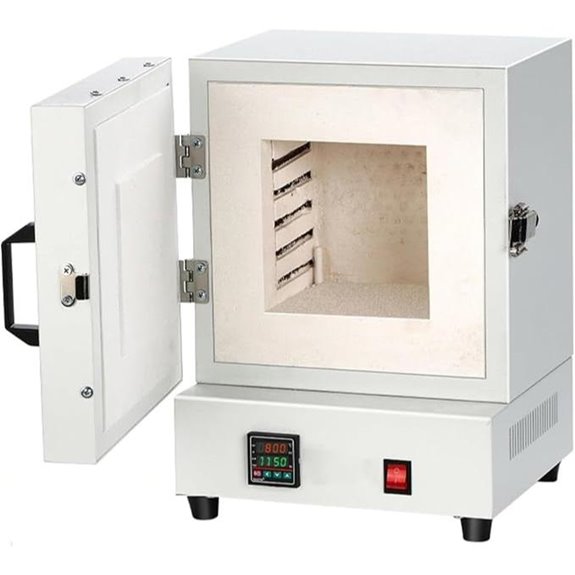

If you’re looking for the 15 best muffle furnaces of 2026, I’ve got you covered. I’ve researched top models ranging from compact units ideal for jewelry and small-scale experiments to high-capacity, high-temperature systems perfect for industrial and research purposes. Many feature advanced PID controls, durable alumina chambers, and safety features. Whether you need precise temperature control or powerful heating, these options will fit your needs. Keep exploring to find out which furnace is best for you.

Key Takeaways

- Top models feature precise PID control with programmable multi-stage heating curves for accurate temperature profiles.

- High-quality alumina ceramic chambers ensure durability and chemical resistance at temperatures up to 1700°C.

- Safety features like alarms, auto shut-off, and reinforced doors are standard in premium muffle furnace options.

- Variations in chamber size and capacity cater to diverse industrial, laboratory, and research needs.

- Advanced models include AI-controlled programming and rapid heating for efficient high-temperature processing.

| Muffle Furnace 1050°C with PID Controller for Thermal Treatments |  | Versatile Lab Solution | Maximum Temperature: 1050°C | Chamber Capacity: 1L | Programmable Control: 30 segments | VIEW LATEST PRICE | See Our Full Breakdown |

| 1200℃ Lab Muffle Furnace with Vacuum Pump |  | High-Temperature Precision | Maximum Temperature: 1200°C | Chamber Capacity: 1L | Programmable Control: 30-50 segments, self-tuning | VIEW LATEST PRICE | See Our Full Breakdown |

| Muffle Furnace 1050°C with PID Controller for Thermal Treatments |  | Metal & Ceramic Expert | Maximum Temperature: 1050°C | Chamber Capacity: 1L | Programmable Control: 30 segments | VIEW LATEST PRICE | See Our Full Breakdown |

| HNZXIB 1700℃ Lab Electric Muffle Furnace (1L) |  | Industrial Powerhouse | Maximum Temperature: 1700°C | Chamber Capacity: 1L | Programmable Control: 50 segments, AI algorithms | VIEW LATEST PRICE | See Our Full Breakdown |

| SH Scientific Muffle Furnace 11L 1050°C 220V |  | Cost-Effective Choice | Maximum Temperature: 1050°C | Chamber Capacity: 11L | Programmable Control: Programmable, multi-stage | VIEW LATEST PRICE | See Our Full Breakdown |

| HNZXIB 1700℃ Laboratory Muffle Furnace (27L) |  | Advanced Atmosphere Control | Maximum Temperature: 1700°C | Chamber Capacity: 27L | Programmable Control: 50 segments, programmable | VIEW LATEST PRICE | See Our Full Breakdown |

| HNZXIB 1700℃ Lab Electric Muffle Furnace (1L) |  | Scientific Reliability | Maximum Temperature: 1700°C | Chamber Capacity: Not specified (large chamber) | Programmable Control: 50 segments, programmable | VIEW LATEST PRICE | See Our Full Breakdown |

| High-Temperature Muffle Furnace 2102℉ (1150℃) |  | Extreme Heat Capacity | Maximum Temperature: 1150°C | Chamber Capacity: Large (size not specified) | Programmable Control: Not specified (digital display with control) | VIEW LATEST PRICE | See Our Full Breakdown |

| MG Scientific Rectangular Muffle Furnace |  | Compact and Robust | Maximum Temperature: 900°C | Chamber Capacity: 225x100x100mm | Programmable Control: Digital control | VIEW LATEST PRICE | See Our Full Breakdown |

| Muffle Furnace 2L/1200℃ for High-Temp Material Processing |  | High-Temp Efficiency | Maximum Temperature: 1200°C | Chamber Capacity: 2L | Programmable Control: Multi-stage programmable | VIEW LATEST PRICE | See Our Full Breakdown |

| 1200℃ Lab Muffle Furnace with Vacuum Pump |  | Research-Grade Performance | Maximum Temperature: 1200°C | Chamber Capacity: 1L | Programmable Control: 30-50 segments, self-tuning | VIEW LATEST PRICE | See Our Full Breakdown |

| Laboratory Muffle Furnace 1100℃ for Jewelry Processing |  | Jewelry & Small-Scale | Maximum Temperature: 1100°C | Chamber Capacity: Not specified (compact) | Programmable Control: Digital, programmable | VIEW LATEST PRICE | See Our Full Breakdown |

| Electric Kiln for Jewelry Metal Casting Pottery |  | Small Batch Precision | Maximum Temperature: 1150°C | Chamber Capacity: Not specified (small) | Programmable Control: Digital temperature control | VIEW LATEST PRICE | See Our Full Breakdown |

| Laboratory Muffle Furnace 1100℃ for Jewelry Processing |  | Heavy-Duty Durability | Maximum Temperature: 1100°C | Chamber Capacity: Not specified (compact) | Programmable Control: Intelligent control panel | VIEW LATEST PRICE | See Our Full Breakdown |

| 2000W Ceramic Laboratory Muffle Furnace for Metal Melting |  | High-Performance Furnace | Maximum Temperature: 2000°C | Chamber Capacity: Not specified (large, for high-temp) | Programmable Control: Multi-stage, programmable | VIEW LATEST PRICE | See Our Full Breakdown |

More Details on Our Top Picks

Muffle Furnace 1050°C with PID Controller for Thermal Treatments

If you’re looking for a reliable muffle furnace for precise thermal treatments, the Muffle Furnace 1050°C with PID Controller stands out as an excellent choice. Its 1-liter chamber and 30-segment programmable PID control ensure accurate temperature regulation for various applications like annealing, sintering, melting, and more. Lightweight at just 25kg, it’s perfect for lab bench use or glove boxes. The alumina ceramic chamber provides high-temperature stability, and the exhaust outlet promotes excellent outgassing. Supported by a trusted US-based team and a one-year warranty, this furnace offers versatile, efficient, and dependable performance for dental, jewelry, ceramic, and metal work.

- Maximum Temperature:1050°C

- Chamber Capacity:1L

- Programmable Control:30 segments

- Construction Material:Alumina ceramic

- Safety Features:Exhaust air outlet, support

- Application Scope:Metal, ceramic, jewelry

- Additional Feature:Alumina ceramic chamber

- Additional Feature:Lightweight 25kg design

- Additional Feature:30 programmable segments

1200℃ Lab Muffle Furnace with Vacuum Pump

The 0℃ Lab Muffle Furnace with Vacuum Pump stands out as an excellent choice for researchers and laboratories needing precise temperature control combined with advanced atmosphere management. Its design features lightweight alumina ceramic fiber construction and a double-layer air-cooled structure, ensuring durability and safety. The furnace offers a maximum temperature of 1200℃ with intelligent PID self-tuning for automatic heating and cooling, reducing supervision. Equipped with a high-capacity vacuum pump supporting up to 600PA, it enables inert atmosphere processing like sintering and reduction. Its user-friendly interface, optional computer connectivity, and corrosion-resistant exterior make it ideal for scientific research, small-scale production, and industrial applications.

- Maximum Temperature:1200°C

- Chamber Capacity:1L

- Programmable Control:30-50 segments, self-tuning

- Construction Material:Alumina ceramic fiber

- Safety Features:Over-pressure, alarms, auto shutoff

- Application Scope:Scientific research, sintering

- Additional Feature:Optional RS-485 interface

- Additional Feature:Vacuum capacity up to 600PA

- Additional Feature:Double-layer air-cooled structure

Muffle Furnace 1050°C with PID Controller for Thermal Treatments

Designed for precise metal heat treatments, the Muffle Furnace 1050°C with PID Controller stands out as an ideal choice for laboratories and professionals requiring accurate temperature control. Its 1-liter alumina ceramic chamber ensures high-temperature stability, while the 30-segment PID controller offers precise programming for complex heating profiles. Suitable for annealing, sintering, melting, and other thermal processes, it’s versatile across dental, jewelry, ceramic, and metal applications. Lightweight at just 25kg and powered by 110V, it’s perfect for benchtop use. With CE and ISO certification, along with dedicated US support and a one-year warranty, this furnace combines reliability with ease of operation.

- Maximum Temperature:1050°C

- Chamber Capacity:1L

- Programmable Control:30 segments

- Construction Material:Alumina ceramic

- Safety Features:Exhaust outlet, safety switch

- Application Scope:Metal, ceramic, jewelry, research

- Additional Feature:Alumina ceramic chamber

- Additional Feature:Lightweight 25kg unit

- Additional Feature:Universal metal/ceramic use

HNZXIB 1700℃ Lab Electric Muffle Furnace (1L)

For researchers and industry professionals seeking precise high-temperature control, the HNZXIB 1700℃ Lab Electric Muffle Furnace (1L) is an outstanding option. It reaches up to 1700℃, ideal for materials science, ceramic sintering, and metal heat treatments. Its high-purity alumina lining guarantees safety and purity, while the durable carbon steel body resists rust. The furnace features advanced AI-controlled programming with 50 customizable temperature curves, ensuring accurate, overshoot-free heating. Uniform temperature distribution within ±1.5℃ and extensive safety features—like over-temperature protection—make it reliable for demanding applications. Its user-friendly design supports research and industrial use with consistent, precise results.

- Maximum Temperature:1700°C

- Chamber Capacity:1L

- Programmable Control:50 segments, AI algorithms

- Construction Material:Alumina ceramic fiber, steel casing

- Safety Features:Over-temperature alarm, safety circuitry

- Application Scope:Material science, industrial

- Additional Feature:50-segment programmable curves

- Additional Feature:Silicon carbide heating elements

- Additional Feature:Dual over-temperature protection

SH Scientific Muffle Furnace 11L 1050°C 220V

If you’re seeking a reliable muffle furnace capable of precise high-temperature treatments, the SH Scientific Muffle Furnace with an 11L chamber and a maximum temperature of 1050°C stands out as a top choice. It heats quickly, reaching 800°C in under 40 minutes, and offers uniform temperature distribution thanks to heating from three sides. Designed for various materials like metals, ceramics, and plastics, it’s perfect for annealing, sintering, melting, and more. Its durable, budget-friendly design features programmable controls and a lightweight build, making it easy to operate and ideal for laboratory applications requiring consistent, high-temperature processing.

- Maximum Temperature:1050°C

- Chamber Capacity:11L

- Programmable Control:Programmable, multi-stage

- Construction Material:Steel shell, refractory lining

- Safety Features:Over-temperature protection

- Application Scope:Metal, ceramic, lab analysis

- Additional Feature:Flap door design

- Additional Feature:800°C in under 40 min

- Additional Feature:Multiple size variants

HNZXIB 1700℃ Laboratory Muffle Furnace (27L)

The HNZXIB 1700℃ Laboratory Muffle Furnace stands out for its precise AI intelligent program control, making it an excellent choice for researchers and technicians who need reliable, customizable heating cycles. Its 27L ceramic chamber ensures uniform temperature distribution, supporting applications like ceramic sintering, metal annealing, and ash testing. It heats rapidly to 1700℃ in under 30 minutes and features a 50-segment programmable temperature curve for tailored heating and cooling. Built with high-quality alumina ceramic fiber and durable resistance wires, it offers long-lasting performance. Safety is a priority, with alarms, auto shut-off, and reinforced door latches, making it both efficient and secure for extensive laboratory use.

- Maximum Temperature:1700°C

- Chamber Capacity:27L

- Programmable Control:50 segments, programmable

- Construction Material:Alumina ceramic fiber

- Safety Features:Over-temperature alarm, safety protections

- Application Scope:Research, metallurgy, ceramics

- Additional Feature:50-segment programmable control

- Additional Feature:High-purity alumina chamber

- Additional Feature:Automated safety features

HNZXIB 1700℃ Lab Electric Muffle Furnace (1L)

Engineered for high-precision scientific and industrial applications, the HNZXIB 1700°C Laboratory Electric Muffle Furnace stands out with its ability to reach a maximum temperature of 1700°C, ensuring reliable performance in material science, ceramic sintering, and metal heat treatment. It features a lightweight high-purity alumina inner lining for safety and contamination prevention, while the durable carbon steel body resists rust. The double-layer insulated shell with air circulation cooling maintains stable high temperatures and surface safety. Equipped with advanced AI control, programmable curves, and automatic operation, it guarantees precise, overshoot-free heating. Its uniform temperature distribution and safety features make it a dependable choice for rigorous laboratory and industrial use.

- Maximum Temperature:1700°C

- Chamber Capacity:Not specified (large chamber)

- Programmable Control:50 segments, programmable

- Construction Material:Alumina ceramic, steel shell

- Safety Features:Over-temperature, break detection

- Application Scope:Scientific, industrial, research

- Additional Feature:50-segment programmable curves

- Additional Feature:Silicon molybdenum resistance wires

- Additional Feature:Anti-interference circuitry

High-Temperature Muffle Furnace 2102℉ (1150℃)

For professionals and serious hobbyists seeking reliable high-temperature performance, the High-Temperature Muffle Furnace 2102℉ (1150℃) stands out with its advanced four-sided surround heating technology. This guarantees even heat distribution, crucial for precise metalworking, casting, and enameling. Its large chamber (16×16×13.8cm) can handle multiple molds simultaneously, boosting efficiency. Made from durable, corrosion-resistant materials, it offers a long lifespan. The digital control system provides accurate temperature adjustments from 0 to 1150℃, with real-time monitoring for safe, consistent operation. Compact yet powerful, it’s perfect for both professional labs and dedicated hobbyist studios.

- Maximum Temperature:1150°C

- Chamber Capacity:Large (size not specified)

- Programmable Control:Not specified (digital display with control)

- Construction Material:High-temperature resistant materials

- Safety Features:Overheat protection, safety alarms

- Application Scope:Jewelry, metalworking, casting

- Additional Feature:Large chamber size

- Additional Feature:Four-sided surround heating

- Additional Feature:Digital real-time monitor

MG Scientific Rectangular Muffle Furnace

If you’re seeking a reliable furnace for precise scientific and industrial heating, the MG Scientific Rectangular Muffle Furnace stands out with its high maximum temperature of 900°C. Its robust construction features a thick mild steel outer shell finished with attractive stoving enamel, ensuring durability. The grooved refractory supporting heating elements, made from easily replaceable Kanthal wire, provide consistent heat. With a chamber size of 225x100x100 mm, it’s suitable for various experiments and industrial tasks. Powered by 220 volts, this brand-new, unopened furnace is ideal for laboratories and research facilities needing dependable high-temperature performance.

- Maximum Temperature:900°C

- Chamber Capacity:225x100x100mm

- Programmable Control:Digital control

- Construction Material:Refractory materials, steel casing

- Safety Features:Over-temperature, thermocouple break detection

- Application Scope:Demonstration, industrial

- Additional Feature:Refractory Kanthal wire

- Additional Feature:Compact 9x4x4 inch chamber

- Additional Feature:Suitable for demonstrations

Muffle Furnace 2L/1200℃ for High-Temp Material Processing

The Muffle Furnace 2L/1200℃ stands out as an ideal choice for laboratories and professionals who require precise high-temperature processing. With a maximum temperature of 1200°C, it’s perfect for sintering, annealing, and melting metals, ceramics, glass, and plastics. Its uniform temperature distribution and fast heating capabilities guarantee consistent results. The furnace features a microcomputer control system with multi-stage programming, making complex experiments straightforward. Its lightweight design, detachable components, and safety features like an exhaust device simplify maintenance. Reliable and easy to operate, this furnace provides accurate temperature control (±0.1°C), making it a valuable tool for high-temp material processing.

- Maximum Temperature:1200°C

- Chamber Capacity:2L

- Programmable Control:Multi-stage programmable

- Construction Material:Ceramic chamber, steel shell

- Safety Features:Over-temperature, safety protections

- Application Scope:Sintering, metal, ceramics

- Additional Feature:24-hour customer support

- Additional Feature:Detachable circuit design

- Additional Feature:Exhaust ash removal system

1200℃ Lab Muffle Furnace with Vacuum Pump

A 0℃ Lab Muffle Furnace with Vacuum Pump is an ideal choice for researchers and industrial professionals who need precise temperature control combined with effective atmosphere management. Its advanced lightweight alumina ceramic fiber guarantees durability and efficient insulation. The furnace features 30-50 segment programmable PID self-tuning, providing automatic heating and cooling without constant supervision. With a vacuum capacity up to 600PA and a maximum temperature of 1200℃, it’s perfect for atmosphere protection, preventing oxidation and decarbonization. Its user-friendly design includes a double-layer air-cooled structure, high-temperature resistant coating, and optional computer connectivity for control, data recording, and curve storage.

- Maximum Temperature:1200°C

- Chamber Capacity:1L

- Programmable Control:30-50 segments, self-tuning

- Construction Material:Alumina ceramic fiber

- Safety Features:Sealed chamber, safety alarms

- Application Scope:Scientific research, small batch

- Additional Feature:Double-layer air-cooled

- Additional Feature:Age-resistant exterior paint

- Additional Feature:Atmosphere protection design

Laboratory Muffle Furnace 1100℃ for Jewelry Processing

Jewelry artisans seeking precise temperature control and efficient processing will find the Laboratory Muffle Furnace 1100℃ an ideal choice, thanks to its rapid heating and advanced thermal insulation. It features a built-in intelligent burnout oven, melting furnace, and wax elimination functions, making it versatile for jewelry work. The furnace heats quickly, transfers heat efficiently, and reduces energy consumption, saving both time and costs. Equipped with a chimney for smoke venting, it ensures safe operation. Its full graphic control panel with fast-responding thermocouples allows accurate temperature adjustments, improving productivity and consistency in jewelry processing. This furnace is a reliable tool for professional-grade results.

- Maximum Temperature:1100°C

- Chamber Capacity:Not specified (compact)

- Programmable Control:Digital, programmable

- Construction Material:Stainless steel shell, ceramic lining

- Safety Features:Temperature safety, exhaust system

- Application Scope:Jewelry, metal, ceramics

- Additional Feature:Chimney for smoke vent

- Additional Feature:Full graphic control panel

- Additional Feature:Quick temperature response

Electric Kiln for Jewelry Metal Casting Pottery

If you’re seeking an electric kiln that delivers precise temperature control and uniform heating, this model stands out for jewelry makers, metal casters, and pottery artists alike. Its advanced 4-sided surround heating ensures even, efficient heat distribution, while intelligent control from 0 to 1150℃ prevents overheating. The 2000W high-performance element heats rapidly, and the sealed door reduces heat loss, lowering energy consumption. The bright digital display allows real-time monitoring and precise adjustments, giving you full control. With a 16×16×13.8cm chamber, it accommodates multiple molds simultaneously. This versatile kiln is perfect for jewelry casting, metal melting, pottery glazing, and small-scale production.

- Maximum Temperature:1150°C

- Chamber Capacity:Not specified (small)

- Programmable Control:Digital temperature control

- Construction Material:Steel and ceramic lining

- Safety Features:Over-temperature protection

- Application Scope:Jewelry, pottery, small-scale

- Additional Feature:Batch processing capacity

- Additional Feature:1150℃ maximum temp

- Additional Feature:Sealed furnace door

Laboratory Muffle Furnace 1100℃ for Jewelry Processing

For professionals who need reliable, high-performance heating in laboratory settings, the High-Temperature Laboratory Muffle Furnace 220V 4KW stands out as an excellent choice. Its stainless steel shell provides excellent thermal insulation, ensuring energy efficiency and durability. Made from heat-resistant materials, it maintains high temperature stability up to 1100°C, with uniform, rapid heating thanks to high thermal conductivity. Safety features like a top chimney for smoke discharge prevent odors and enhance user health. The intelligent control panel allows precise temperature and time adjustments, with a full graphic display and indicator lights for easy operation. This furnace is ideal for applications in dentistry, jewelry, and various laboratory processes.

- Maximum Temperature:1100°C

- Chamber Capacity:Not specified (compact)

- Programmable Control:Intelligent control panel

- Construction Material:Steel shell with insulation

- Safety Features:Smoke exhaust, safety controls

- Application Scope:Dentistry, jewelry, labs

- Additional Feature:Stainless steel shell

- Additional Feature:Intelligent control panel

- Additional Feature:Multiple application fields

2000W Ceramic Laboratory Muffle Furnace for Metal Melting

The 2000W Ceramic Laboratory Muffle Furnace stands out as an ideal choice for professionals requiring precise and reliable metal melting capabilities. Its advanced four-sided surround heating ensures even temperature distribution, while the intelligent control system allows accurate regulation from 0 to 1150℃. The digital display and high-precision sensors enable real-time monitoring, preventing overheating and uneven heating. Designed for batch processing, it features a spacious 16 x 16 x 13.8 cm cavity, perfect for small molds and multiple pieces. Built with durable, corrosion-resistant materials, it offers long-term reliability and energy efficiency, making it suitable for jewelry, dentistry, and metal treatment applications.

- Maximum Temperature:2000°C

- Chamber Capacity:Not specified (large, for high-temp)

- Programmable Control:Multi-stage, programmable

- Construction Material:Refractory ceramic chamber

- Safety Features:Over-temperature, safety alarms

- Application Scope:Metal, ceramics, small batch processing

- Additional Feature:Thick furnace wires

- Additional Feature:Precise digital display

- Additional Feature:Energy-efficient design

Factors to Consider When Choosing Muffle Furnaces

When selecting a muffle furnace, I consider key factors like temperature range and control precision to meet my specific needs. I also check the chamber material quality and verify it matches the power and voltage requirements of my setup. Safety features, such as overheat protections, are equally important to keep operations secure and reliable.

Temperature Range Options

Choosing the right temperature range for a muffle furnace is essential because it directly impacts its suitability for your specific materials and processes. Most furnaces offer ranges from around 800°C to 1700°C, so selecting one that matches your needs is imperative. If your work might expand to higher temperatures later, opt for a model with a maximum rating above your current requirements to guarantee flexibility. Precise temperature control within the chosen range is critical for tasks like sintering, annealing, or melting, where accuracy affects results. Some furnaces feature adjustable ramps and programmable heating curves, allowing complex temperature profiles. Ultimately, matching the furnace’s maximum temperature to your thermal process needs prevents overheating or underperformance, ensuring consistent, reliable results.

Control Precision Levels

Control precision levels in muffle furnaces considerably influence the accuracy and stability of your thermal processes. Higher precision is achieved through more programmable segments—30 or even 50—allowing for finer temperature adjustments tailored to specific needs. Digital temperature controllers equipped with filtering and anti-interference features ensure consistent readings, especially in electromagnetic environments. Using Type B thermocouples provides precise temperature measurements up to 1700°C, enhancing control accuracy. Multi-stage programmable curves enable complex heating and cooling profiles with minimal overshoot, ensuring consistent conditions throughout the process. Additionally, over-temperature protection and break detection systems are essential for maintaining safe and stable operation, preventing deviations that could compromise your results. These features collectively help you achieve reliable, precise thermal management.

Chamber Material Quality

The quality of the chamber material is a critical factor that directly affects a muffle furnace’s performance and longevity. I look for chambers made from high-temperature resistant alumina ceramic or other refractory materials, as these withstand extreme heat without degrading. High-quality materials also offer excellent thermal insulation, which helps reduce energy use and ensures even temperature distribution. Durability is key, especially for applications exceeding 1200°C, since a robust chamber prolongs the furnace’s lifespan. If I need to work in reactive or corrosive atmospheres, I prioritize materials with strong corrosion resistance. Additionally, the composition and density influence outgassing properties, which are essential for minimizing contamination during sensitive thermal processes. Overall, choosing the right chamber material ensures reliability and efficiency over time.

Power and Voltage Needs

When selecting a muffle furnace, it’s essential to confirm its power and voltage specifications align with your facility’s electrical system. Most high-temperature models range from 1kW to 4kW, so verify your power supply can handle this load. Check if the furnace requires 110V or 220V, and confirm that your electrical system matches to avoid needing extra transformers. High-power furnaces might need dedicated circuits to prevent overloads and maintain safety. Additionally, consider energy consumption, especially if you’ll use the furnace frequently or for extended periods, as this impacts operational costs. Ensuring the power and voltage specifications meet safety standards is fundamental to avoid electrical hazards and ensure reliable operation in your specific environment. Proper matching helps optimize performance and safety.

Safety and Overheat Protections

Ensuring safety in muffle furnace operation hinges on effective overheat protections that prevent damage and safeguard users. Modern furnaces feature alarms and automatic shutoff systems that activate when temperatures exceed safe limits, reducing risk. Dual protection mechanisms, like alarms combined with power cut-offs, are essential, especially at maximum temperatures, ensuring the furnace doesn’t overheat. Thermocouple break detection is another critical safety feature; it halts operation immediately if the sensor fails, preventing uncontrolled heating. Proper insulation and air-cooling mechanisms help keep surface temperatures within safe ranges, reducing burn risks. Additionally, choosing furnaces with safety certifications and adherence to international standards provides reassurance that overheat and safety protections are reliable, making operation safer for users and equipment alike.

Size and Capacity Choices

Choosing the right size and capacity for your muffle furnace directly impacts its effectiveness and safety during operation. I consider the internal chamber dimensions to ascertain enough space for your samples or materials, like 4x4x4 inches or larger for batch processing. You should select a capacity that matches your production volume, from small 1L chambers to larger 27L or 50-segment programmable models. It’s also important to evaluate whether the furnace fits comfortably within your workspace for easy placement and removal of items. Keep in mind that bigger furnaces typically require more power and may have longer heat-up times, which can affect efficiency. Matching the furnace size to your specific thermal needs—whether for jewelry, ceramics, metals, or research—helps optimize performance and workflow.

Heating Element Durability

The durability of a muffle furnace’s heating elements largely depends on the materials used and how well the furnace is designed. Materials like molybdenum and silicon carbide offer high resistance to oxidation and thermal stress, which extends their lifespan. Proper insulation and precise temperature control reduce stress on the elements, preventing early failure during high-temperature operations. Regular maintenance, including timely replacement of worn or damaged elements, helps avoid uneven heating and potential furnace breakdown. Using high-quality heating wires with thicker gauges increases their ability to withstand thermal cycling, boosting longevity. Additionally, an effective furnace design that ensures even heat distribution and safeguards against thermal shock plays a vital role in maintaining the integrity and durability of the heating elements over time.

Price and Budget Fit

When selecting a muffle furnace, balancing your budget with the features you need is key. I recommend comparing initial costs to verify the model fits your financial constraints. But don’t forget to contemplate long-term value—cheaper units might save money upfront but could incur higher maintenance or replacement costs later. Evaluate whether the furnace’s features match your specific application without paying for unnecessary extras. Remember to account for additional expenses like shipping, installation, and future upgrades, as these can add up. If a higher-priced furnace offers better durability or energy efficiency, it might be worth the investment. Also, check if financing or leasing options are available, making more expensive models more accessible within your budget. This way, you find a solution that balances cost with performance.

Frequently Asked Questions

What Safety Features Are Essential in High-Temperature Muffle Furnaces?

Safety features like automatic shut-off, over-temperature protection, and reliable insulation are vital in high-temperature muffle furnaces. I always look for these because they prevent accidents and protect both users and samples. A sturdy door latch, proper ventilation, and clear temperature controls are also essential. These features ensure safe operation, reduce risks, and give me peace of mind during intense or prolonged use.

How Energy-Efficient Are Modern Muffle Furnace Models?

Did you know that modern muffle furnaces can be up to 30% more energy-efficient than older models? I’ve found that today’s designs incorporate advanced insulation and precise temperature controls, which considerably cut energy consumption. This means I save on electricity bills and reduce my environmental impact. If you’re looking for reliable, efficient equipment, I recommend choosing models with these features—they make a noticeable difference in operational costs.

Can Muffle Furnaces Be Customized for Specific Industrial Applications?

Absolutely, muffle furnaces can be customized for specific industrial applications. I’ve seen manufacturers tailor features like temperature ranges, chamber sizes, and heating elements to meet unique needs. Whether you need precise temperature control, specialized insulation, or custom chamber dimensions, these furnaces are adaptable. I recommend working closely with manufacturers to specify your requirements, ensuring the furnace is optimized for your particular process and improves efficiency and safety.

What Maintenance Routines Ensure Optimal Furnace Performance?

I keep my muffles in top shape by following a strict maintenance routine. Regularly inspecting and cleaning the heating elements prevents buildup, like a chef cleaning a stove to maintain efficiency. I also monitor temperature controls and replace worn parts promptly. These habits ensure my furnace runs smoothly, much like a well-tuned instrument, reducing downtime and extending its lifespan. Consistent care is key to peak performance.

Are There Portable Muffle Furnace Options for Fieldwork?

Yes, there are portable muffle furnace options perfect for fieldwork. I recommend looking for lightweight, compact models with sturdy insulation and reliable temperature control. These furnaces often come with battery or portable power options, making them ideal for remote locations. Always make certain the portable furnace you choose has safety features and easy transportability, so you can perform your tasks efficiently without sacrificing precision or safety in the field.

Conclusion

So, as I’ve discovered, choosing the right muffle furnace really comes down to understanding your specific needs—whether it’s high temperatures, size, or features like PID control. It’s funny how a small detail, like the voltage or capacity, can make all the difference. I hope this guide helps you find the perfect match—sometimes, the best choice feels like it was meant to be. Happy heating!