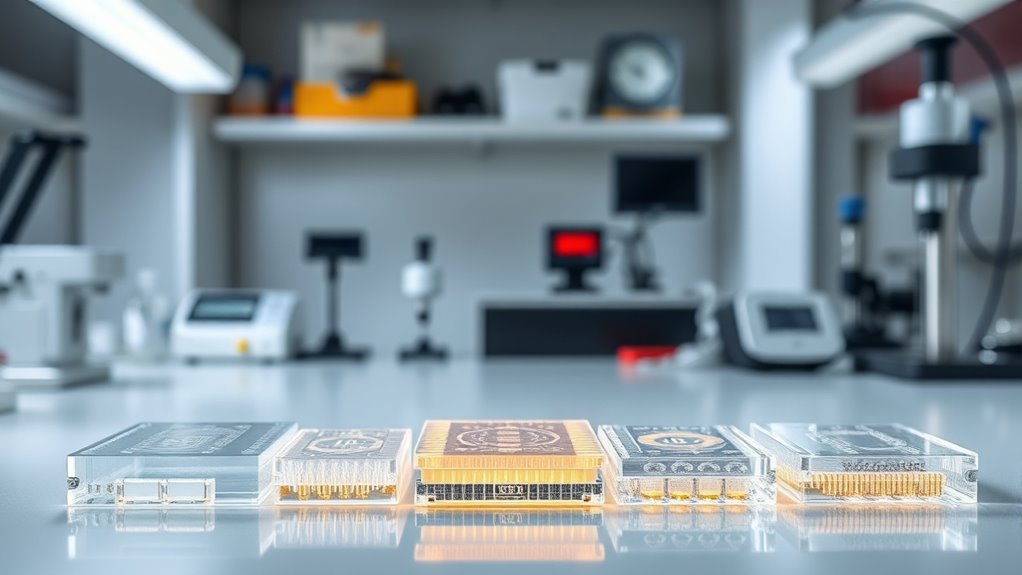

I’ve reviewed the top microfluidic chip fabrication kits for 2025, noting their precision, ease of use, and safety features. These kits include options like the Chip Quik REMKIT4.5 and SMD/SMT removal alloys, designed for accurate, low-temperature soldering and complex multilayer repairs. They’re compatible with lead-free processes and support various materials, making microfluidic device fabrication more efficient and reliable. Stick around, and you’ll discover which essentials can elevate your manufacturing process.

Key Takeaways

- Advanced kits feature high-precision alignment tools and materials supporting sub-micrometer resolution for detailed microfluidic device fabrication.

- Compatibility with diverse substrates like polymers, glass, and silicon ensures versatile and reliable manufacturing options.

- User-friendly interfaces, step-by-step instructions, and comprehensive support simplify complex fabrication processes for all skill levels.

- Reusable alloy sticks and environmentally compliant materials promote safe, sustainable, and cost-effective microfluidic production.

- Kits designed for seamless integration with existing workflows enable precise, efficient, and scalable chip manufacturing in 2025.

Fast Chip Kit for Quik SMD Removal with a Low Temperature Alloy

If you’re looking for a safe and efficient way to remove surface-mount devices without risking damage to the PCB, the Fast Chip Kit for Quik SMD Removal is an excellent choice. Its low-temperature alloy melts at just 136°F, making desoldering easier and safer. The kit lets you remove QFPs, PLCCs, SOICs, and other chips with minimal heat, reducing stress on components and pads. It’s cost-effective, containing enough alloy for about 8-10 SMDs. Users find it flows well, melts quickly, and simplifies removing factory lead-free solder. Plus, it’s user-friendly, making rework faster and safer for hobbyists and professionals alike.

Best For: hobbyists, technicians, and DIY repair enthusiasts seeking a safe, low-temperature, and efficient method for removing surface-mount devices without damaging the PCB.

Pros:

- Melts at just 136°F, reducing thermal stress on components and boards.

- Easy to use with good flow properties, enabling quick and clean SMD removal.

- Cost-effective kit with enough alloy for roughly 8-10 SMDs, ideal for small repair projects.

Cons:

- Included flux can be stiff, burn easily, or arrive damaged, requiring additional supplies.

- Alloy may be brittle if stored improperly or if a defective batch is received, risking breakage.

- Small quantity of flux may be insufficient for larger projects; larger amounts are recommended for extensive work.

Chip Quik SMD1NL SMD Removal Kit (Same as the SMD1 with lead-free alloy)

The Chip Quik SMD1NL SMD Removal Kit is an excellent choice for professionals and hobbyists who need to safely and effectively remove lead-free surface-mount devices from circuit boards. This kit includes 2.5 feet of lead-free removal alloy, flux, and alcohol pads, making solder removal straightforward and clean. Its silver-colored alloy ensures compatibility with lead-free soldering processes, while the included tools simplify the task. With high customer ratings and a compact design, it’s perfect for precise PCB repairs and microfluidic chip fabrication. Plus, it requires no batteries, making it easy to use anywhere. Overall, it’s a reliable, eco-friendly option for lead-free SMD removal.

Best For: electronics professionals and hobbyists needing a safe, eco-friendly solution for lead-free SMD removal from circuit boards.

Pros:

- Includes 2.5 feet of lead-free removal alloy, flux, and alcohol pads for comprehensive SMD removal.

- Compatible with lead-free soldering processes, ensuring reliable and safe operation.

- Compact and easy to use anywhere, with no batteries required.

Cons:

- Might require some practice for precise removal, especially for very small or densely packed components.

- Limited to surface-mount device removal; not suitable for through-hole components.

- Slightly higher cost compared to basic solder removal tools lacking alloy or flux.

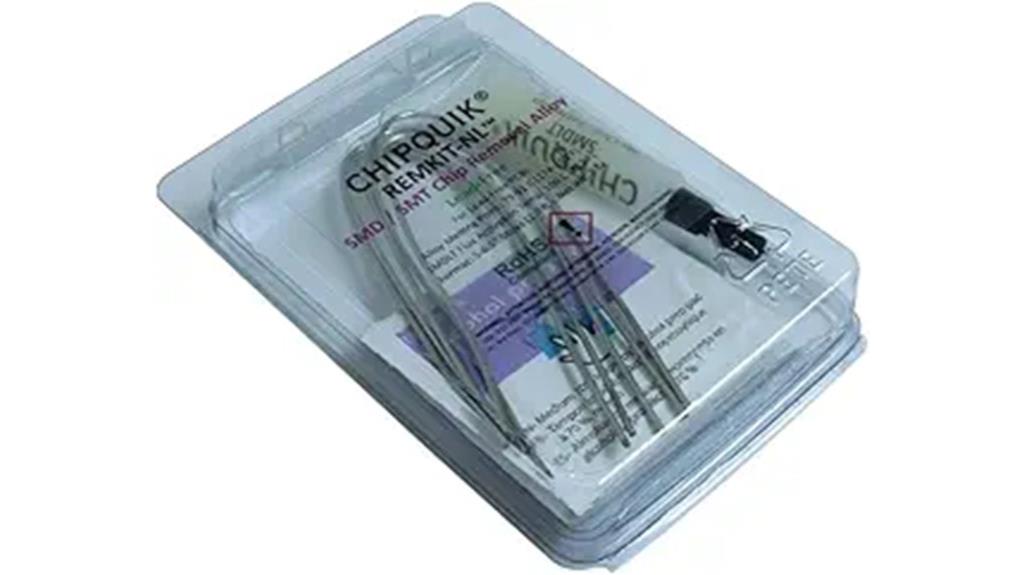

Chip Quik REMKIT SMD/SMT Chip Removal Alloy (REMKIT)

Chip Quik REMKIT SMD/SMT Chip Removal Alloy is an ideal choice for technicians and hobbyists who need a precise, low-temperature solution for removing surface-mount and through-hole components without damaging the PCB. This desoldering alloy, manufactured by Chip Quik®, includes flux and weighs about 0.8 ounces. It melts at a low temperature, keeping solder wet longer and easing component removal. Users praise its effectiveness in reducing damage, especially on complex multi-layer boards. To get the best results, apply flux, melt the alloy into solder joints, and gently remove components. It’s a reliable, efficient tool for delicate repairs and rework in microfluidic chip fabrication.

Best For: electronics technicians and hobbyists seeking a low-temperature, precise tool for safely removing surface-mount and through-hole components without damaging PCBs.

Pros:

- Facilitates delicate removal of components with minimal risk of PCB damage

- Low melting temperature keeps solder wet longer for easier removal

- Reusable leftover slag allows for cost-effective rework

Cons:

- Limited quantity per kit may require multiple purchases for extensive repairs

- Alloy can stiffen at higher temperatures, requiring temperature adjustments during use

- Sticky flux may need additional cleaning or alternative flux for optimal results

Chip Quik REMKIT4.5-NL SMD/SMT Chip Removal Kit

Designed for professionals and hobbyists who need precise removal of surface-mount devices, the Chip Quik REMKIT4.5-NL offers an efficient solution with its low-melting-point alloy and no-clean flux. The kit includes nine sticks of alloy, totaling 4.5 feet, with a melting point between 79-91°C. The included SMDLT no-clean tack flux activates at 100°C, ensuring clean removal without residue. Made by Chip Quik, it’s RoHS 3 and REACH compliant, and highly rated for ease of use and effectiveness. Whether you’re repairing or reworking, this kit simplifies SMD/SMT chip removal, making it a valuable addition to any microfluidic fabrication toolkit.

Best For: electronics hobbyists and professionals needing efficient, precise removal of surface-mount devices from circuit boards.

Pros:

- Easy to use with no-clean flux that leaves minimal residue

- Melting alloy operates effectively at low temperatures (79-91°C)

- Includes enough material (4.5 feet of alloy) for multiple applications

Cons:

- Requires careful handling due to hot alloy and flux activation temperature

- Not suitable for removing very large or heavily soldered components

- Limited to surface-mount device removal; not intended for other soldering tasks

Chip Quik REMKIT4.5 SMD/SMT Chip Removal Alloy With Flux Kit (REMKIT4.5)

If you’re working with surface-mount devices and need a safe, low-temperature method for removing chips, the Chip Quik REMKIT4.5 offers an excellent solution. This kit includes a leaded solder alloy that melts at just 58°C, minimizing heat damage, along with a no-clean tack flux to facilitate easy removal. The 4.5-foot alloy comes in six-and-a-half-inch sticks, making it easy to handle and store. With its reliable performance, the REMKIT4.5 is suitable for both professionals and hobbyists, ensuring precise, safe, and efficient chip removal without risking component damage or excessive heat.

Best For: hobbyists, electronics technicians, and professionals seeking a safe and efficient method to remove surface-mount devices without damaging components or applying excessive heat.

Pros:

- Melts at a low temperature of 58°C (136°F), reducing risk of heat damage

- Includes no-clean tack flux for easy and clean removal of chips

- Easy to handle, store, and suitable for both professional and DIY use

Cons:

- Limited to surface-mount components; not suitable for through-hole repairs

- Requires careful handling of the alloy and flux to avoid spills or waste

- May need additional tools for complete removal of larger or stubborn chips

Chip Quik REM4.5 SMD/SMT Chip Removal Alloy 4.5 FT (REM4.5)

For those working on microfluidic chip fabrication, Chip Quik REM4.5 stands out as an essential tool for efficiently removing SMD and SMT components. This low melting point alloy, with a melting temperature of about 58°C, easily melts and blends with existing solder, making desoldering straightforward and safe for delicate circuits. Packaged in 4.5-foot sticks, it’s economical for multiple uses. The included no-clean tack flux activates at 100°C, ensuring clean removal. Users praise its effectiveness on stubborn joints and complex assemblies. It’s a reliable, versatile option for precise desoldering, helping prevent damage and simplifying your microfluidic chip assembly process.

Best For: electronics technicians and microfluidic chip fabricators seeking efficient, low-temperature removal of SMD and SMT components without damaging delicate circuits.

Pros:

- Melts at a low temperature of approximately 58°C, reducing risk to sensitive components

- Blends well with existing solder, enabling clean and quick desoldering

- Comes in economical 4.5-foot sticks suitable for multiple uses

Cons:

- May have slightly less adhesion to soldering irons compared to other low melt alloys

- Requires thorough cleaning of residual alloy before re-soldering

- Higher price point compared to standard solder, which may impact cost for frequent users

Chip Quik REMKIT-NL SMD/SMT Chip Removal Alloy LF (REMKIT-NL)

The Chip Quik REMKIT-NL SMD/SMT Chip Removal Alloy LF stands out as an essential tool for electronics professionals and hobbyists seeking a safe, low-temperature way to remove surface-mount devices. Designed specifically for desoldering SMD components, it melts at just 79-91°C, reducing heat damage risks. The kit includes 2.7 feet of alloy sticks, low-temp flux, and alcohol pads for cleaning. Its lead-free composition ensures safer handling and environmental compliance. With a user rating of 4.6 stars, it’s reliable for precise, efficient removal. Perfect for delicate microfluidic chip fabrication, this kit simplifies the process while protecting sensitive components.

Best For: electronics professionals and hobbyists seeking a safe, low-temperature method to remove surface-mount devices with minimal risk of heat damage.

Pros:

- Low melting point (79-91°C) reduces risk of damage to sensitive components

- Lead-free and environmentally friendly, ensuring safer handling and disposal

- Includes all necessary tools (alloy sticks, flux, alcohol pads) for a complete desoldering solution

Cons:

- Limited to SMD component removal; not suitable for through-hole components

- May require some practice for precise application, especially for small or delicate parts

- Slightly higher cost compared to traditional solder removal methods

Factors to Consider When Choosing Microfluidic Chip Fabrication Kits

When selecting a microfluidic chip fabrication kit, I focus on key factors that guarantee it meets my project needs. Compatibility with my design, precision, and material compatibility are essential, along with keeping costs manageable. Ease of use also plays a big role in how smoothly I can move from concept to finished chip.

Compatibility With Design

Choosing a microfluidic chip fabrication kit requires careful attention to how well it aligns with your specific design features. I look for kits that support the materials I plan to use, whether PDMS, glass, or thermoplastics. It’s also essential that the kit includes compatible bonding and sealing methods suited to my channel geometries and surface treatments. Customizable options are a plus, allowing me to match the dimensions and complex features of my design. I verify whether the fabrication processes, like soft lithography or micromachining, are compatible with the kit’s tools and procedures. Additionally, adaptable components are important for handling unique design requirements or multi-layer structures. Ensuring compatibility helps streamline the manufacturing process and guarantees the final chip meets my specifications precisely.

Precision and Resolution

Achieving high precision and resolution in microfluidic chip fabrication hinges on selecting methods capable of creating features below 10 micrometers. Photolithography excels here, offering sub-micrometer accuracy essential for precise fluid control. Soft lithography, while more accessible, typically produces features around 10 micrometers, which may suffice for less demanding applications. Material choice also impacts resolution; SU-8 and PDMS differ in their patterning capabilities and surface properties, influencing the smallest achievable features. Accurate multilayer alignment is critical to prevent misregistration and maintain resolution integrity. Additionally, the quality of masks or templates plays a significant role—high-quality masks enable finer feature definition. Balancing these factors ensures you select a kit that meets your resolution needs for successful microfluidic device fabrication.

Material Compatibility

Selecting the right microfluidic fabrication kit requires careful consideration of material compatibility to guarantee your device functions reliably. You need to verify the kit’s materials are chemically compatible with your intended fluids to prevent unwanted reactions or damage to microchannels. Confirm that the substrate and bonding materials can withstand the solvents and chemicals involved in your specific application. It’s also important to take into account whether the kit supports materials like polymers, glass, or silicon, which might be essential for your device’s performance. Additionally, the materials should integrate seamlessly with your existing fabrication processes, especially if you’re designing multilayer or complex structures. Overall, choosing materials suited to your thermal, chemical, and mechanical needs is vital for ensuring durability and functionality.

Budget Considerations

Budget considerations play a crucial role in selecting a microfluidic fabrication kit, as costs can vary widely depending on the features and materials included. Budget options often have limited features and lower material quality, while higher-priced kits provide advanced materials and more precise tools, enhancing project quality. Your budget may also influence the fabrication methods you choose, such as soft lithography versus more expensive techniques like injection molding. It’s important to think long-term—consider potential additional costs for materials or upgrades needed for complex designs. Striking a balance between budget and functionality ensures you select a kit that offers reliable performance without overspending on unnecessary features. Carefully evaluating these factors helps you make a cost-effective choice aligned with your project’s needs.

Ease of Use

When choosing a microfluidic chip fabrication kit, ease of use is a critical factor that can determine how smoothly your project progresses. A user-friendly kit should include clear, step-by-step instructions suitable for various experience levels, reducing confusion and errors. Pre-measured or ready-to-use components save time and lower the risk of handling mistakes. Intuitive interfaces, whether through straightforward software or manual procedures, help streamline operations. Kits with automated or semi-automated features make complex processes more accessible, even for beginners. Additionally, low assembly complexity and simple troubleshooting contribute to faster learning curves and more consistent results. Prioritizing ease of use guarantees efficient fabrication, minimizes frustration, and enhances overall productivity in your microfluidic projects.

Support and Resources

Support and resources play a pivotal role in guaranteeing your microfluidic chip fabrication process runs smoothly. Reliable support includes detailed manuals, troubleshooting guides, and accessible technical assistance, helping you overcome challenges quickly. Online tutorials, forums, and video demonstrations can boost your understanding and skill development, making complex procedures easier to master. Manufacturers that provide responsive customer service and technical support reduce downtime, keeping your project on track. The availability of replacement parts, consumables, and upgrade options ensures your system remains operational and adaptable as your needs evolve. Additionally, clear documentation on safety protocols, material handling, and maintenance procedures helps prevent errors and promotes a safe working environment. Overall, strong support and resources are essential for efficient, safe, and successful microfluidic chip fabrication.

Frequently Asked Questions

What Safety Precautions Are Necessary When Using Microfluidic Fabrication Kits?

When using microfluidic fabrication kits, I always prioritize safety by wearing gloves, goggles, and a lab coat to protect against chemicals and aerosols. I make sure proper ventilation and handle all materials with care, following the manufacturer’s instructions. It’s also essential to keep a fire extinguisher nearby and avoid eating or drinking in the workspace. Staying alert and trained helps me prevent accidents and maintain a safe working environment.

How Do Different Alloy Types Affect Chip Fabrication Accuracy?

Different alloy types fundamentally impact chip fabrication accuracy. I’ve found that alloys with uniform composition, like stainless steel, offer better precision because they resist deformation during fabrication. In contrast, alloys with variable properties, such as certain aluminum alloys, can cause inconsistencies due to uneven melting or expansion. Choosing the right alloy is vital for ensuring your microfluidic chips are precise, reliable, and meet your specific manufacturing standards.

Are There Environmentally Friendly Options for Microfluidic Chip Manufacturing?

Yes, there are environmentally friendly options I recommend exploring. I focus on biodegradable materials like certain bioplastics and paper-based substrates that reduce waste and emissions. These options are gaining popularity because they’re safe for the environment and still allow precise, effective microfluidic fabrication. I suggest considering sustainable polymers and eco-friendly etching processes, which help minimize your manufacturing footprint while keeping your chips high quality.

What Is the Typical Lifespan of a Standard Microfluidic Fabrication Kit?

A standard microfluidic fabrication kit usually lasts about six months to a year, depending on how often I use it and the care I take. I make sure to store the components properly and follow the manufacturer’s instructions to extend its lifespan. If I’m working on a large project, I might need to replace parts sooner, but generally, with proper maintenance, it remains reliable throughout its lifespan.

Can These Kits Be Used for Creating Custom Microfluidic Designs?

Did you know that over 60% of researchers customize microfluidic designs for their projects? Yes, these kits are perfect for creating custom microfluidic devices. I’ve used them myself and found they offer flexible components and user-friendly interfaces, making personalized designs achievable without extensive technical expertise. So, whether you’re prototyping or refining a specific experiment, these kits enable you to tailor microfluidic chips to your exact needs.

Conclusion

So, choosing the right microfluidic chip fabrication kit is like finding the perfect key to unbolt your innovation’s potential. Each kit offers its own unique magic, whether it’s precision, ease, or versatility. Trust your instincts and consider your specific needs—because with the right tool in hand, you’ll turn complex ideas into smooth, flowing realities. Let your creativity flow effortlessly, turning each fabrication challenge into a masterpiece of microfluidic mastery.