If you’re looking for the top PCB milling machines for 2026, I’ve got you covered. I recommend considering options like the Carvera Air with its 4th axis, the versatile Genmitsu CNC 3018-PRO, and the durable RATTMMOTOR 3018-PRO. Also, the CNCTOPBAOS 1610 PRO offers compact power, while the RATTMMOTOR CNC1610-PRO combines reliability and accuracy. If you want to know what makes each of these machines stand out, there’s more to explore.

Key Takeaways

- The top desktop CNC options like Carvera Air and Genmitsu CNC 3018-PRO offer compact, user-friendly PCB milling solutions suitable for various projects.

- Key selection factors include precision, material compatibility, control system features, size, and ease of assembly for optimal workflow.

- Compatibility with materials such as copper, FR4, plastics, and soft metals ensures versatility in PCB fabrication.

- Advanced control features like auto-probing, safety stops, and offline operation enhance accuracy and operational security.

- Machine size and workspace influence project capacity, with smaller models ideal for limited spaces and larger ones for bigger PCBs.

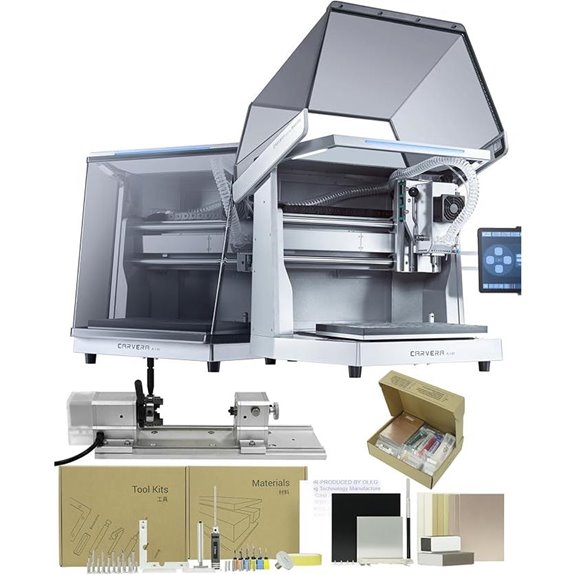

| Carvera Air Desktop CNC Machine with 4th Axis |  | Most Versatile | Control System: WiFi/USB with all-in-one CAM software | Spindle Speed: 0–13,000 RPM | Material Compatibility: Wood, plastics, metals | VIEW LATEST PRICE | See Our Full Breakdown |

| Genmitsu CNC 3018-PRO Router Kit with Offline Control |  | Beginner Friendly | Control System: Grbl (Arduino-based) software | Spindle Speed: 20,000 RPM | Material Compatibility: Plastics, soft metals, woods, PCB | VIEW LATEST PRICE | See Our Full Breakdown |

| RATTMMOTOR 3018-PRO CNC Router Kit with Controller |  | Compact Power | Control System: GRBL 1.1 control board | Spindle Speed: 10,000 RPM | Material Compatibility: Wood, plastic, PCB, soft metals | VIEW LATEST PRICE | See Our Full Breakdown |

| CNCTOPBAOS 1610 PRO CNC Milling Machine Kit |  | Professional-Grade | Control System: GRBL 1.1f control board | Spindle Speed: 20,000 RPM | Material Compatibility: Plastics, wood, soft metals | VIEW LATEST PRICE | See Our Full Breakdown |

| RATTMMOTOR CNC1610-PRO 3-Axis CNC Engraving Machine |  | Easy Setup | Control System: GRBL (USB connection) software | Spindle Speed: 10,000 RPM | Material Compatibility: Wood, plastic, PCB, soft metals | VIEW LATEST PRICE | See Our Full Breakdown |

More Details on Our Top Picks

Carvera Air Desktop CNC Machine with 4th Axis

If you’re looking for a versatile and precise PCB milling machine suitable for hobbyists or small-scale professionals, the Carvera Air Desktop CNC Machine with 4th Axis is an excellent choice. It offers accurate milling, carving, and engraving across various materials like wood, plastics, and metals. Its compact, enclosed design is user-friendly, with software compatible across multiple operating systems. The quick tool changer and auto-probing streamline workflows, while optional laser support adds flexibility. The 4th axis expansion allows for complex 3D shapes and cylindrical machining, making it ideal for detailed, advanced projects. Overall, it combines precision, automation, and versatility in one compact package.

- Control System:WiFi/USB with all-in-one CAM software

- Spindle Speed:0–13,000 RPM

- Material Compatibility:Wood, plastics, metals

- Work Area:3.6″ diameter x 7.9″ length

- Offline Operation:Yes (WiFi/USB control)

- Ease of Assembly:Compact, pre-assembled optional 4th axis

- Additional Feature:Supports 4th-axis rotation

- Additional Feature:Quick tool changer (10 seconds)

- Additional Feature:Wide material support range

Genmitsu CNC 3018-PRO Router Kit with Offline Control

The Genmitsu CNC 3018-PRO Router Kit with Offline Control is an excellent choice for hobbyists and small-scale professionals seeking a reliable, easy-to-use PCB milling machine. Its upgraded design features pre-assembled components, making setup quicker and more precise. The increased base height of 4cm improves stability, allowing for accurate carving across various materials like plastics, soft aluminum, woods, and PCBs. With a 300 x 180 x 45mm working area, it’s versatile for small to medium projects. Powered by a dependable Grbl control system and supported by open-source software, it’s a straightforward, expandable solution for PCB and prototyping needs.

- Control System:Grbl (Arduino-based) software

- Spindle Speed:20,000 RPM

- Material Compatibility:Plastics, soft metals, woods, PCB

- Work Area:300 x 180 x 45 mm

- Offline Operation:Yes (SD/TF card support)

- Ease of Assembly:Pre-assembled base, easy setup

- Additional Feature:Compatible with Carveco Maker Cam

- Additional Feature:Expandable to 3040 size

- Additional Feature:Pre-assembled components for ease

RATTMMOTOR 3018-PRO CNC Router Kit with Controller

For hobbyists and beginners seeking an easy-to-assemble CNC router, the RATTMMOTOR 3018-PRO with Controller offers a compact design and user-friendly features that make it ideal. Its aluminum alloy frame measures just 42x35x27cm with an 18x10x4.5cm working area, perfect for small projects. Equipped with a 12-24V spindle motor running at 10,000 RPM and a 42-stepper motor, it handles materials like wood, plastic, PCB, and soft metals. Assembly is straightforward, thanks to clear instructions and an included USB drive. The upgraded GRBL 1.1 control system supports offline operation via SD/TF cards, making it versatile and easy to use.

- Control System:GRBL 1.1 control board

- Spindle Speed:10,000 RPM

- Material Compatibility:Wood, plastic, PCB, soft metals

- Work Area:18 x 10 x 4.5 cm

- Offline Operation:Yes (SD/TF card, offline control)

- Ease of Assembly:Simple assembly, detailed manual

- Additional Feature:Offline SD/TF card operation

- Additional Feature:Silent fan cooling system

- Additional Feature:Compatible with multiple software

CNCTOPBAOS 1610 PRO CNC Milling Machine Kit

Designed with DIY enthusiasts and small-scale creators in mind, the CNCTOPBAOS 1610 PRO CNC Milling Machine Kit offers an upgraded and user-friendly experience. Its compact desktop design measures 11.81×10.23×9.84 inches, with a working area of 7.08×3.93×1.77 inches, perfect for engraving, carving, and cutting. It features a GRBL1.1f control board with an offline SD card reader, allowing operation without a PC. The spindle spins up to 20,000 rpm, supporting soft metals, plastics, and wood. Its NEMA17 stepper motors and manual axis adjustments make precise work easy, making it a versatile tool for DIY projects and small-scale manufacturing.

- Control System:GRBL 1.1f control board

- Spindle Speed:20,000 RPM

- Material Compatibility:Plastics, wood, soft metals

- Work Area:7.08 x 3.93 x 1.77 inches

- Offline Operation:Yes (SD card, offline control)

- Ease of Assembly:Compact design, manual adjustment

- Additional Feature:Manual axis adjustment

- Additional Feature:Emergency stop button included

- Additional Feature:Supports G-code, NC, TXT files

RATTMMOTOR CNC1610-PRO 3-Axis CNC Engraving Machine

If you’re a DIY enthusiast or beginner seeking an affordable, easy-to-assemble CNC engraving machine, the RATTMMOTOR CNC1610-PRO 3-Axis CNC Engraving Machine stands out. Its compact aluminum alloy frame measures 30x26x25cm, with an 18x10x4.5cm working area, making it perfect for small projects. It features a 775 spindle motor and a 42-stepper motor, supporting materials like wood, plastic, acrylic, PCB, and soft metals such as copper and aluminum. Easy to set up with a detailed manual, it connects via USB and supports software like GRBLcontrol and LaserGRBL, offering versatile engraving capabilities for hobbyists and beginners alike.

- Control System:GRBL (USB connection) software

- Spindle Speed:10,000 RPM

- Material Compatibility:Wood, plastic, PCB, soft metals

- Work Area:18 x 10 x 4.5 cm

- Offline Operation:Yes (USB, offline control support)

- Ease of Assembly:Easy assembly, detailed manual

- Additional Feature:Supports PWM spindle speed control

- Additional Feature:Includes detailed paper manual

- Additional Feature:Compatible with LaserGRBL software

Factors to Consider When Choosing PCB Milling Machines

When choosing a PCB milling machine, I focus on factors like precision and accuracy to guarantee detailed work. I also consider material compatibility and control system features to match my project needs. Finally, size, workspace, and ease of assembly influence how well the machine fits into my setup.

Precision and Accuracy

Choosing a PCB milling machine hinges on its ability to deliver high precision and accuracy. I look for machines with spindle runout under 0.01mm, ensuring detailed and accurate circuit traces. Positional accuracy, measured in micrometers, is vital for producing fine PCB features without errors. Auto-probing and leveling capabilities help maintain consistent milling depths, reducing mistakes. The rigidity and stability of the frame directly impact the machine’s ability to make clean, precise cuts and engravings. Additionally, the control system’s resolution, such as stepper motor steps per millimeter, influences overall accuracy. A combination of these factors guarantees high-quality, reliable milling results, especially when working on complex or miniature circuit boards. Prioritizing precision and accuracy is essential for professional-grade PCB manufacturing.

Material Compatibility

Material compatibility plays a critical role in selecting the right PCB milling machine, as different substrates and materials require specific handling. I look for a machine that can accurately engrave or cut common PCB materials like copper-clad boards, FR4, and phenolic substrates. Supporting soft metals such as aluminum or copper is essential for advanced designs. I also check if it can work with plastics like acrylic or PVC, often used in enclosures or insulation layers. Compatibility with insulating materials like fiberglass or other composite substrates is essential for multi-layer PCB fabrication. Additionally, I consider whether the machine can handle various cleaning or drilling materials necessary for complex PCB prototypes. Ensuring these capabilities helps me choose a versatile machine that meets my project needs.

Control System Features

The control system is a crucial factor that directly influences a PCB milling machine’s precision and ease of use. It determines how accurately the machine interprets G-code and commands, affecting overall performance. Features like emergency stops, limit switches, and probe ports boost safety and calibration precision. Compatibility with software such as GRBL, Mach3, or proprietary firmware impacts ease of operation and customization, making setup smoother. Support for offline control via SD card or USB allows continuous workflow without needing a computer connection, saving time. Additionally, the interface—whether USB, Ethernet, or wireless—affects data transfer speed and integration with design software. A dependable, versatile control system ensures precise milling, safety, and a seamless user experience.

Size and Workspace

When evaluating PCB milling machines, considering their size and workspace is essential because it directly impacts the types of projects you can handle. The size of the machine determines the maximum dimensions of your circuit boards, influencing whether you can manage small prototypes or larger, more complex designs. A bigger workspace allows for milling larger PCBs or multiple smaller boards at once, boosting productivity. However, if your workspace is limited, a compact machine might be more practical, though it could restrict design complexity. It’s important to check the machine’s specific dimensions—length, width, and height—to ensure they suit your typical PCB sizes. Matching the workspace to your needs helps avoid unnecessary adjustments or multiple setups, streamlining your workflow.

Ease of Assembly

Choosing a PCB milling machine that’s easy to assemble can save you time and frustration right from the start. Look for models that include clear, step-by-step instructions or manuals, so you know exactly what to do. Machines with pre-assembled components or modular, plug-and-play designs make setup much simpler, reducing the need for extensive DIY work. It’s also helpful if parts are clearly labeled and compatible with standard tools, minimizing errors and speeding up assembly. Additionally, check if the manufacturer offers online resources like video tutorials or responsive customer support—these can be lifesavers if you hit snags. Ultimately, a straightforward, well-documented assembly process allows you to start milling sooner and with less hassle.

Software Compatibility

Ensuring your PCB milling machine’s software is compatible with your operating system and design tools is vital for a smooth workflow. I recommend checking if the software supports Windows, Mac OS, Linux, or mobile platforms like iOS and Android, depending on your setup. Compatibility with popular CAD/CAM programs like Fusion360, SolidWorks, or VCarve Pro is also indispensable for seamless design integration. Additionally, verify if the machine offers dedicated or open-source control software such as GRBL, Candle, or Carveco Maker Cam, which guarantees reliable operation. It’s important that the software can handle G-code and relevant file formats needed for PCB milling. Finally, consider whether the software allows offline control via SD or TF cards, providing flexibility for working without a constant computer connection.

Frequently Asked Questions

What Safety Features Do These PCB Milling Machines Include?

These PCB milling machines include essential safety features like emergency stop buttons, dust collection systems, and safety shields to protect users. I always appreciate machines with automatic shut-off when safeguards are breached or if a malfunction occurs. Many also have grounding and insulation to prevent electrical hazards. Overall, these features give me confidence to operate safely while ensuring precision and efficiency in my projects.

How Easy Is It to Upgrade or Customize These Machines?

You’ll find that upgrading or customizing these machines is surprisingly straightforward. I’ve personally tinkered with them, and their modular design makes it easy to swap out parts or add new features. The open-source firmware and detailed documentation encourage customization, so whether you want better precision or new tools, you can usually tailor the machine to fit your needs. It’s almost like giving your equipment a personal touch.

What Is the Typical Maintenance Required for These Models?

Maintenance for these models usually involves regular cleaning of the spindle and work area to prevent dust buildup. I check and calibrate the machine periodically to ensure precision, and I lubricate moving parts as recommended by the manufacturer. Additionally, I inspect the belts and motors for wear and tear. Following these steps keeps my PCB milling machine running smoothly and extends its lifespan, saving me time and money in the long run.

Are Spare Parts Readily Available for These Machines?

Yes, spare parts are generally readily available for these machines, especially from reputable manufacturers. I’ve found that most suppliers keep essential components in stock or can ship quickly if needed. This makes maintenance less stressful and helps me keep my workflow smooth. I recommend purchasing from trusted brands or authorized dealers to guarantee compatibility and quick access to parts whenever necessary.

How Energy-Efficient Are These PCB Milling Machines?

These PCB milling machines are insanely energy-efficient—I swear, they use less power than a tiny LED! I’ve seen them run all day without skyrocketing the electricity bill. Thanks to smart design and power-saving features, they cut down energy consumption markedly. If you’re concerned about saving energy and reducing costs, these machines are a game-changer, making your workflow greener and more economical without sacrificing performance.

Conclusion

In wrapping up, I hope my insights help you select the superb, sturdy, and suitable PCB milling machine for your projects. With a focus on factors like functionality, flexibility, and finesse, you’ll find the perfect fit. Remember, choosing the right machine isn’t just about specs but about sparking your creativity and simplifying your soldering. So, step confidently into your next project and let your PCB pursuits prosper with the perfect machine in hand!