

The FLASHFORGE Adventurer 5M stands out as an excellent choice for hobbyists and small-scale professionals who prioritize high-speed, reliable printing with minimal setup. Its enclosed design, all-metal CoreXY structure, and fully automatic bed leveling make calibration quick and straightforward. Capable of reaching 280°C with a high-flow nozzle, it delivers fast, high-quality prints at speeds up to 600mm/s. The magnetic, self-leveling heated bed simplifies removal and maintenance, while features like quick nozzle changes and vibration compensation ensure consistent results. Overall, the Adventurer 5M combines ease of use, speed, and upgrade potential, making it ideal for prototyping, creative projects, and education.

Best For: hobbyists, educators, and small-scale professionals seeking a reliable, high-speed 3D printer with minimal setup and maintenance.

Pros:

- Fast printing speeds up to 600mm/s with stable high-quality results

- Fully automatic bed leveling and easy filament loading simplify setup and maintenance

- Enclosed design and upgrade options enhance safety, versatility, and print quality

Cons:

- Limited build volume (220x220x220mm) may restrict larger projects

- Included slicer software (FlashPrint) is basic; users often prefer third-party options like Orca-Flashforge

- Some users report filament feeding issues or nozzle clogs over time

Creality Ender 3 V3 SE 3D Printer

Looking for a reliable 3D printer that combines speed, ease of use, and solid build quality? The Creality Ender 3 V3 SE fits the bill perfectly. It offers an 8.66×8.66×9.84-inch build volume with a sturdy frame, dual Z-axis lead screws, and wear-proof steel linear shafts, ensuring high accuracy and stability. Preassembled for quick setup, it’s ideal for both beginners and experienced users. Supporting speeds up to 250mm/s with a powerful Sprite dual-geared extruder, it reduces print times while maintaining quality. Features like auto bed leveling and Wi-Fi connectivity make operation straightforward, making it a versatile, value-packed choice.

Best For: hobbyists, beginners, and experienced users seeking a fast, reliable, and easy-to-assemble 3D printer with high precision and solid build quality.

Pros:

- Quick setup with preassembled design and user-friendly instructions

- High-speed printing up to 250mm/s with excellent print quality

- Auto bed leveling and Wi-Fi connectivity for simplified operation

Cons:

- Occasional hardware issues such as power plug failures or motherboard damage reported by some users

- Limited software compatibility with third-party slicing programs

- Noise levels and minor setup adjustments may be necessary for optimal performance

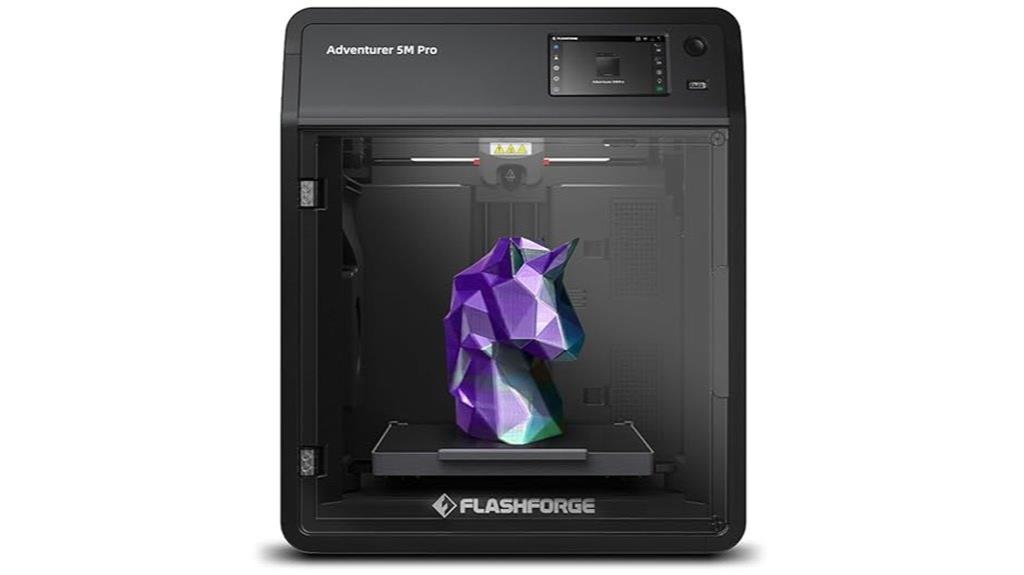

FLASHFORGE Adventurer 5M 3D Printer

If you’re seeking a high-speed 3D printer that combines ease of use with professional-quality results, the FlashForge Adventurer 5M is an excellent choice. This enclosed, CoreXY machine features a 220x220x220mm build volume, fully automatic bed leveling, and a direct extruder capable of reaching 280°C. Its high-flow nozzle and rapid 35-second warm-up enable fast, stable printing at speeds up to 600mm/s. The magnetic, self-leveling heated bed simplifies removal and maintenance. Designed for quick setup and consistent quality, it’s perfect for rapid prototyping and creative projects, offering a balance of speed, reliability, and upgrade potential.

Best For: hobbyists, educators, and small-scale prototyping enthusiasts seeking a reliable, high-speed 3D printer with easy setup and professional-quality results.

Pros:

- Fast printing speeds up to 600mm/s with stable high-quality output

- Fully automatic bed leveling and magnetic self-leveling heated bed for easy maintenance

- User-friendly touchscreen interface and straightforward setup suitable for beginners and experienced users alike

Cons:

- Limited build volume of 220x220x220mm may restrict larger projects

- Included slicer software (FlashPrint) is basic; better control requires switching to third-party options like Orca-Flashforge

- Some users report filament feeding issues or nozzle clogs requiring troubleshooting

FLASHFORGE AD5M Pro 3D Printer with High-Speed & Precision

Designed for professionals and serious hobbyists who demand both speed and precision, the FlashForge AD5M Pro stands out with its high-speed printing capabilities reaching up to 600mm/s. Its fully enclosed, compact design guarantees safety and quiet operation, making it suitable for home or classroom use. Setup is straightforward, with an intuitive touchscreen interface and automatic bed leveling that guarantees perfect first layers. The printer supports a wide range of filaments, including TPU, ABS, and PETG, thanks to its high-temp extruder and quick-detachable nozzles. Rapid heating, consistent quality, and minimal calibration make the AD5M Pro a reliable choice for high-performance, high-speed 3D printing.

Best For: professionals, educators, and serious hobbyists seeking high-speed, precise 3D printing with versatile material support in a safe and user-friendly enclosed environment.

Pros:

- High-speed printing up to 600mm/s with consistent quality

- Fully enclosed design with effective filtration for safe indoor use

- Automatic bed leveling and easy setup enhance user experience

Cons:

- Some users experience difficulties connecting monitor cables due to non-standard sockets

- Software compatibility issues on newer macOS platforms may require troubleshooting

- Noise levels from fans and airflow turbulence can be disruptive during operation

Creality 3D Printer K1 SE Fully Assembled

The Creality 3D Printer K1 SE Fully Assembled stands out for beginners and kids thanks to its effortless setup and user-friendly features. It arrives fully assembled and pre-tuned, allowing you to get started within three minutes—just plug it in and go. Its auto-calibration feature removes the hassle of manual leveling, making it perfect for newcomers. With a Core XY structure, it offers blazing speeds up to 600mm/s and high precision, thanks to stable enclosed printing. The durable tri-metal nozzle heats quickly, supporting various filaments. Plus, its quiet operation, vibration damping, and reliable support make it an excellent choice for those new to 3D printing.

Best For: beginners, kids, and those seeking an easy-to-use, fully assembled 3D printer for fast, precise, and reliable printing.

Pros:

- Fully assembled and pre-tuned, enabling setup within three minutes.

- Auto-calibration removes manual leveling, simplifying operation for newcomers.

- High-speed printing up to 600mm/s with stable, enclosed build space for high accuracy.

Cons:

- May be less customizable for advanced users seeking extensive manual controls.

- The enclosed design could limit ventilation or access during certain modifications.

- Higher initial cost compared to entry-level, DIY 3D printers.

Longer LK5 Pro 3D Printer with Large Printing Size

For those seeking to produce large, detailed 3D models efficiently, the Longer LK5 Pro stands out with its impressive 11.8 by 11.8 by 15.7-inch build volume. Its reinforced inclined rods form a stable triangular structure, reducing vibration and wobble during high-speed printing. The delta-style frame ensures consistent stability, enabling detailed, long-duration prints without layer shifts. Equipped with automatic X and Y-axis calibration, it achieves up to 0.1mm accuracy. The silicon carbide lattice glass platform ensures uniform temperature and strong adhesion, while features like filament detection, auto-resume, and high-speed capabilities make it ideal for both hobbyists and professionals seeking precision and versatility.

Best For: hobbyists, educators, and professionals seeking large-scale, high-precision 3D printing with reliable stability and speed.

Pros:

- Large build volume (11.8 x 11.8 x 15.7 inches) suitable for big projects

- Stable triangular frame design minimizes vibrations and wobble during high-speed printing

- Automatic X and Y-axis calibration ensures high accuracy up to 0.1mm

Cons:

- Fully assembled components still require some setup and calibration for optimal performance

- Larger size may require more workspace and storage considerations

- Open-source firmware may require some technical knowledge for advanced customization

Longer LK5 Pro 3D Printer with Large Printing Size

If you’re looking to produce large, detailed models without sacrificing speed or precision, the Longer LK5 Pro 3D Printer stands out as an excellent choice. Its reinforced inclined rods create a stable triangular structure, reducing vibration during high-speed printing. With a substantial build volume of 11.8 x 11.8 x 15.7 inches, it offers plenty of space for bigger projects. The printer achieves up to 0.1mm accuracy thanks to automatic calibration, a silicon carbide lattice glass platform, and upgraded extruder components. Capable of printing at 180mm/s, it balances speed with quality, making it ideal for both industrial and hobbyist applications.

Best For: hobbyists, educators, and professionals seeking large-scale, high-precision 3D printing with fast turnaround times.

Pros:

- Large build volume (11.8 x 11.8 x 15.7 inches) for bigger projects

- High printing speed up to 180mm/s with precise layer quality

- Automatic calibration and open-source firmware for easy customization

Cons:

- Approximately 95% pre-assembled, which may require additional setup time

- Potential for vibration if not properly stabilized despite reinforced frame

- Open-source firmware may require technical familiarity for advanced modifications

Official Creality Ender 3 3D Printer

Designed for beginners and students, the Creality Ender 3 3D Printer offers an accessible entry point into 3D printing with its DIY assembly and user-friendly features. It has a build volume of 8.66×8.66×9.84 inches, making it suitable for various projects. The printer includes a resume printing function, so it can recover from power outages, and supports printing via SD card or computer connection. Its upgraded extruder minimizes plugging issues, while the V-shape with POM wheels ensures smooth, quiet, and durable movements. Minimal assembly (about two hours) and safety testing make it ideal for education and hobbyists alike.

Best For: beginners, students, and hobbyists looking for an easy-to-assemble 3D printer with reliable features and educational value.

Pros:

- User-friendly DIY assembly suitable for beginners and educational settings

- Resume printing function to recover from power outages

- Upgraded extruder reduces plugging and extrusion issues

Cons:

- Does not support phone connectivity for printing control

- Limited build volume for larger projects

- Requires manual verification of power supply voltage to prevent shutdowns

Fully Assembled Mini 3D Printer for Kids and Beginners

The Fully Assembled Mini 3D Printer stands out as an ideal choice for kids and beginners who want a hassle-free, ready-to-use 3D printing experience. Its compact size and lightweight design make it perfect for home, classroom, or dorm use. The pre-assembled unit requires minimal setup—just connect the filament, insert the SD card, and power on. Features like auto-leveling, a magnetic build plate, and an intuitive LCD screen simplify operation. Supporting WiFi and major slicing software, it produces high-quality, detailed prints with ease. This user-friendly printer offers a fun, reliable introduction to 3D printing, making it perfect for newcomers and young creators alike.

Best For: beginners, kids, and families seeking an easy-to-use, reliable 3D printer for educational and creative projects at home or in the classroom.

Pros:

- User-friendly with minimal assembly and straightforward operation

- Compact, lightweight design ideal for small spaces and portability

- Supports multiple platforms and slicing software for versatile use

Cons:

- Small build volume limits larger project sizes

- Requires occasional bed cleaning and filament management

- Limited to 1.75mm PLA and compatible filaments, reducing material variety

Factors to Consider When Choosing High‑End SLS 3D Printers

When selecting a high-end SLS 3D printer, I focus on key factors like resolution and accuracy to guarantee precise prints. I also consider build volume size and material compatibility to match my project needs, along with printing speed to improve efficiency. Finally, I keep an eye on cost and budget to find a machine that offers the best value for my investment.

Resolution and Accuracy

Choosing a high-end SLS 3D printer hinges considerably on resolution and accuracy, as these factors determine the detail, surface quality, and dimensional fidelity of your prints. Higher resolution, with layer heights as low as 20-50 microns, allows for finer details and smoother surfaces, making intricate features possible. Accuracy depends on precise laser or projector calibration, typically within ±50 microns, ensuring parts match exact specifications even in complex geometries. Achieving ideal resolution requires high-quality laser spot sizes and stable powder bed conditions, reducing layering errors and surface imperfections. Consistent accuracy and resolution are maintained through advanced controls like real-time monitoring, environmental stabilization, and precise powder handling systems. These elements are essential for producing detailed, high-quality parts consistently in high-end SLS printing.

Build Volume Size

Build volume size plays a key role in determining the capabilities of high-end SLS 3D printers. Larger build volumes allow me to produce bigger parts or multiple items in a single print, boosting efficiency. Typically, these printers have build volumes ranging from about 200 x 200 x 150 mm to over 300 x 300 x 400 mm, fitting various complex and large-scale designs. A bigger build volume offers more design flexibility, letting me create intricate, multi-component assemblies without splitting models. However, increasing the size often means more advanced laser or sintering systems, which can add to the printer’s size, cost, and complexity. When choosing, I weigh the desired build volume against resolution and accuracy to ensure quality isn’t compromised at larger sizes.

Material Compatibility

Material compatibility is a crucial factor I consider to guarantee my high-end SLS 3D printer meets diverse project needs. These printers support a wide range of powders like nylon, TPU, ABS, and composites, allowing for versatile applications. For specialized or custom powders, I check if firmware adjustments or specific system configurations are needed to ensure proper flow and sintering. High-end models often handle high-temperature powders such as PEEK or PEI, which require precise temperature control and suitable chamber conditions. Compatibility depends on the printer’s hotend and chamber temperature ranges, typically exceeding 300°C for broad material options. Confirming that the printer works with proprietary or third-party powders gives me the flexibility to experiment and optimize for different materials and project requirements.

Printing Speed Capabilities

Speed is a critical factor when selecting a high-end SLS 3D printer, as it directly affects production efficiency and turnaround times. These printers typically support speeds of 10 to 20 grams per hour, enabling the quick production of complex parts. Advanced models can achieve layer exposure times as low as 0.02 seconds, markedly reducing print durations for large or detailed objects. Laser scanning speed, often reaching hundreds of millimeters per second, plays a key role in build efficiency. However, maintaining quality at high speeds requires robust cooling and precise motion control. It’s essential to balance speed with resolution and surface finish because increasing velocity can compromise accuracy if not properly managed. Prioritizing these speed capabilities ensures maximum productivity without sacrificing part quality.

Cost and Budget

Choosing a high-end SLS 3D printer involves more than just considering its features and capabilities; understanding the costs involved is vital for making a smart investment. These printers typically range from $50,000 to over $500,000, so careful budget planning is essential. You need to account for the initial purchase, but also for post-processing equipment and materials, which can considerably raise total expenses. Budget constraints might limit access to advanced features like larger build volumes or higher resolution. Operating costs, including powder materials, maintenance, and spare parts, can add up to thousands annually. Evaluating the total cost of ownership helps guarantee the printer fits both your current needs and long-term financial plans, avoiding surprises down the line.

Software and User Interface

Have you ever struggled with complex controls or confusing interfaces on high-end SLS 3D printers? If so, you’re not alone. The best models feature intuitive user interfaces, often with a color touchscreen that makes navigation straightforward. Advanced software compatibility is vital, supporting popular slicing programs and proprietary tools to optimize print settings. Real-time monitoring, remote control, and data management streamline workflows and speed up troubleshooting. Automated features like auto bed leveling, filament detection, and process calibration help reduce user errors and ensure consistent quality. Additionally, open-source or customizable firmware can be a game-changer for experienced users, allowing fine-tuning for specific applications. A well-designed interface and smart software integration are essential for maximizing the printer’s performance and minimizing hassle during complex projects.

Maintenance and Support

Ever wondered what keeps a high-end SLS 3D printer running smoothly over time? Regular maintenance is essential, especially for laser optics, recoaters, and powder handling systems, to guarantee consistent print quality. Having reliable technical support and readily available spare parts minimizes downtime during complex jobs or troubleshooting. Routine calibration of the laser, build chamber temperature, and recoating mechanism helps maintain dimensional accuracy and surface finish, which are indispensable for precision parts. Proper training and detailed user manuals are invaluable, particularly for advanced features like powder recycling and chamber purging. Additionally, vendor responsiveness and extensive customer support services are crucial for swift issue resolution, protecting your investment. Choosing a system with strong support ensures your high-end printer remains reliable and performs at peak levels over time.

Reliability and Durability

When selecting a high-end SLS 3D printer, reliability and durability become critical factors that directly impact your investment’s longevity and performance. These printers rely on robust components like reinforced linear rails and high-quality laser sources to guarantee consistent operation over time. Materials such as metal frameworks and sealed chambers considerably enhance reliability, especially during continuous production. Precise calibration and proper component alignment are essential to maintain high print quality across extended runs. Advanced thermal management systems prevent overheating and reduce wear on key parts like lasers and fans, extending their lifespan. Regular maintenance, including cleaning and part replacements, is crucial to sustain dependable performance. Prioritizing these factors ensures your printer remains reliable, delivers consistent results, and maximizes your return on investment.

Frequently Asked Questions

What Are the Maintenance Requirements for High-End SLS 3D Printers?

Maintenance for high-end SLS 3D printers involves regular cleaning of the build chamber and recoating the powder bed to guarantee best print quality. I also check and replace filters, lubricate moving parts, and calibrate the system periodically. Keeping the laser optics spotless and monitoring the temperature settings helps prevent issues. Consistent maintenance like this keeps my printer running smoothly and ensures top-tier precision and performance.

How Does Powder Recycling Impact Print Quality and Cost?

Powder recycling can substantially impact print quality and cost. When I reuse powder, I notice slight degradation in surface finish and accuracy if not properly managed. To maintain high quality, I carefully sieve and blend recycled powder with fresh material. This approach helps control costs by reducing waste, but I stay vigilant because excessive recycling can compromise part strength and precision. Proper process controls are essential for ideal results.

What Safety Features Are Essential for High-End SLS 3D Printers?

Safety features are essential for high-end SLS 3D printers. I always look for enclosed chambers to contain dust and fumes, which keeps the workspace safe. Automatic shutdown systems are critical, especially if overheating or malfunctions occur. Proper ventilation, fire suppression systems, and safety interlocks ensure the machine doesn’t operate if doors are open. These features protect users and improve overall reliability, making high-end printing safer and more efficient.

Can These Printers Handle Multi-Material or Multi-Color SLS Printing?

Think of these printers as symphony conductors—some can handle multiple materials or colors, orchestrating complex, vibrant creations. Many high-end SLS printers in 2025 do support multi-material or multi-color printing, though options vary. Advanced models use specialized software and hardware to blend powders seamlessly, allowing for intricate, multi-faceted designs. If you want true multi-material capabilities, I recommend checking the specifications carefully to find the perfect match for your creative needs.

What Is the Typical Lifespan and Durability of High-End SLS 3D Printers?

High-end SLS 3D printers typically last around 5 to 10 years with proper maintenance. I’ve found that their durability depends on usage frequency, calibration, and how well I care for the components. Regularly replacing worn parts, cleaning the build chamber, and following manufacturer guidelines help extend their lifespan. While they’re built for long-term use, keeping up with maintenance is key to ensuring consistent precision and performance over time.

Conclusion

If you’re seeking precision, performance, and top-tier quality, these high-end SLS 3D printers are your best bet. They deliver speed, size, and accuracy, transforming your ideas into reality. Whether it’s large builds, detailed models, or fast production, these printers handle it all. So, choose wisely, focus on your needs, and elevate your 3D printing game. Because with the right machine, the possibilities are endless, and your creations will truly stand out.