If you’re looking for the 12 best five-axis CNC mills for labs in 2025, I recommend considering models with high precision, robust build quality, and versatile features like multi-axis capabilities. Machines like the Cnc Router Machine 4040, FoxAlien Masuter series, and advanced multi-axis systems are designed for detailed research, prototyping, and complex manufacturing. These options support various materials and upgrade possibilities. Keep exploring to discover which models match your lab’s specific needs and aspirations.

Key Takeaways

- Five-axis CNC mills offer enhanced precision and complex geometries for advanced lab research and manufacturing applications.

- The latest models feature modular designs, high spindle power, and expanded work areas for versatile material processing.

- Upgraded automation, robust control systems, and compatibility with CAD/CAM software optimize workflow and accuracy.

- Modern five-axis mills include reliable, all-metal frameworks with linear guides and ball screws for added stability.

- Future-proof features like expandability, open-source firmware support, and multi-material capabilities ensure long-term lab utility.

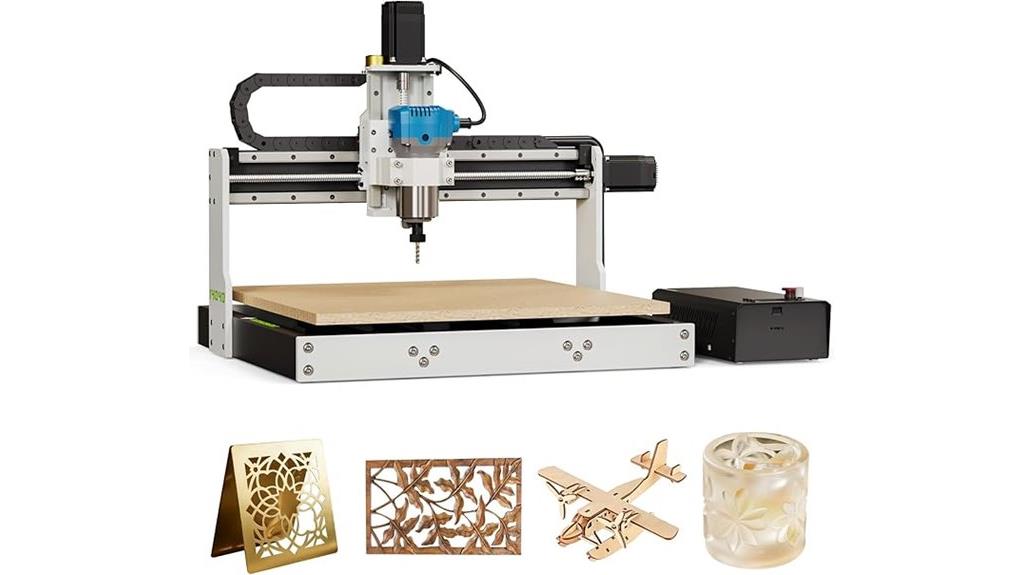

Cnc Router Machine 4040, Custom-Made 710W Milling Engraving Machine

If you’re looking for a compact yet powerful CNC milling and engraving machine suitable for detailed work, the Cnc Router Machine 4040 with a custom-made 710W spindle stands out. It features linear rails and ball screws on all axes, ensuring stability, efficiency, and high precision during operation. With a sizable working area of 15.75 x 15.75 x 3.74 inches, it’s perfect for intricate projects. Its modular, pre-assembled design allows setup in just 20 minutes. Powered by a robust 710W spindle and NEMA 23 motors, it delivers precise engraving and cutting across various materials, making it an excellent choice for both hobbyists and professionals.

Best For: hobbyists and professionals seeking a compact, high-precision CNC milling and engraving machine capable of detailed work on various materials.

Pros:

- High precision with a repeatable positioning accuracy of ±0.005mm.

- Easy setup with a modular, pre-assembled design that installs in just 20 minutes.

- Versatile control options including offline controller, PC application, and manual operation, plus expandability for MPG and laser functions.

Cons:

- Limited working area of 15.75 x 15.75 x 3.74 inches may restrict larger projects.

- The machine’s weight (29kg) could pose portability challenges.

- Requires familiarity with open-source software and hardware configurations for optimal customization.

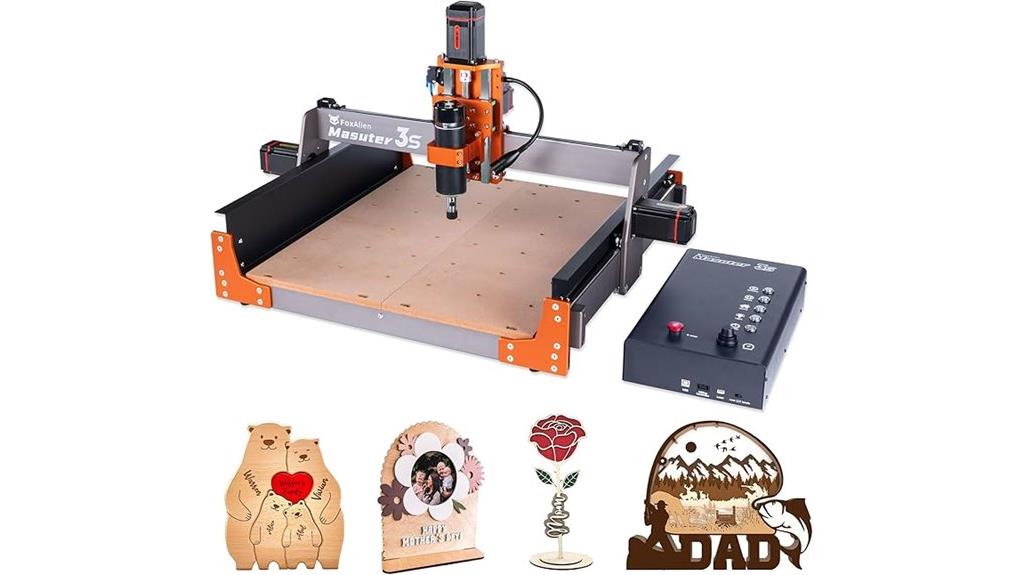

FoxAlien Masuter 3S CNC Router Machine

The FoxAlien Masuter 3S CNC Router Machine stands out as an excellent choice for hobbyists and small-scale professionals seeking a reliable, versatile CNC solution. Its sturdy build features 2360mm extrusions, dual HG-15 linear rails on the Z-axis, a T12 lead screw, and steel pulley systems, ensuring stability and smooth operation. With a generous work area of 15.75” x 15.75” x 3.74” and optional extensions, it handles various projects. Powered by NEMA23-76 stepper motors and a 400W spindle, it offers precise engraving and cutting of soft metals like aluminum. Its user-friendly controls, quick assembly, and strong community support make it a top pick for detailed craftsmanship.

Best For: hobbyists and small-scale professionals seeking a reliable, versatile CNC router for engraving, milling, and soft metal work.

Pros:

- Robust construction with high-quality materials ensuring stability and durability

- Precise engraving with an accuracy of 0.05mm and capable of cutting soft metals like aluminum

- User-friendly assembly and excellent community support for troubleshooting and upgrades

Cons:

- Limited work area of 15.75” x 15.75” x 3.74” may restrict larger projects

- Assembly time of 30-40 minutes could be challenging for beginners without guidance

- Some users report the need for modifications or upgrades to electronics and accessories for optimal performance

FASTTOBUY 3-Axis Digital Readout for CNC Machines

For those seeking precise position monitoring on milling and drilling machines, the FASTTOBUY 3-Axis Digital Readout stands out with its 5μm resolution and ±5μm accuracy. It features high-quality linear encoders, bright HD nixie tube displays, and supports multiple measurement functions. Designed for various machines like mills, lathes, and grinders, it enhances measurement accuracy and control. Installation can be complex, often requiring custom fabrication, but customer support is responsive. Users praise its reliability and value, often surpassing native machine precision. While setup may pose challenges, the modular design and detailed kit make it a versatile choice for precise, adaptable CNC measurement.

Best For: hobbyist and professional machinists seeking highly accurate, customizable digital readouts for milling, drilling, and grinding machines to improve measurement precision and control.

Pros:

- High resolution (5μm) and excellent accuracy (±5μm) for precise measurements

- Modular design allows for replacement and customization of parts

- Bright, HD nixie tube display provides clear and easy-to-read measurements

Cons:

- Installation can be complex and may require custom fabrication of brackets and hardware

- Some users experience issues with scale reliability and hardware quality

- Setup instructions are basic; additional tutorials may be necessary for optimal installation

FoxAlien Masuter Pro CNC Router Machine for Hobby Engraving

Designed with hobbyists in mind, the FoxAlien Masuter Pro CNC Router offers a user-friendly experience without sacrificing precision. Its all-metal framework, including a linear rail Z-axis, guarantees stability and durability for detailed engraving on materials like wood, acrylic, and nylon. The machine features two spindle clamps compatible with 60W and 300W spindles, plus support for custom upgrades such as a 65mm router or 1.5KW spindle. The upgraded dust-proof controller with accessible emergency stop boosts safety and convenience. Pre-assembled components and a detailed manual allow setup within 15 minutes. Its large work area and optional Y-axis extension make it versatile for various hobby projects.

Best For: hobbyists and DIY enthusiasts seeking a beginner-friendly, durable CNC router for detailed engraving and small-scale projects.

Pros:

- All-metal framework and linear rail Z-axis for enhanced stability and precision

- Easy setup with pre-assembled components and detailed manual, taking only 10-15 minutes

- Supports multiple spindle options and custom upgrades for versatile project capabilities

Cons:

- Limited work area without the optional Y-axis extension kit

- May require additional investment for certain upgrades like the 69mm spindle clamp

- Not designed for industrial-scale manufacturing or heavy-duty professional use

FoxAlien CNC Router Machine Masuter 3 with Steel Wheels

If you’re seeking a compact CNC router that combines durability with high precision, the FoxAlien CNC Router Machine Masuter 3 with Steel Wheels stands out as an excellent choice. Its sturdy frame features 23*60mm profiles for the X-axis and an 8mm aluminum sheet for the Y-axis, enhancing rigidity. The linear rails and lead screw on the Z-axis improve stability and accuracy. With a working area of 15.75” x 15.75” x 3.74”, it can handle thicker materials. Upgraded steel wheels on the X and Y axes boost precision, stability, and lifespan. Plus, the T-slot spoilboard and dust baffles make it versatile and easy to maintain.

Best For: hobbyists and small workshop owners seeking a durable, high-precision CNC router for woodworking, acrylic, and soft materials.

Pros:

- Sturdy frame with 23*60mm profiles and aluminum sheet for enhanced rigidity and stability

- Upgraded steel wheels on X and Y axes improve accuracy, durability, and lifespan

- Compact design with versatile work surface and optional extension kit for larger projects

Cons:

- Regular cleaning of steel wheels required for optimal performance

- Limited Z-axis travel of 3.74” may restrict thicker material processing without extension kit

- Coming soon Nema 23 stepper motor upgrade may require additional setup or investment

FoxAlien CNC Router Machine XE-PRO with Ball Screws

The FoxAlien CNC Router Machine XE-PRO with Ball Screws stands out as an excellent choice for hobbyists and small labs seeking a versatile, upgradeable, and precise CNC router. Its durable aluminum build, 400W spindle, and ball screw-driven XYZ axes ensure accurate cuts and carvings. Equipped with four NEMA23 closed-loop motors, it operates smoothly and quietly at speeds up to 5000mm/min, over 2.5 times faster than open-loop systems. The dual linear rails on the Z-axis boost rigidity, while the upgradeable structure allows adding linear rails on XY axes, transforming it into an industrial-grade machine. Quick to assemble, it’s perfect for both beginners and experienced users.

Best For: hobbyists and small labs seeking a versatile, upgradeable, and precise CNC router for woodworking, engraving, and light metalwork.

Pros:

- Durable aluminum construction with high-quality components for stability and longevity

- Fast, smooth operation with 5000mm/min maximum speed and quiet closed-loop motors

- Upgradeable design allowing addition of linear rails on XY axes for industrial-grade performance

Cons:

- Requires external design software, as it does not include built-in CAD or design programs

- Some hardware and control board reliability issues reported, especially with used or poorly assembled units

- Limited standard features for spindle upgrades or additional axes without modifications

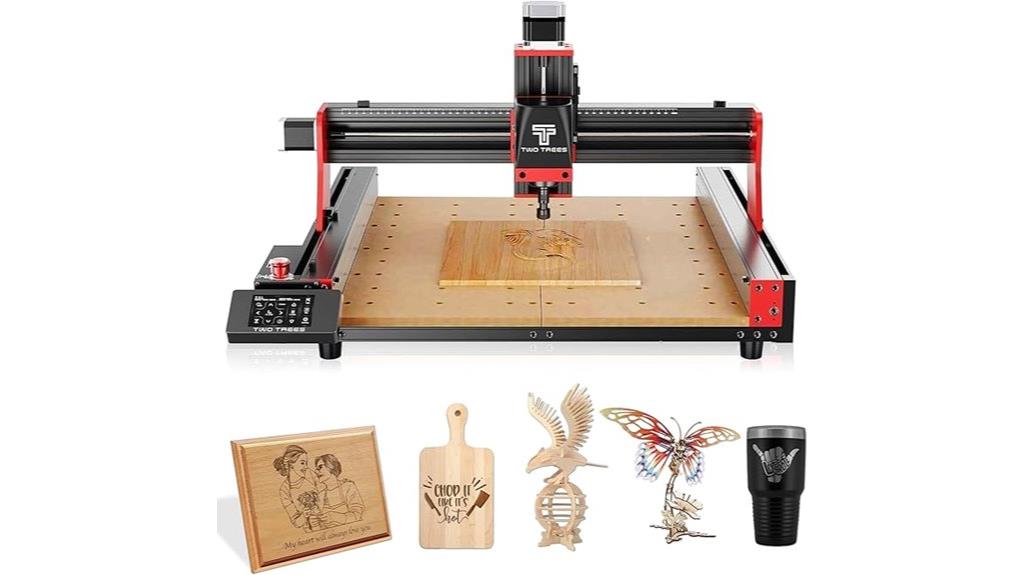

Twotrees CNC Router Machine TTC450 Pro for Woodworking

For hobbyists and small labs seeking precise woodworking capabilities, the Twotrees CNC Router Machine TTC450 Pro stands out with its dual NEMA 42 stepper motors on the Y-axis, delivering exceptional torque and accuracy. Its all-metal construction and 18.1″ x 18.1″ x 3.1″ working area support various materials like wood, acrylic, and MDF with high precision. The machine is lightweight yet durable, compatible with popular software like Fusion360 and Artcam, and easy to assemble within 30 minutes. Its upgraded spindle clamp supports multiple kits, including laser modules, making it versatile. Safety features and straightforward calibration guarantee reliable, long-lasting performance for hobbyists and small-scale projects.

Best For: hobbyists and small labs seeking precise and versatile woodworking, engraving, and carving capabilities with easy assembly and reliable performance.

Pros:

- Dual NEMA 42 stepper motors on the Y-axis provide exceptional torque and accuracy.

- All-metal construction with a generous 18.1″ x 18.1″ x 3.1″ working area supports various materials.

- Compatible with popular software like Fusion360, Artcam, and easy to assemble within 30 minutes.

Cons:

- Weighs 48 pounds, which may be less portable for some users.

- Limited maximum working height (3.1 inches), not suitable for very thick materials.

- Requires a compatible power source and some familiarity with CNC setup for optimal use.

CNC Router Machine 6060 with 710W Power and 3-Axis Engraving

The CNC Router Machine 6060 stands out for labs that require precise and versatile engraving, thanks to its 23.6 x 23.6 x 3.74-inch working area and robust construction. Its sturdy build minimizes vibrations, ensuring stability during detailed work on wood, MDF, acrylic, aluminum, leather, or metals. Powered by a 710W router and a 42mm NEMA 17 stepper motor, it offers speeds up to 30,000 RPM and maximum X/Y speeds of 3,500 mm/min. The open-source Grbl v1.1 control system supports expansion, while the modular design allows quick setup within 20 minutes. It’s ideal for high-precision engraving and versatile lab applications.

Best For: laboratories and workshops seeking precise, versatile engraving and cutting solutions for materials like wood, acrylic, aluminum, and metals.

Pros:

- Robust construction minimizes vibrations, ensuring high stability and precision during detailed engraving.

- Large working area (23.6 x 23.6 x 3.74 inches) accommodates various project sizes.

- Open-source Grbl v1.1 control system with expansion options supports customization and future upgrades.

Cons:

- Installation, while quick, may require technical knowledge for optimal setup and expansion.

- Max speeds (3,500 mm/min X/Y and 500 mm/min Z) may be limiting for very high-speed production.

- Replacement of stepper motors necessitates drive chip swaps, which can be complex for some users.

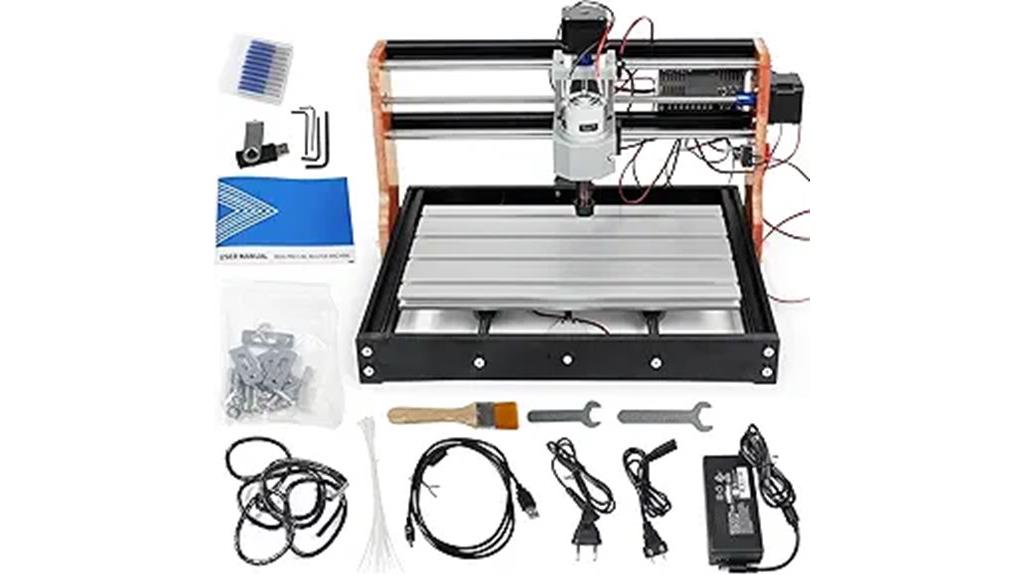

RATTMMOTOR CNC1610-PRO 3 Axis DIY CNC Router Machine Kit

If you’re seeking an affordable, entry-level CNC router perfect for DIY projects and small-scale engraving, the RATTMMOTOR CNC1610-PRO 3 Axis DIY CNC Router Machine Kit stands out. Made from aluminum alloy, it’s compact with a 30x26x25cm frame and an 18x10x4.5cm working area, ideal for engraving materials like wood, plastic, acrylic, and aluminum. It features a 775 spindle motor that reaches 10,000 RPM and 42 stepper motors for precise movement. Easy to assemble with included manuals, it connects via USB to Windows-based software. While perfect for beginners, users report some challenges with software usability and limited support, especially on Mac systems.

Best For: DIY enthusiasts and beginners seeking an affordable, compact CNC router for small-scale engraving and milling projects on soft materials.

Pros:

- Easy to assemble with included manuals, suitable for beginners

- Made from durable aluminum alloy with a compact, portable design

- Supports precise engraving on wood, plastic, and aluminum with a 10,000 RPM spindle

Cons:

- Software usability can be challenging, especially on Mac systems

- Limited customer support and documentation quality reported by users

- Not suitable for hard metals, glass, or larger industrial projects

RATTMMOTOR 3018-PRO CNC Wood Router Machine Kit

Looking for an accessible yet capable CNC machine to kickstart small projects? The RATTMMOTOR 3018-PRO CNC Wood Router Machine Kit fits the bill. Its lightweight aluminum alloy frame and stainless steel screw rods guarantee durability and stability, even during longer sessions. It supports engraving on wood, plastic, acrylic, and aluminum, making it versatile for DIY makers and educators. Features like limit switches, an emergency stop button, and a silent cooling fan enhance safety and usability. While setup can be challenging for beginners due to software issues and limited support, with patience and upgrades, this machine offers a solid starting point for small-scale craftsmanship.

Best For: DIY enthusiasts and educators seeking an affordable, beginner-friendly CNC machine for small projects and practice.

Pros:

- Lightweight and durable aluminum alloy frame ensures stability and portability

- Supports engraving on various materials including wood, plastic, and aluminum

- Equipped with safety features like limit switches and emergency stop button

Cons:

- Setup can be complicated due to software compatibility issues and limited support

- Missing hardware parts such as nuts and bolts may require additional purchase

- Some users experience hardware problems like slipping shafts and motor RPM loss over time

VEVOR CNC Router Machine, 300W, 3 Axis

Designed for versatility and precision, the VEVOR CNC Router Machine with 300W power and 3-axis control is ideal for hobbyists and small-scale professionals seeking an accessible yet capable milling solution. Its large working area of 15.74 x 15.7 x 2.95 inches allows for diverse projects, from engraving wood and acrylic to cutting foam and vinyl. Made from durable aluminum alloy, it offers stability and shock absorption. The machine features a user-friendly 2.4-inch touchscreen controller, enabling independent operation without a computer. While it requires CNC programming knowledge, it’s perfect for those looking for a reliable, versatile tool for artistic and industrial applications.

Best For: hobbyists and small-scale professionals seeking a versatile, easy-to-operate CNC router for engraving and milling a variety of materials.

Pros:

- Large working area of 15.74 x 15.7 x 2.95 inches suitable for diverse projects

- Independent operation with a user-friendly 2.4-inch touchscreen controller

- Constructed from durable aluminum alloy offering stability and shock absorption

Cons:

- Requires prior knowledge of CNC programming and software for operation

- Not suitable for high-hardness materials or deep cuts that may cause deviations or overheating

- Assembly involves multiple parts and connections, which may be time-consuming for some users

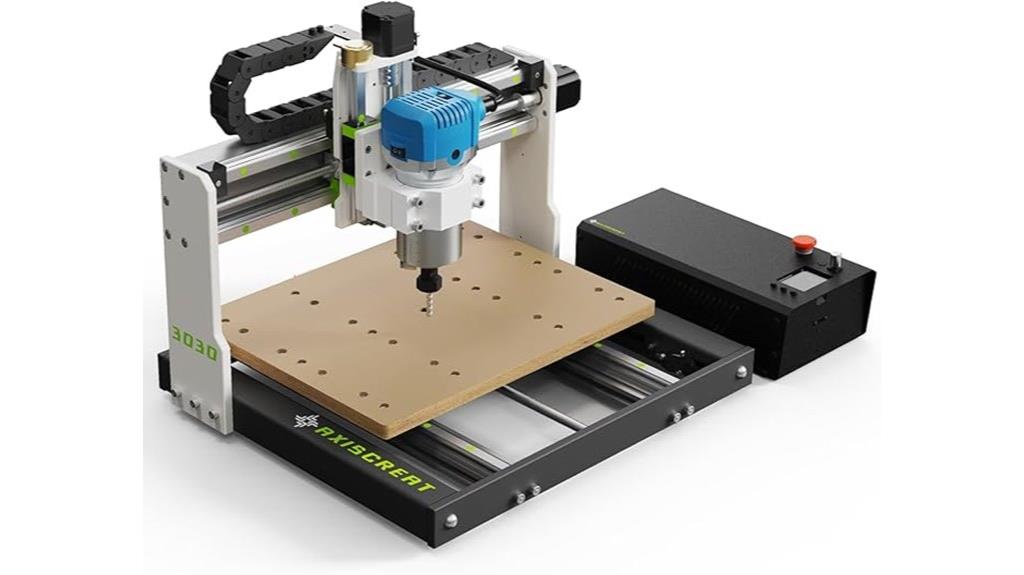

CNC Router Machine 3030 for Wood, Acrylic, Aluminum

The CNC Router Machine 3030 stands out as an ideal choice for small labs and workshops that require precise and versatile engraving on wood, acrylic, and aluminum. It features a powerful 710W trimmer router, linear guides, and leadscrew drives for accurate movement. With a compact 11.8 x 11.8 x 3.74-inch workspace, it supports high-speed engraving across various materials. The machine’s solid structure minimizes vibration, ensuring consistent results. Easy to set up—just unpack, connect, and install software—it uses open-source Grbl firmware and offers multiple control options, making it perfect for detailed milling, engraving, and drilling projects.

Best For: small labs and workshops seeking precise, versatile engraving and milling on wood, acrylic, and aluminum with easy setup and multiple control options.

Pros:

- Compact size with a working area of 11.8 x 11.8 x 3.74 inches, ideal for small spaces

- Supports a wide range of materials including wood, acrylic, aluminum, leather, and metals

- Easy to operate with minimal setup—just unpack, connect, and install software

Cons:

- Limited workspace size may restrict larger projects

- Requires replacing the driver chip when upgrading stepper motors

- Does not include built-in laser capabilities, only expansion options for laser output

Factors to Consider When Choosing Five‑Axis CNC Mills for Labs

When selecting a five-axis CNC mill for a lab, I focus on key factors like precision, workspace size, and reliability to guarantee it meets our project needs. Compatibility with control software and material versatility are also essential for seamless operation and flexibility. Considering these points helps me choose a machine that’s efficient, accurate, and versatile for various applications.

Precision and Accuracy

Achieving high precision and accuracy with five-axis CNC mills is essential for producing complex, detailed parts in lab settings. These machines typically reach repeatable positioning accuracies of ±0.005 millimeters or better, guaranteeing tight tolerances. The use of ball screws and linear guides on all axes enhances movement precision and minimizes backlash, which is critical for intricate machining. Advanced control systems equipped with high-resolution encoders and feedback loops enable real-time position corrections, maintaining accuracy throughout operations. Proper calibration and regular maintenance of the machine’s axes are indispensable to sustain ideal precision over time. Given the complexity of five-axis kinematics, rigorous software and hardware synchronization is needed to ensure accurate multi-directional movements, especially for detailed, multi-faceted parts.

Workspace Size

Choosing the right workspace size for a five-axis CNC mill is essential because it directly impacts your ability to handle your projects efficiently. The workspace determines the maximum size of parts you can machine in a single setup, influencing project scope and complexity. Larger work areas, like 24″ x 24″ x 12″, allow for bigger components or multiple smaller parts at once, boosting productivity. Smaller workspaces, such as 12″ x 12″ x 8″, are ideal for detailed, high-precision work on smaller parts but may require repositioning for larger projects. It’s important to match the machine’s workspace with your typical material sizes to minimize re-fixturing. Additionally, ensure there’s enough clearance for tool changes and accessories to avoid obstructions during operation.

Machine Reliability

The reliability of a five-axis CNC mill hinges on the quality of its key components, such as high-precision ball screws and linear rails, which guarantee consistent performance over time. A sturdy frame design also plays a vital role by minimizing vibrations and mechanical wear, helping prevent breakdowns and guaranteeing accuracy during extended operations. The stability and durability of the spindle and drive motors directly impact uptime and reduce maintenance needs. Additionally, advanced control systems with built-in fault detection and error correction capabilities help prevent unexpected shutdowns, keeping the machine running smoothly. Regular maintenance, including lubrication and calibration, is essential to preserve dependability and extend the machine’s lifespan. Choosing a CNC mill with these reliability features ensures consistent results and reduces downtime in a lab setting.

Control Software Compatibility

Reliable operation of a five-axis CNC mill depends not only on sturdy hardware but also on compatible control software. To guarantee smooth operation, I recommend verifying that the software works seamlessly with your operating system, whether Windows, macOS, or Linux. It’s also essential to confirm that it supports the file formats and G-code standards your lab uses regularly. Integration with popular CAD/CAM programs can considerably streamline your design-to-production workflow, saving time and reducing errors. Additionally, look for software that offers remote monitoring, automation, and expansion capabilities to future-proof your setup. Finally, review user feedback and support options, as dependable technical assistance is critical for troubleshooting and long-term operation. Confirming software compatibility is key to maximizing your CNC mill’s performance.

Material Versatility

Since lab research often involves working with diverse materials, selecting a five-axis CNC mill that can handle multiple types is vital. These machines process metals, plastics, composites, and ceramics, providing the flexibility needed for varied projects. The ability to perform complex geometries and contouring on different materials enhances a lab’s capabilities. Material compatibility depends on spindle power and tooling options, which determine the thicknesses and types that can be machined effectively. Multi-material capability requires support for different tools, like high-speed drills, engravers, or heavy-duty cutters. Flexibility to switch between materials without extensive reconfiguration is essential, especially when multiple projects demand different material processing. This versatility ensures your lab can adapt quickly and efficiently to evolving research needs.

Ease of Maintenance

Choosing a five-axis CNC mill for a lab means considering how easy it is to maintain over time. I look for machines with modular components and accessible parts, which make routine maintenance and repairs straightforward. Automated lubrication systems are a big plus—they reduce manual effort and help keep the machine running smoothly. Clear, thorough maintenance manuals and diagnostic tools are essential for quick troubleshooting, minimizing downtime. I also prioritize models with durable spindle bearings and high-quality drive belts that don’t need frequent replacement. Additionally, the design should allow easy access to critical components like electronics, motors, and tool changers. This accessibility ensures maintenance tasks are efficient, keeping the machine in prime condition without excessive effort or delays.

Upgradability Options

When selecting a five-axis CNC mill for a lab, it’s important to contemplate how easily the machine can be upgraded to meet future needs. I look for models that support modular upgrades, like adding axes or enhancing spindles, so I can adapt as project requirements evolve. Compatibility with open-source firmware such as Grbl or LinuxCNC is a plus, enabling custom hardware integrations down the line. I also check if the control system allows for upgrades with higher precision components, like ball screws or linear guides, to improve accuracy over time. Availability of upgrade kits for parts like stepper motors, spindles, or tool changers is essential for boosting performance. Ultimately, I favor designs that permit straightforward hardware and software modifications without extensive disassembly, ensuring continuous improvement.

Cost and Budget

Budget plays a crucial role in selecting a five-axis CNC mill for a lab, as prices can vary widely from around $10,000 for basic models to over $100,000 for high-end, industrial-grade machines. Your budget will influence key features like working volume, spindle power, and control systems, which directly impact performance and capabilities. Lower-cost CNC mills often lack stability, accuracy, or durability, potentially affecting long-term precision and lifespan. Remember to factor in additional expenses such as installation, maintenance, tooling, and software costs. Sometimes, investing a bit more upfront in a machine with higher-quality components can save money over time by providing better reliability and reduced operational costs. Balancing initial investment with long-term value is essential when considering your lab’s specific needs.

Frequently Asked Questions

What Maintenance Routines Ensure Optimal Five-Axis CNC Mill Performance?

To keep my five-axis CNC mill running smoothly, I perform daily checks on lubrication and coolant levels, ensuring they’re topped up. I clean the machine regularly to prevent dust and debris buildup, and I inspect tools and parts for wear and tear. Monthly, I calibrate the axes and check for alignment issues. Consistent maintenance like this minimizes downtime and keeps my mill operating at peak performance.

How Do Different Spindle Types Impact Machining Accuracy and Versatility?

They say, “You are only as good as your tools,” and I believe that applies to spindle types. Different spindles, like belt-driven or direct-drive, markedly impact accuracy and versatility. Belt spindles offer speed and cost benefits, while direct-drive spindles provide higher precision and torque. Choosing the right spindle depends on your specific machining needs, helping you achieve ideal results with greater flexibility and accuracy.

What Software Features Are Essential for Five-Axis CNC Programming?

When programming five-axis CNC machines, I look for software that offers intuitive 3D visualization, advanced toolpath strategies, and seamless simulation. These features help me catch errors early and optimize cuts for precision. I also value robust post-processing options and easy integration with CAD models, so I can streamline workflows. Overall, efficient, user-friendly software boosts my productivity and guarantees high-quality results every time.

How Does Machine Footprint Influence Lab Workspace Organization?

The machine footprint really shapes how I organize my lab workspace. Smaller footprints save space, letting me fit more equipment and improve workflow, while larger machines can be intimidating but offer more capacity. I’ve learned that balancing size with functionality is key. By choosing a CNC mill with an ideal footprint, I ensure efficient use of space without sacrificing performance, keeping my lab organized and productive.

What Safety Protocols Are Necessary for High-Precision Five-Axis CNC Operation?

When operating high-precision five-axis CNC mills, I always prioritize safety protocols. I make sure to wear appropriate PPE, including safety glasses and ear protection, and keep the workspace clean and free of clutter. I double-check safety interlocks and emergency stops before starting. Additionally, I stay alert and avoid distractions. Regular maintenance and proper training are essential to prevent accidents and guarantee safe, effective operation.

Conclusion

Choosing the right five-axis CNC mill is like balancing precision with power—both are vital, yet often seem at odds. Whether you’re after the intricate detail of the FoxAlien Masuter or the robust capabilities of the RATTMMOTOR 3018-PRO, remember that quality and adaptability matter most. In the end, it’s not just about the machine’s specs, but how it empowers your creativity and pushes your projects beyond limits. The perfect mill awaits your next breakthrough.