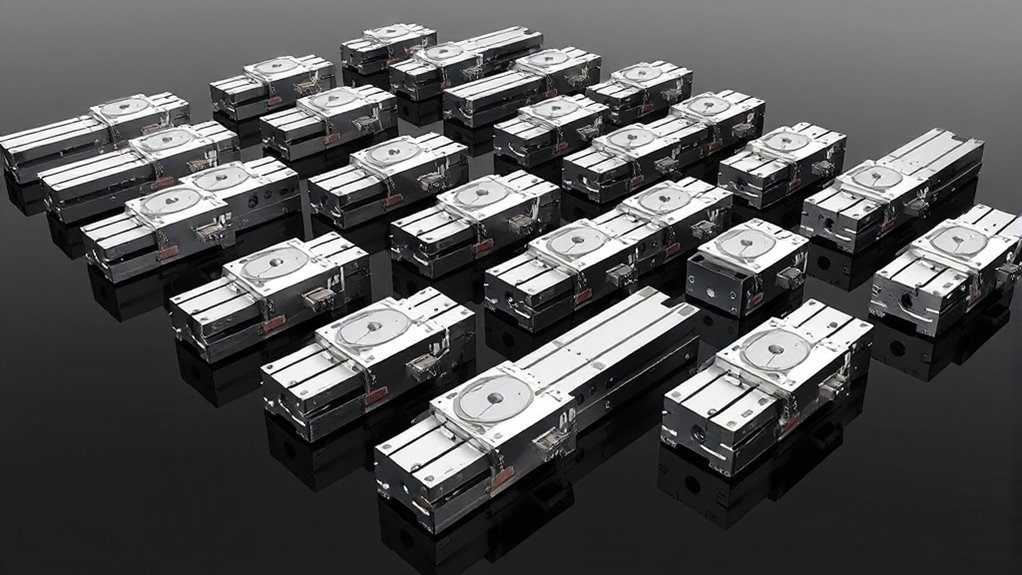

When selecting the 15 best linear translation stages for precision and smooth movement, I focus on quality construction, accurate micrometer adjustments, and reliable guide mechanisms like cross roller bearings. These stages are made from durable materials like anodized aluminum, supporting fine displacement with minimal backlash. They work well in optical, industrial, and testing applications, offering stability and versatility. Keep exploring, and you’ll discover detailed options suited for your specific needs.

Key Takeaways

- Look for stages with high-precision micrometer heads offering resolutions of 0.01mm or better for accurate positioning.

- Choose models equipped with cross roller bearings to ensure backlash-free, smooth linear motion.

- Opt for durable materials like anodized aluminum alloys for long-term wear resistance and stability.

- Consider stages with modular designs supporting multi-axis configurations for versatile applications.

- Verify load capacities and travel ranges align with your specific measurement or testing requirements.

SEMX60-AC Linear Stage 60x60mm Micrometer Manual Translation Stage

If you’re looking for a reliable manual translation stage for precise positioning, the SEMX60-AC is an excellent choice. This 60x60mm stage features micrometer adjustment, making fine displacement tuning straightforward. Its durable aluminum alloy construction with a black anodized surface assures wear resistance and a sleek look. The single X-axis sliding track provides stability and smooth movement, ideal for optical measurements, testing, and production machinery. Machined with high precision, it guarantees accurate and stable operation. Backed by Keenso’s professional support, this well-made stage offers reliable performance and exceeds expectations, making it perfect for applications requiring precise and controlled linear motion.

Best For: researchers, optical technicians, and production engineers needing precise manual linear positioning for measurements, testing, or machinery setup.

Pros:

- Durable aluminum alloy construction with a sleek black anodized finish for wear resistance and aesthetics

- Precise micrometer adjustment allows for fine and controlled displacement tuning

- Stable and smooth movement thanks to the single X-axis sliding track, ideal for optical and industrial applications

Cons:

- Manual operation may not be suitable for high-speed or automated systems

- Limited to linear motion along a single axis, restricting multi-directional positioning

- Size (60x60mm) may be inadequate for applications requiring larger travel ranges

X Axis Manual Precision Linear Stage 80x80mm

The X Axis Manual Precision Linear Stage 80x80mm is an ideal choice for professionals seeking accurate and smooth linear movement in their precision applications. Crafted from durable aluminum alloy with a black anodized surface, it offers excellent longevity and corrosion resistance. Its design features a single X-axis linear guide sliding track and an 80×80mm table, with overall dimensions of approximately 165×92×24.5mm. Precision-machined for stability, it guarantees precise and consistent movement. The inclusion of a micrometer fine-tuning mechanism allows for fine displacement adjustments, making it perfect for optical experiments, testing, or applications requiring meticulous positioning.

Best For: professionals and researchers requiring precise, smooth linear positioning for optical experiments, testing, and fine-tuning applications.

Pros:

- Made of durable aluminum alloy with corrosion-resistant black anodized finish for long-lasting use

- Features micrometer fine-tuning for highly accurate displacement adjustments

- Compact design with stable, precision-machined components suitable for delicate tasks

Cons:

- Limited to single-axis movement, not suitable for multi-axis applications

- Overall size may be restrictive for large or complex setups

- Manual operation may not meet the needs of automated or high-speed applications

Linear Translation Stage XYZ Axis Adjustable 40x90mm

Looking for a versatile linear translation stage that adapts to various setups? The XYZ Axis Adjustable 40x90mm stage is perfect for a wide range of industries, including optical, semiconductor, and microscopy. It’s easy to install on side bases, columns, or inclined bases, allowing horizontal, vertical, or inclined configurations. Smooth, stable movement is controlled via a gear handle and dovetail mechanism, with safety features like the R angle for secure handling. Made from lightweight yet durable aluminum alloy, it offers precise micropositioning without play. Users praise its solid build and ease of use, making it a reliable choice for demanding applications.

Best For: researchers, engineers, and technicians seeking precise, adaptable linear positioning solutions across optical, semiconductor, microscopy, and manufacturing applications.

Pros:

- Easy to install on various bases and configurations, supporting horizontal, vertical, or inclined setups

- Smooth, stable movement with gear handle and dovetail mechanism for precise control

- Made from lightweight yet durable aluminum alloy, ensuring reliable performance and ease of handling

Cons:

- Limited movement range of 40x90mm may not suit very large or complex setups

- Mechanical components may require periodic maintenance to maintain optimal smoothness

- Deep hole processing requires additional graded feed mechanism, adding complexity for certain tasks

Linear Translation Stage, Manual X Linear Stage

Manual X linear translation stages are ideal for users requiring precise, reliable positioning without the complexity of motorized systems. I find the SEMCIC-80 X rack pinion sliding table perfect for tasks like inspection, optical experiments, and fine displacement tuning. Its compact, portable design makes it easy to use in various settings. The high-precision gear system provides accurate 30μm movement with just a 0.7-inch knob turn, ensuring consistent results. Made from durable black oxidized aluminum alloy, it withstands wear and environmental factors. With a 1.2×2 inch size, six mounting holes, and load capacities supporting moderate weights, it offers stable, long-term performance.

Best For: users needing precise, reliable manual positioning for inspection, optical experiments, or fine displacement tuning in compact and portable setups.

Pros:

- High-precision 30μm movement with minimal knob rotation for accurate positioning

- Durable construction from black oxidized aluminum alloy resistant to wear and environmental factors

- Compact size with secure mounting options supports stable long-term operation

Cons:

- Limited load capacity may not suit very heavy or high-force applications

- Manual operation may be less suitable for automated or high-speed positioning needs

- Slightly limited stroke range of ±1.2 inches might restrict certain large-range applications

Linear Translation Stage, XYZ Manual Trimming 40 x 90mm HF3A90

If you need a reliable, high-precision linear translation stage for delicate positioning tasks, the HF3A90 model stands out. Its compact size of 40 x 90mm and ±40mm stroke make it ideal for optical, measurement, and semiconductor applications. Made from lightweight, durable black anodized aluminum, it features a dovetail rail for smooth, stable movement and a gear-driven rack mechanism controlled manually with rotating knobs. The stage supports 3-axis XYZ movement with minimum 0.01mm scale accuracy and a load capacity of up to 98N. Its detachable structure and threaded holes simplify mounting and maintenance, ensuring precise, controlled positioning in demanding environments.

Best For: professionals and researchers needing precise, reliable linear positioning in optical, measurement, semiconductor, or testing applications.

Pros:

- High-precision movement with a minimum scale of 0.01mm and parallelism within 0.1mm

- Durable, lightweight black anodized aluminum construction for easy handling and longevity

- Versatile mounting options with 10 threaded holes and detachable structure for maintenance

Cons:

- Manual operation may be less suitable for automated or high-speed applications

- Limited size options may restrict use in larger systems or specific setups

- Requires careful calibration to maintain maximum accuracy over time

Linear Translation Stage XYZ Axis, Adjustable 40 x 90mm HF3‑A90

The Linear Translation Stage XYZ Axis, Adjustable 40 x 90mm HF3‑A90 stands out as an ideal choice for users requiring precise manual positioning in optical, measurement, or industrial applications. Made from lightweight, durable black anodized aluminum, it offers smooth, anti-friction movement thanks to dovetail rails and gear-driven tracks. Its adjustable trimming allows fine-tuning, with a minimum resolution of 0.01mm and a parallelism accuracy of 0.1mm over 60mm. Capable of handling up to 98N, it features a detachable structure for easy maintenance and versatile mounting options with ten threaded holes. This stage ensures stable, accurate linear motion across various technical tasks.

Best For: precision engineers, optical system developers, and industrial technicians needing accurate manual positioning in scientific and manufacturing setups.

Pros:

- Lightweight and durable due to black anodized aluminum construction

- Smooth, anti-friction movement with dovetail rails and gear-driven tracks

- Fine adjustment with a high resolution of 0.01mm and versatile mounting options

Cons:

- Manual operation may be less suitable for automated or high-speed applications

- Limited to a maximum load capacity of 98N (10kgf), which may not suit very heavy setups

- Fixed size options may not accommodate larger or more specialized systems

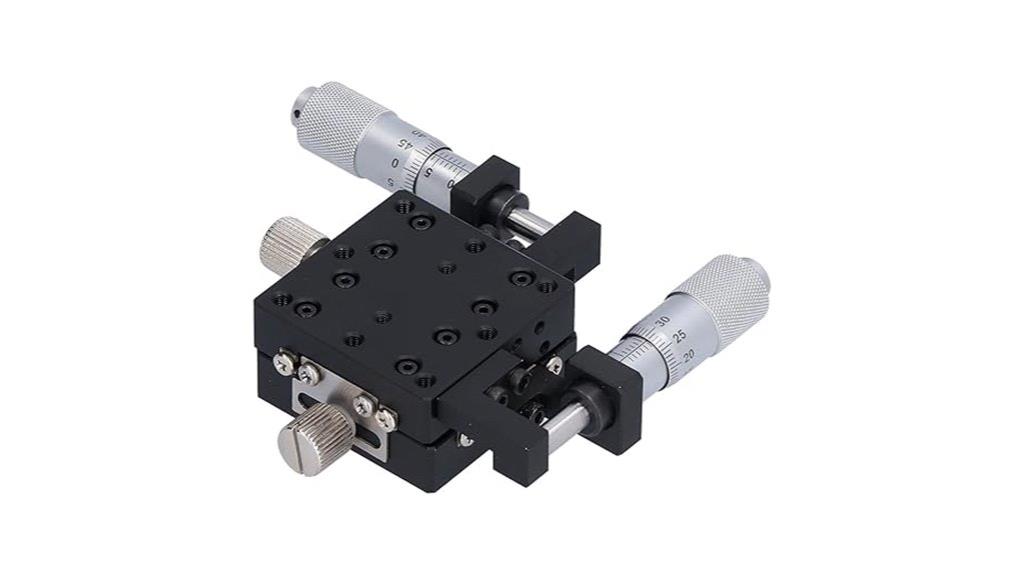

XY Linear Stage, M2WG-A40 Linear Translation Stage with Micrometer

For those seeking precise and versatile positioning in optical measurement and machining, the XY Linear Stage, M2WG-A40 with Micrometer stands out as an ideal choice. Its lightweight aluminum alloy construction with a black anodized finish assures durability, corrosion resistance, and an attractive appearance. The dual-layer structure provides about 22mm of thickness, with deburred edges for safety. It offers ±5mm stroke in both directions, driven by a micrometer knob for accurate adjustments. The cross roller track guarantees smooth movement, with a straightening accuracy of 0.03mm. Eight mounting holes add versatility, making it perfect for applications like microscopy, semiconductor processing, and precision machining.

Best For: precision engineers, optical measurement professionals, and machining specialists requiring high-accuracy manual positioning tools.

Pros:

- Lightweight yet durable aluminum alloy construction with corrosion and scratch resistance.

- High-precision movement with ±5mm stroke and 0.03mm straightening accuracy.

- Versatile mounting options with eight threaded holes suitable for various applications.

Cons:

- Manual operation may limit speed compared to motorized stages.

- Limited stroke length of ±5mm, which may require multiple adjustments for larger movements.

- Requires careful handling to maintain calibration and precision over time.

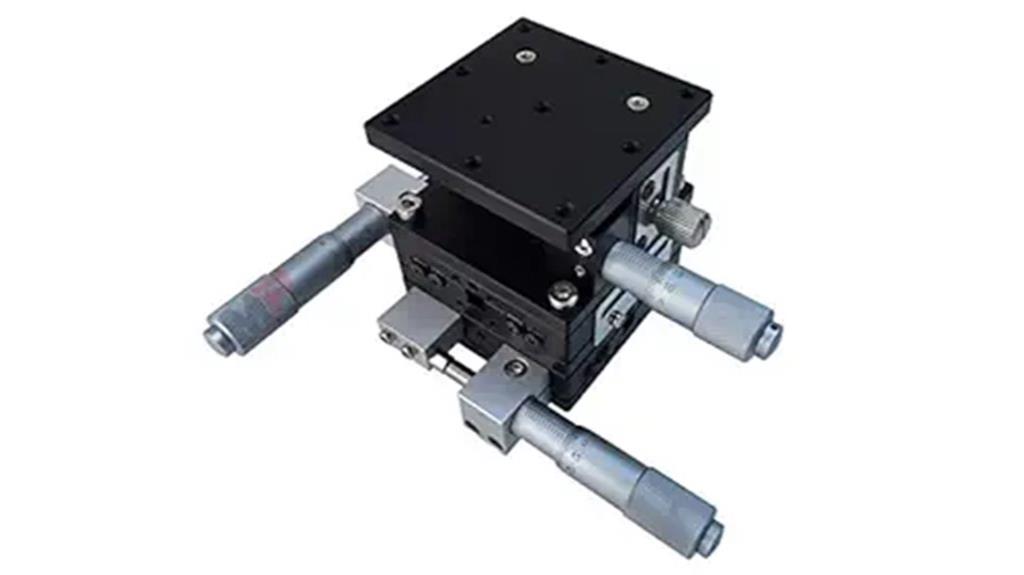

XYZ Linear Translation Stage, T60XYZ-25L10A Precision 3-Axis Positioning System

The XYZ Linear Translation Stage, T60XYZ-25L10A, stands out as an ideal choice for those needing precise multi-axis positioning in a compact setup. It offers 25 mm of travel in the X and Y axes and 10 mm in the Z axis, making it versatile for intricate applications. Equipped with micrometer heads, it guarantees fine adjustment control, while the cross roller bearing assures smooth, accurate linear motion. With a maximum load capacity of 3 kg at the center, it’s suitable for delicate instruments. Plus, it can be integrated into a 4-axis system and works seamlessly with compatible rotation stages R60A-L or R60B-L, enhancing flexibility.

Best For: researchers and engineers requiring precise multi-axis positioning for delicate instrumentation and compact experimental setups.

Pros:

- High precision with micrometer heads for fine adjustments

- Smooth, accurate motion thanks to cross roller bearing

- Compact design with versatile 3-axis travel for detailed applications

Cons:

- Limited load capacity of 3 kg may restrict heavier equipment

- Travel ranges are relatively short, which may not suit larger movements

- Compatibility requires additional rotation stages for full 4-axis integration

30 x 50mm Sliding Stage for Fine Tuning and Trimming

A 30 x 50mm sliding stage stands out as an excellent choice for applications demanding precise fine-tuning and trimming, thanks to its high displacement accuracy and smooth manual operation. Made from durable aluminum alloy with a black oxidation finish, it offers wear resistance and long-term reliability. Its large stroke and stable design support high load capacities, ensuring consistent performance during delicate adjustments. Ideal for production machinery, optical measurement, and testing setups, this stage provides accurate, steady movement. Its precise machining and lightweight construction make it easy to operate while maintaining stability, making it a trusted tool for meticulous fine-tuning and trimming tasks.

Best For: professionals and technicians requiring precise fine-tuning, trimming, or adjustment in production, optical measurement, or testing environments.

Pros:

- High displacement accuracy ensures precise adjustments.

- Durable aluminum alloy construction with wear-resistant black oxidation finish for longevity.

- Large stroke and high load capacity support stable performance during delicate operations.

Cons:

- May be less suitable for applications requiring extremely rapid or automated movements.

- Manual operation might be less efficient for high-volume or repetitive tasks.

- Limited to dimensions of 30 x 50mm, which may not suit larger-scale applications.

Walfront Linear Translation Stage with Adjustable XYZ Axis

If you need precise and smooth linear movement across multiple axes, the Walfront Linear Translation Stage with Adjustable XYZ Axis is an excellent choice. Its lightweight black anodized aluminum alloy body ensures durability and anti-friction performance, making it ideal for delicate applications. Supporting three axes—X, Y, and Z—it features gear-driven manual rotation handles for stable, precise adjustments. The gear and rack drive mechanisms provide accurate control, while R angle safety features make handling safe and straightforward. Suitable for optical, semiconductor, microscopy, and manufacturing uses, this stage offers reliable, smooth motion without batteries, ensuring consistent performance in demanding environments.

Best For: professionals and researchers needing precise, multi-axis linear movement in optical, semiconductor, microscopy, and manufacturing applications.

Pros:

- Lightweight and durable black anodized aluminum alloy body for easy handling and longevity

- Supports three axes with gear-driven manual controls for smooth, precise adjustments

- No batteries required, ensuring reliable, maintenance-free operation in demanding environments

Cons:

- Limited to manual operation without motorized or automated features

- Threaded mounting holes are approximately 4mm in diameter, which may require specific fittings

- Size (approx. 40 x 90mm) may be restrictive for very large or complex setups

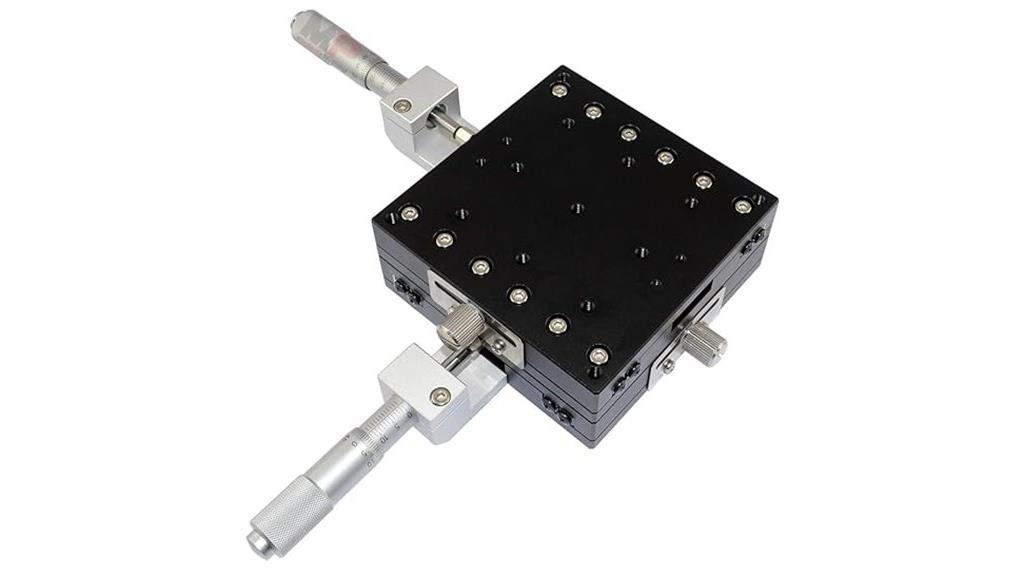

Manual XY Stage with 25mm Travel and 90x90mm Platform

For researchers and technicians needing precise, reliable positioning in compact spaces, the Manual XY Stage with 25mm travel and a 90x90mm platform offers an excellent solution. Its crossed-roller bearing guides guarantee smooth, accurate linear motion throughout the entire range, while the centrally mounted micrometer heads allow fine adjustments with 0.01 mm resolution. Capable of supporting loads up to 10 kg, it’s suitable for a variety of laboratory or industrial tasks. The stage can be easily integrated into XY, XZ, or XYZ configurations using optional accessories like right-angle brackets or vertical translation stages, providing flexible, multi-axis positioning options.

Best For: researchers and technicians requiring precise, reliable positioning in compact laboratory or industrial spaces.

Pros:

- Provides accurate linear motion with 0.01 mm resolution thanks to centrally mounted micrometer heads.

- Supports moderate loads up to 10 kg, suitable for various applications.

- Flexible configuration options allow easy integration into XY, XZ, or XYZ setups using optional accessories.

Cons:

- Limited to a 25 mm travel range, which may not suit applications needing larger movement.

- Manual operation may be less efficient for high-precision or high-speed tasks compared to motorized stages.

- The compact size may restrict use with larger or heavier payloads beyond the specified capacity.

SEMZL60-ACR Z Linear Stage, 60x60mm

The SEMZL60-ACR Z Linear Stage stands out with its compact 60x60mm size and precise Z-axis movement, making it ideal for applications that demand fine vertical positioning. Its single Z linear sliding track ensures smooth, backlash-free motion, perfect for high-accuracy tasks. Made from durable aluminium alloy with a black anodized surface, it offers excellent wear resistance and corrosion protection. The high-quality trimming bearing sliding table guarantees stable performance without play. This stage is well-suited for optical, measurement, and testing applications where precise, reliable vertical translation is critical. Its compact design and precision make it an excellent choice for demanding positioning needs.

Best For: professionals and researchers requiring precise vertical positioning and fine movement control in optical, measurement, and testing setups.

Pros:

- Compact 60x60mm size ideal for space-constrained applications

- Smooth, backlash-free motion with high stability and no play

- Durable construction from high-strength aluminium alloy with corrosion-resistant black anodized finish

Cons:

- Limited to Z-axis movement only, not suitable for multi-axis applications

- May require precise installation and calibration for optimal performance

- Designed primarily for fine adjustments, potentially less suitable for heavy-duty or high-load tasks

Linear Translation Stage with 25mm Travel and 90x90mm Platform

The Linear Translation Stage with 25mm travel and a 90x90mm platform is an excellent choice for users needing precise, reliable positioning in compact spaces. Its cross roller bearing guides guarantee smooth, accurate linear motion throughout the entire travel range. The stage can support loads up to 10 kg, making it suitable for various applications. The center-mounted micrometer head with 0.01 mm resolution allows for fine adjustments, while the modular design enables configurations in XY, XZ, or XYZ orientations. Additionally, the included right-angle bracket offers versatile setup options, ensuring stability and flexibility for demanding positioning tasks.

Best For: users needing precise, reliable linear positioning in compact spaces for laboratory, optical, or automation applications.

Pros:

- Provides smooth, accurate motion thanks to cross roller bearing guides.

- Supports loads up to 10 kg, suitable for various equipment.

- Modular design allows flexible configuration in XY, XZ, or XYZ orientations.

Cons:

- Limited to a 25 mm travel range, which may not suit very large movements.

- Requires careful calibration for optimal precision at high-resolution adjustments.

- Might be more expensive compared to simpler linear stages without bearing guides.

X T60X-13L Precision Linear Translation Stage with 13 mm Travel

If you’re seeking a precise and versatile linear translation stage, the X T60X-13L stands out with its 13 mm travel and 60 x 60 mm platform. It features a crossed-roller bearing guide that ensures stable, accurate motion throughout the entire range. The micrometer head offers 0.01 mm resolution, making fine adjustments straightforward. Its modular design allows for multiple configurations—XY, XZ, or XYZ—using the right angle bracket. Supporting loads up to 5 kg, it’s ideal for applications demanding high accuracy and flexible setup options. Orders are shipped quickly via DHL Express, typically arriving within 3-5 days.

Best For: professionals and researchers requiring precise, flexible linear positioning solutions for optical, mechanical, or electronic applications.

Pros:

- High accuracy with 0.01 mm resolution micrometer head

- Supports multiple configuration orientations (XY, XZ, XYZ) via modular design

- Capable of handling loads up to 5 kg for demanding applications

Cons:

- Limited to 13 mm travel, which may not suit very long-range positioning needs

- Requires careful alignment for optimal performance in complex setups

- Shipping via DHL Express may involve additional costs or delays outside standard delivery times

Milageto x Axis Manual Precision Linear Stage

For those seeking high-precision manual linear stages, the Milageto X Axis Manual Precision Linear Stage stands out with its impressive 0.01mm scale resolution. Its compact size of 6cm x 4cm x 3cm makes it ideal for tight spaces, while the aluminum alloy construction ensures durability without adding unnecessary weight. The 40mm displacement stroke allows precise adjustments, and the helical brass rack sliding mechanism guarantees smooth, stable movement under medium to heavy loads. Perfect for machinery inspection and measurement tasks, this stage provides reliable, fine positioning. Plus, it includes a dovetail groove displacement platform for versatile setup options.

Best For: those needing high-precision manual linear stages for machinery inspection, measurement, and industrial applications involving medium to heavy loads.

Pros:

- High scale resolution of 0.01mm for precise positioning

- Compact size suitable for tight spaces and integration

- Durable aluminum alloy construction ensures strength and lightweight handling

Cons:

- Manual operation may be less efficient for rapid or automated adjustments

- Slight measurement errors (1-2cm) possible due to manual measurement

- Limited displacement stroke of 40mm, which may not suit larger movement requirements

Factors to Consider When Choosing Linear Translation Stages

When selecting a linear translation stage, I focus on key factors like precision and accuracy to meet my application needs. I also consider load capacity and travel range to guarantee the stage can handle the workload and movement requirements. Additionally, material durability and mounting compatibility play vital roles in guaranteeing long-term performance and easy integration.

Precision and Accuracy

Choosing a linear translation stage requires careful consideration of its precision and accuracy, which directly impact performance in high-precision applications. Precision is often measured by the stage’s minimum scale resolution, typically between 0.01mm and 0.03mm or finer, determining the smallest movement it can reliably produce. Accuracy depends on factors like the guide mechanism—such as crossed-roller bearings or dovetail slides—that minimize backlash and play. Manufacturing tolerances and machining quality also play crucial roles; tighter tolerances mean better positional accuracy. Environmental factors like temperature changes and vibrations can reduce effective accuracy, so stability features and suitable materials are essential. Additionally, calibration tools like micrometer heads help verify and fine-tune the stage’s position, ensuring excellent precision during operation.

Load Capacity Requirements

Selecting the right linear translation stage involves guaranteeing it can handle the maximum loads you’ll place on it without compromising performance or longevity. I always verify that the stage’s maximum load capacity exceeds the weight of my equipment or sample, preventing mechanical failure or deformation. It’s important to contemplate dynamic loads if the stage will move rapidly or repeatedly, not just static weight. I also check the bearings and sliding mechanisms, as high-quality components support heavier loads with smoother operation. Additionally, I verify load limits at each axis—X, Y, and Z—since they can differ. To ensure durability, I choose a stage with a load capacity 20-50% higher than my maximum expected load, providing a reliable safety margin for long-term use.

Travel Range Options

Travel range options for linear translation stages typically span from just a few millimeters to several hundred millimeters, depending on the specific application. If you need high precision with minimal displacement, shorter ranges like 13mm or 25mm are ideal, providing accurate control over small movements. For tasks requiring greater flexibility, longer ranges such as 90mm or 112mm allow for more extensive positioning but might slightly compromise accuracy or stability. When choosing a stage, consider your maximum displacement needs and whether future adjustments could require more travel. Larger ranges often mean heavier, more complex stages, which can affect portability and fine control. Balancing your application’s precision demands with movement requirements is key to selecting the right travel range.

Material Durability

Durability is a critical factor when evaluating linear translation stages, especially in demanding environments. Choosing materials like anodized aluminum alloys or high-strength aluminum ensures resistance to corrosion, wear, and environmental stress, extending the stage’s lifespan. High-quality machining and specialized surface treatments further enhance durability by stabilizing moving components and preventing premature wear. Materials with high stiffness and low thermal expansion, such as aluminum alloys, help maintain precise positioning despite temperature fluctuations. Additionally, wear-resistant bearings and sliding components reduce maintenance needs and prevent backlash over time. A robust construction combined with protective surface coatings enables these stages to withstand rigorous industrial conditions, guaranteeing consistent performance and longevity. Prioritizing material durability guarantees a reliable, stable, and long-lasting translation stage suited for demanding applications.

Mounting Compatibility

When choosing a linear translation stage, guaranteeing mounting compatibility is vital to achieving reliable and secure operation. I check that the mounting holes and patterns match my existing equipment to avoid complicated modifications. It’s important to confirm the stage’s mounting surface can handle the load capacity and weight distribution of my setup. Supporting standard interfaces like through-hole, T-slot, or threaded holes makes integration easier. I also verify that the maximum load capacity aligns with the weight of my components or specimens to prevent mounting failure. Additionally, I consider whether the stage supports extra mounting accessories or adapters, which can offer more installation flexibility. Proper mounting compatibility ensures stability, safety, and precise movement, making it a essential factor in my selection process.

Frequently Asked Questions

What Are the Typical Load Capacities for These Linear Stages?

Typically, load capacities for linear stages range from a few grams to several hundred kilograms, depending on their design and application. For precision work, I usually see stages supporting around 5 to 50 kilograms, while heavier-duty models can handle up to 200 kilograms or more. It’s essential to match the stage’s capacity to your specific load requirements to guarantee smooth, accurate movement without risking damage or inaccuracies.

How Do Environmental Factors Affect Stage Performance?

Environmental factors can substantially impact stage performance, much like wind can sway a tightrope walker. I’ve seen dust and debris clog delicate components, causing jerky movements or misalignments. Temperature fluctuations can cause materials to expand or contract, affecting precision. Humidity can lead to corrosion or reduced lubrication. To keep my stages running smoothly, I always make certain they’re protected from these elements, just like safeguarding a delicate instrument from the elements.

Are There Compatibility Issues With Specific Equipment?

Yes, there can be compatibility issues with specific equipment. I always double-check the specifications of the translation stage and my existing setup to verify they match. Sometimes, mounting interfaces or control systems may not align perfectly, causing delays or malfunctions. To avoid surprises, I consult manufacturer guidelines or technical support before integrating new equipment. This way, I ensure smooth operation and reliable performance in my experiments.

What Maintenance Is Required for Optimal Operation?

To keep your linear translation stages running smoothly, I recommend regularly cleaning the rails and guides to prevent debris buildup. Lubricate moving parts as specified by the manufacturer to reduce friction and wear. Check for any misalignment or loose screws periodically, and make certain that the stage operates within its specified load capacity. Performing these simple maintenance tasks helps maintain precision and prolongs the lifespan of your equipment.

Can These Stages Be Integrated With Automation Systems?

Absolutely, these stages can be integrated with automation systems—if you enjoy a bit of technological ballet. Modern linear translation stages come with compatible interfaces, control modules, and software that sync seamlessly with automation. I’ve seen engineers dance with this synergy, transforming static setups into dynamic marvels. So yes, you can automate with ease, turning your precision stage into the star performer of your automated choreography.

Conclusion

Choosing the right linear translation stage combines precision with ease of use, much like balancing accuracy with reliability. While some prioritize smooth movement, others focus on compact design. It’s easy to get caught up in specs, but remember, the best stage for you aligns with your specific needs—because in precision work, perfection isn’t just about the equipment, but how well it adapts to your craft. After all, precision is only as good as its application.