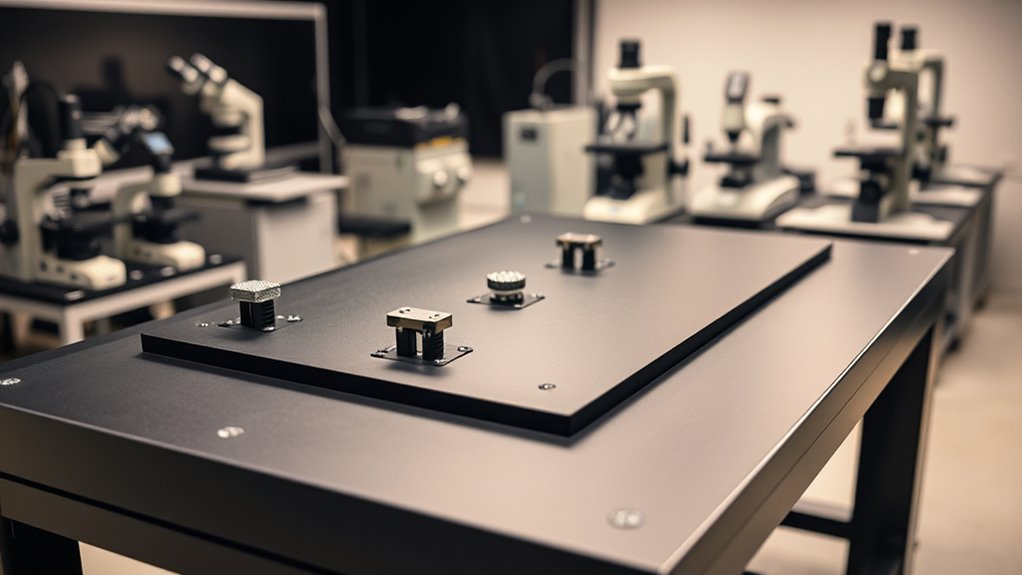

For optics requiring perfect precision, I recommend high-quality vibration isolation systems like heavy-duty springs, wall-mounted isolators, and specialized feet, which effectively dampen low-frequency vibrations. These options help stabilize sensitive equipment and improve image clarity. Materials like cast iron, rubber, and aluminum guarantee durability and long-term performance. If you want to explore the top 15 solutions that can keep your optics perfectly steady, there’s more to discover below.

Key Takeaways

- Choose heavy-duty cast iron or steel isolators with high load capacities for stable optical setups.

- Use specialized isolation feet with ceramic beads or high-density silicone to reduce vibrations on sensitive equipment.

- Opt for wall or ceiling-mounted isolators to minimize floor-borne vibrations affecting optical precision.

- Select vibration damping materials like rubber mounts and cork pads for effective low-frequency vibration absorption.

- Ensure proper installation and support to prevent equipment movement and maintain optimal optical alignment.

Heavy Duty Spring Vibration Isolator (ZD-3, 4-pack)

If you’re working with heavy machinery that requires reliable vibration control, the Heavy Duty Spring Vibration Isolator (ZD-3, 4-pack) is an excellent choice. I’ve found it to be highly effective at reducing vibrations and noise from equipment like pumps, fans, and air conditioners. Made from durable cast iron with a surface spray for longevity, it features quality spring groups that absorb shocks efficiently. The anti-slip pads keep everything steady during operation, preventing displacement. With a load capacity of up to 261 pounds, this set is versatile and easy to install, making it ideal for various heavy-duty applications.

Best For: professionals and technicians seeking reliable vibration isolation solutions for heavy machinery such as pumps, fans, and air conditioning units.

Pros:

- Made from durable cast iron with surface spray treatment for enhanced longevity

- Equipped with built-in spring groups for superior shock absorption and noise reduction

- Includes anti-slip pads to prevent slipping and ensure stability during operation

Cons:

- May require precise installation to maximize effectiveness

- Heavier weight due to cast iron construction could make handling more difficult

- Limited to load capacities up to 261 pounds, which may not suit exceptionally heavy equipment

Wall Mounted Spring Vibration Isolator

The Wall Mounted Spring Vibration Isolator stands out as an ideal choice for anyone seeking effective vibration control in environments like recording studios, home theaters, or industrial settings. Its side-mounted design with upgraded metal pressure plates and thicker damping rubber pads enhances shock absorption and sound insulation. Compact at 4.7 inches, it’s built with sturdy metal casing and a stable spring structure to support loads up to 110 lbs. Easy to install on walls or ceilings, it’s perfect for reducing vibrations in dust collectors, KTV rooms, or industrial equipment. Customers report significant noise reduction and vibration dampening, making it a reliable solution for maintaining quiet, precise environments.

Best For: individuals or professionals needing effective vibration and noise reduction in environments like recording studios, home theaters, industrial settings, and areas with heavy equipment.

Pros:

- Durable construction with sturdy metal casing and stable spring structure for long-term use

- Enhanced shock absorption and sound insulation due to upgraded metal pressure plates and thicker damping rubber pads

- Easy to install on walls or ceilings with recommended spacing for optimal vibration damping

Cons:

- May require precise spacing and installation to achieve maximum effectiveness

- Limited to supporting loads up to 110 lbs, which may not suit extremely heavy equipment

- Slightly larger size may be less suitable for very tight or compact spaces

Top Mounted Vibration Isolator Hanger

A top mounted vibration isolator hanger stands out as an ideal choice for those seeking to suspend heavy gear securely from ceilings while minimizing vibrations. Its upgraded design features metal pressure plates and thicker damping rubber pads, boosting shock absorption and sound insulation. With a sturdy metal casing and stable spring components, it supports loads up to 110 pounds, perfect for heavy equipment like subwoofers or AC units. Quick to install, usually within 10 minutes, it’s suitable for various environments such as studios, theaters, and homes. Users report noticeable noise reduction and improved sound quality, making it a reliable, long-term vibration control solution.

Best For: those looking to securely suspend heavy equipment like subwoofers, AC units, or sound systems from ceilings while effectively reducing vibrations and noise transmission.

Pros:

- Effective vibration reduction and sound insulation, especially for low bass and loud noises

- Quick and easy installation, typically within 10 minutes

- Durable construction with sturdy metal casing and stable spring components supporting loads up to 110 pounds

Cons:

- Some users may experience limitations when mounting extremely heavy equipment beyond the rated capacity

- Occasional issues with bent bolts indicating minor quality control concerns

- Potential need for careful load verification and inspection before installation

Preffair Turntable Anti-Vibration Isolation Feet (Aluminum Alloy)

Preffair Turntable Anti-Vibration Isolation Feet made from high-quality aluminum alloy are an excellent choice for audiophiles seeking to enhance their equipment’s sound clarity. These four sturdy feet support up to 350 lbs and feature ceramic beads inside for shock absorption. Their slim design makes installation easy under various audio gear, including turntables, speakers, and amplifiers. The rubber padding prevents slipping and surface damage, ensuring stability. By decoupling equipment from floor vibrations, they improve bass tightness, sound clarity, and spatial imaging. Overall, these isolation feet are a cost-effective way to reduce resonance and elevate your listening experience.

Best For: audiophiles and audio enthusiasts looking to improve sound clarity, bass response, and reduce vibrations for their turntables, speakers, and amplifiers.

Pros:

- Made of durable high-quality aluminum alloy with high hardness and density for effective vibration reduction

- Features ceramic beads inside for enhanced shock absorption and sound clarity

- Easy to install with slim profile and rubber padding for surface protection and slip prevention

Cons:

- May lack anti-slip pads on both sides in some models, requiring additional rubber discs for stability

- Not recommended for use with tube amplifiers due to potential vibration transfer through tubes

- Proper installation requires removing existing feet and ensuring level placement for optimal performance

Sound Addicted subPods Subwoofer Isolation Feet, 4PCs

Sound Addicted subPods Subwoofer Isolation Feet are an excellent choice for audiophiles and home theater enthusiasts seeking to enhance sound clarity and minimize vibrations. Made from high-density silicone and precision-engineered metal, they support up to 200 lbs, fitting various subwoofer sizes. Easy to install—just place them under each corner—they effectively decouple vibrations from floors, reducing noise transfer and muddiness. Users report noticeable improvements in sound quality, especially on hardwood floors, and fewer neighbor complaints. Durable and well-built, these feet protect flooring and keep equipment stable. Priced around $34, they offer great value for upgrading your audio setup’s vibration control.

Best For: audiophiles, home theater enthusiasts, and anyone looking to improve sound clarity and reduce vibrations from subwoofers and audio equipment.

Pros:

- Effective vibration reduction and sound clarity enhancement on various flooring types

- Durable construction with high-density silicone and sturdy metal, supporting up to 200 lbs

- Easy to install without adhesives, fitting all subwoofer sizes and other vibrating devices

Cons:

- Some users may find it challenging to place under certain larger or irregularly shaped subwoofers

- Slightly higher price point at around $34 compared to basic rubber feet

- Not a complete noise solution, requiring additional measures for total soundproofing

Sound Isolation Pads, Cork Pads for Turntables

If you’re looking to minimize vibrations and improve sound clarity for your turntable setup, cork pads are an excellent choice. These pads, measuring 2” x 2” x 7/8”, are designed to absorb floor vibrations, resonances, and acoustic feedback, resulting in clearer sound, tighter bass, and fewer skips. Easy to install without adhesives, they sit between your device and the surface, providing shock absorption and stability. Suitable for most HiFi components, especially on stable floors, users report noticeable improvements in sound quality and stability. Overall, cork pads are a simple, effective solution to enhance your turntable’s performance and protect your equipment from unwanted vibrations.

Best For: audiophiles and turntable enthusiasts seeking to reduce vibrations and enhance sound clarity for their audio setups.

Pros:

- Easy to install and reposition without adhesives for flexible use

- Effectively absorbs vibrations, resonances, and acoustic feedback

- Improves overall sound quality, bass response, and stability

Cons:

- Slightly smaller size may require multiple pads for larger or heavier equipment

- Some users may experience increased vibration loudness when tapping the table

- Not suitable for extremely spongy or uneven floors without additional support

Red Spring Vibration Isolators with Mounting Bolts

Red Spring Vibration Isolators with Mounting Bolts are an excellent choice for industrial environments where heavy machinery needs secure, effective vibration control. These isolators are built with durable steel plates coated in red powder, offering corrosion resistance, and high-quality rubber spring cushions for shock absorption. With adjustable leveling bolts, they ensure proper alignment and balance. Measuring roughly 6.29 inches in diameter and 3.34 inches high, they support various load capacities, making them versatile. Quick-install hardware allows for secure mounting to floors or foundations, reducing vibrations, enhancing stability, and protecting sensitive equipment in demanding industrial settings.

Best For: industrial facilities and heavy machinery operators seeking reliable vibration control and equipment stability.

Pros:

- Durable construction with corrosion-resistant steel and high-quality rubber cushions

- Adjustable leveling bolts for precise alignment and balance

- Easy to install with included mounting hardware for secure foundation attachment

Cons:

- Limited to specific load capacities; may not suit very light or extremely heavy machinery

- Compact size may require additional support for larger equipment

- Requires proper leveling during installation to ensure optimal performance

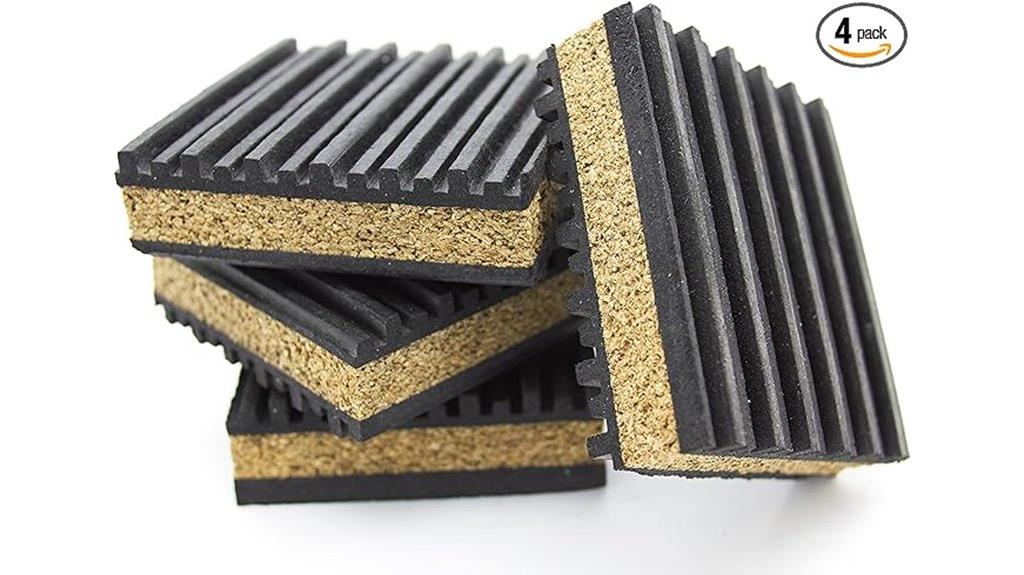

PneumaticPlus Anti Vibration Rubber & Cork Pads (Pack of 4)

The PneumaticPlus Anti Vibration Rubber & Cork Pads are an excellent choice for anyone seeking reliable vibration damping for delicate optical equipment. Each pad measures 3 x 3 x 7/8 inches and is made from durable rubber and cork, resisting aging, water, and oil. With a maximum load capacity of 50 PSI per pad, they effectively reduce vibrations and noise in indoor and outdoor settings. Suitable for supporting speakers, turntables, or machinery, they help minimize rattling and floor damage. Easy to install and doubleable for increased load, these pads offer a cost-effective, practical solution for maintaining stability and ensuring best performance of sensitive optics.

Best For: individuals needing effective vibration damping for delicate optical equipment, audio gear, or machinery to reduce noise and prevent floor damage.

Pros:

- Durable rubber and cork construction resist aging, water, and oil for long-lasting performance

- Effective in reducing vibrations and noise transmission in various settings

- Easy to install, with the option to double the pads for increased load capacity

Cons:

- Initial rubber odor may be strong and require airing out before use

- Size and price might be considered high relative to the quantity and application needs

- Not fully effective for highly sensitive environments or very heavy equipment

HiFi Speaker Stand Feet Pads for Audio Isolation (4PCS)

Designed for audiophiles seeking to enhance sound clarity, HiFi Speaker Stand Feet Pads for Audio Isolation (4PCS) provide an easy and effective way to minimize vibrations that can distort audio quality. Made of silicone, each 2-inch pad absorbs shocks and reduces resonance in speakers, turntables, amplifiers, and subwoofers. Their self-adhesive backing allows quick, secure installation, preventing equipment movement. By isolating your gear from external vibrations, these pads help prevent vinyl record skips, improve resonance control, and deliver cleaner sound. Compact and lightweight, they’re compatible with a wide range of audio devices, ensuring consistent, high-quality audio performance in any setup.

Best For: audiophiles and sound enthusiasts looking to improve audio clarity and reduce vibrations in their audio equipment setups.

Pros:

- Effective vibration and resonance reduction for clearer sound quality

- Easy to install with self-adhesive backing for secure placement

- Compatible with a wide range of audio devices including speakers, turntables, and subwoofers

Cons:

- Silicone material may attract dust or debris over time

- Limited to 2-inch diameter pads, may not fit larger or differently shaped equipment

- Adhesive backing might lose stickiness after prolonged use or exposure to dust

Sound Addicted Isolation Pads for Soundbar (4 Pack)

If you’re looking to improve your home audio setup, Sound Addicted Isolation Pads for Soundbar (4 Pack) offer an easy and effective way to reduce vibrations and enhance sound clarity. Made from high-density acoustic foam topped with EVA, these discreet pads absorb impact, prevent slipping, and stabilize your soundbar. They considerably reduce rattling, shaking, and resonance, resulting in clearer sound and better bass. Suitable for most soundbars up to 20 pounds, users report noticeable audio improvements and quieter environments. Installation is straightforward, and the small size keeps them almost invisible. Overall, these pads are a simple upgrade for a more natural, distortion-free listening experience.

Best For: Home entertainment enthusiasts seeking an easy, effective way to reduce vibrations and improve sound clarity for their soundbars and other audio equipment.

Pros:

- Easy to install and discreet, nearly invisible under the soundbar

- Significantly reduces vibrations, rattling, and resonance for clearer sound and better bass

- Compatible with most soundbars up to 20 pounds and versatile for use under turntables or speakers

Cons:

- May experience slipping or movement on certain soundbar models without additional mounting solutions

- Slight scattering or sliding when lifting the pads, requiring careful handling

- Limited to soundbars and equipment weighing up to 20 pounds, not suitable for heavier devices

NATGAI Ceiling Spring Vibration Isolator Hangers (4 Pack)

For anyone seeking a reliable solution to minimize vibration transfer in delicate optical setups, NATGAI Ceiling Spring Vibration Isolator Hangers (4 Pack) stand out due to their robust construction and high load capacity. Made from 3mm steel with high-grade springs and silicone, they provide excellent vibration absorption and stability. Measuring 100mm by 45mm by 50mm and supporting up to 50kg, they are suitable for various installation environments. Easy to install with a simple bolt hole, they’re ideal for ceilings, walls, or surfaces. Perfect for home theaters, studios, or optical labs, these isolators effectively reduce noise and vibration transfer.

Best For: DIY enthusiasts and professionals seeking a durable, high-capacity vibration isolator for ceilings, walls, or surfaces in home theaters, studios, or optical labs.

Pros:

- Made from premium 3mm steel with high-grade springs and silicone for excellent vibration absorption and stability

- Supports up to 50kg (110 lbs), suitable for various heavy equipment and delicate setups

- Simple installation with a bolt hole, requiring no complex tools or professional skills

Cons:

- Bolts are not included, so additional hardware purchase may be necessary for specific mounting needs

- Recommended spacing of 24 inches may require multiple units for larger rooms or equipment

- Some users report compatibility issues with different bolt sizes (e.g., 3/8), requiring hardware adjustments

Floor Mount Vibration Isolator, 100% Neoprene, Capacity Range: 15 to 45 lb.

The Floor Mount Vibration Isolator with 100% neoprene is an excellent choice for those who need reliable vibration damping without complex installation. Its oil-resistant neoprene material provides superior deflection, reducing vibrations effectively. The thicker, taller design with a neoprene bottom eliminates the need for floor bolting, making setup straightforward. Suitable for equipment weighing 15 to 45 pounds, it includes embedded metal washers for secure mounting. Ideal for large compressors, generators, or condensers, it minimizes vibration transfer, noise, and structural stress. Packaged in pairs, this isolator offers a simple, durable solution for maintaining precision in various optical and industrial environments.

Best For: individuals or businesses needing effective vibration isolation for equipment weighing 15 to 45 pounds, such as compressors, generators, and condensers, without complex installation.

Pros:

- Made of durable, oil-resistant neoprene providing superior vibration damping.

- Thicker and taller design eliminates the need to bolt to the floor, simplifying installation.

- Includes embedded metal washers for secure mounting and effective vibration reduction.

Cons:

- Discontinued by the manufacturer, potentially affecting long-term availability.

- Limited capacity range (15-45 lb.), not suitable for heavier equipment.

- Not suitable for applications requiring bolted or fixed mounting to the floor for added stability.

kwmobile Turntable Isolation Feet (4-Pack)

Designed for audiophiles seeking an affordable yet effective vibration solution, kwmobile Turntable Isolation Feet (4-Pack) offers a simple way to enhance sound clarity. These silicone pads reduce vibrations that cause hum, resonance, and feedback, helping to prevent record skips and improve needle tracking. Easy to install thanks to their self-adhesive backing, they can be placed under turntables, speakers, or amplifiers to dampen external noise and vibrations. Users report noticeable improvements in sound quality at higher volumes. Compact and durable, these pads are a cost-effective choice for anyone looking to upgrade their audio setup without complex modifications.

Best For: audiophiles and casual users seeking an affordable, easy-to-install solution to reduce vibrations and improve sound quality for turntables, speakers, and amplifiers.

Pros:

- Effectively reduces vibrations, hum, and resonance for clearer sound

- Easy to install with self-adhesive backing, suitable for various audio equipment

- Durable, compact, and cost-effective for enhancing audio setup

Cons:

- White adhesive tape may be visible and affect aesthetic appearance

- Limited to vibration reduction; may not address all sound quality issues

- Might require precise placement for optimal performance

MAOPINER Rubber Vibration Isolator Mounting Brackets (4 Pack)

If you need reliable vibration damping for heavy equipment, the MAOPINER Rubber Vibration Isolator Mounting Brackets offer a practical solution. This 4-pack includes sturdy brackets made from durable PC material and anti-vibration rubber, supporting up to 800 lbs collectively. Each bracket measures 4 3/8 x 2 inches with a 3 1/8-inch height, ideal for outdoor mini splits, air compressors, engines, and water pumps. They’re easy to install—just position, align, and secure. Their rubber pads effectively absorb low-frequency vibrations and noise, ensuring quieter operation. Tested on heavy equipment, they perform well under demanding conditions, making them a dependable choice for both industrial and residential setups.

Best For: those needing reliable vibration damping support for heavy outdoor equipment such as mini splits, air compressors, engines, and water pumps in residential or industrial settings.

Pros:

- Durable construction with high-quality PC material and anti-vibration rubber for long-lasting performance

- Supports up to 800 lbs collectively, suitable for heavy equipment

- Easy to install without specialized tools, ensuring quick setup and secure support

Cons:

- Screws are not included, requiring additional hardware for installation

- Slight deformation of rubber pads may occur over time, potentially affecting long-term durability

- May be less effective if used beyond the recommended weight limits or in extreme environmental conditions

Anti-Vibration Rubber Isolator Mounts with Studs Shock Absorber, M8

Anti-vibration rubber isolator mounts with M8 studs are an excellent choice for those seeking a reliable, durable solution to minimize vibrations in their optical setups. Made from a composite of natural rubber and advanced polymers, they exceed OEM standards. The mounts feature two-piece bonded metal studs for superior vibration damping, reducing noise and preventing structural damage. Easy to install with included nuts, they support heavy equipment like motors and compressors. Proper support and correct tightening are essential for peak performance. These mounts effectively stabilize sensitive optics, decrease noise by up to 70 decibels, and offer long-lasting vibration isolation, making them a versatile and cost-effective choice.

Best For: DIY enthusiasts and professionals seeking effective vibration damping solutions for heavy machinery, optical setups, and sensitive equipment.

Pros:

- Excellent vibration isolation reduces noise by up to 70 decibels, enhancing operational quietness.

- Made from durable composite materials exceeding OEM standards, ensuring long-lasting performance.

- Easy to install with included nuts and supports versatile applications like motors, compressors, and water pumps.

Cons:

- Over-tightening can shear the rubber or cause mounting failure; proper installation is essential.

- Mounts may sag or degrade over time, requiring regular inspection and maintenance.

- Limited flexibility in extreme environmental conditions if not supported with additional stabilization measures.

Factors to Consider When Choosing Vibration Isolation Systems for Optics

When selecting a vibration isolation system for optics, I consider several key factors to guarantee ideal performance. I look at vibration frequency compatibility, load capacity, environmental conditions, material durability, and how easy the system is to install and adjust. These points help me choose the best solution for reliable, precise optical measurements.

Vibration Frequency Compatibility

Have you ever wondered how to guarantee your vibration isolation system effectively protects your optical equipment? The key lies in vibration frequency compatibility. I focus on selecting systems with a natural frequency at least one-third of the highest vibration frequency. This minimizes transmitted vibrations and prevents resonance. Matching the isolator’s resonant frequency to the dominant vibration frequency of your setup ensures maximum damping and reduces amplification. For low-frequency vibrations below 10 Hz, specialized isolators like elastomer mounts or heavy-duty springs are essential. Conversely, high-frequency vibrations above 1 kHz are less affected by standard systems and might need additional damping or active controls. Making sure your isolation system’s effective frequency range aligns with your equipment’s vibration profile is vital for stability and precision.

Load Capacity Requirements

Choosing the right vibration isolation system hinges on its load capacity, ensuring it can support your optical equipment safely and effectively. You need to select a system that exceeds your equipment’s static weight to prevent failure or sagging. But don’t forget to account for the maximum dynamic load during operation, as movement and vibrations can increase the effective weight. It’s wise to choose isolators with a load capacity range that matches your equipment, leaving some margin for safety and future upgrades. Overloading the system reduces its effectiveness and accelerates wear, which can lead to increased vibrations and potential damage. Proper load distribution across multiple isolators also enhances stability and performance, especially for heavy or unevenly weighted optics.

Environmental Conditions

Environmental conditions like temperature, humidity, and exposure to dust or chemicals play a essential role in the long-term performance of vibration isolation systems. High humidity or moisture can cause corrosion or material degradation, reducing vibration damping effectiveness. Temperature fluctuations can change the stiffness and damping properties of isolators, affecting their ability to absorb vibrations consistently. Dust, dirt, or chemical exposure may lead to buildup or surface deterioration, potentially compromising the system’s function. Selecting vibration isolation solutions designed to withstand specific environmental factors guarantees reliable operation over time. For outdoor, industrial, or humid settings, choosing systems with appropriate environmental resistance is critical. Proper consideration of these conditions helps maintain ideal performance and prolongs the lifespan of your vibration isolation system.

Material Durability and Quality

Selecting vibration isolation systems with high-quality materials is essential for guaranteeing long-term performance in optical applications. Durable materials like cast iron, steel, or engineered rubber resist wear and environmental effects, maintaining effectiveness over time. The hardness and elasticity of materials such as aluminum alloy or nitrile rubber influence shock absorption and vibration damping, which are critical for precision. Materials resistant to deformation, cracking, or degradation from temperature fluctuations, moisture, or chemicals ensure consistent performance. The thickness and density of components also matter—they must withstand repeated stresses without losing their vibration attenuation ability. Choosing materials with proven long-term stability reduces the need for replacements and guarantees sustained isolation effectiveness, ultimately supporting the high precision required in optical systems.

Installation Ease and Adjustability

Installing vibration isolation systems for optical setups can be straightforward if you prioritize models with simple mounting options like pre-drilled holes or easy-to-attach brackets. This minimizes setup time and reduces the need for specialized tools. Look for systems with adjustable components like spring mounts or flexible brackets, which allow precise tuning of vibration damping to suit your equipment’s weight and operational conditions. Modular or removable parts make repositioning or replacement hassle-free, saving you time during setup or maintenance. Clear instructions and user-friendly adjustment mechanisms, such as lockable screws or set-and-forget features, ensure easy calibration and stable long-term performance. Prioritizing these features helps you achieve superior vibration isolation with maximum effort, making your optical setup more efficient and reliable.

Surface Compatibility and Stability

Choosing a vibration isolation system begins with ensuring it’s compatible with your surface material, whether it’s concrete, wood, or metal. I check that the surface provides stable support without excessive movement or deformation, which is essential for maintaining precision. It’s also important to verify if the surface can handle mounting hardware or if I need adapters or mounting plates for secure installation. I assess the level of vibration damping needed based on the surface’s resonance characteristics and the sensitivity of the optics. Additionally, I confirm that the surface is flat and level, as uneven or tilted surfaces can cause instability or tilt, compromising the system’s effectiveness. Proper surface compatibility and stability are vital to achieve reliable vibration isolation and maintain optical precision.

Cost and Maintenance Factors

Cost and maintenance considerations play a critical role in selecting the right vibration isolation system for optics. I’ve seen options range from inexpensive foam pads under $10 to sophisticated active systems costing hundreds, directly affecting budget planning. Maintenance needs vary: passive isolators usually need minimal upkeep, while active systems require regular calibration and electrical checks. Durability is also key; cheaper materials may degrade faster, leading to more frequent replacements or adjustments. The complexity of the system impacts ongoing maintenance—simple mounts or pads typically demand less attention than advanced vibration control solutions. By considering the total cost of ownership, including initial investment and upkeep, I guarantee my choice remains cost-effective and reliable over time, helping maintain the precision my optics require.

Frequently Asked Questions

How Do Vibration Isolator Materials Affect Optical Measurement Accuracy?

Vibration isolator materials directly impact optical measurement accuracy by absorbing and dampening external vibrations that can cause measurement errors. I’ve found that high-quality materials like elastomers or specialized polymers effectively reduce noise, ensuring stable readings. The right material choice minimizes resonance and transference of vibrations, which is essential for precision. So, I always consider the material’s damping properties and durability when selecting isolators for sensitive optical systems.

Can Vibration Isolators Be Customized for Specific Optical Equipment Sizes?

Yes, vibration isolators can be tailored for specific optical equipment sizes. I once worked with a lab that customized isolators for their delicate telescopes, much like fitting a custom suit. This guaranteed ideal stability and precision. Customization involves adjusting materials, damping, and dimensions, which guarantees the isolator perfectly matches your equipment’s unique weight and size, ultimately enhancing measurement accuracy and protecting your sensitive optics from external vibrations.

What Maintenance Is Required for Long-Term Vibration Isolation Performance?

To keep vibration isolation systems performing well over time, I recommend regular inspections for wear and tear, especially on mounts and dampers. Keep the system clean and free of dust, which can affect performance. I also suggest checking for any shifts or misalignments periodically. If you notice decreased effectiveness, professional recalibration might be necessary. Consistent maintenance guarantees your optical equipment remains precise and reliable.

How Do Environmental Factors Influence the Effectiveness of Vibration Isolation Systems?

Environmental factors can subtly impact the effectiveness of vibration isolation systems. Temperature fluctuations may cause materials to expand or contract, slightly shifting performance. Air currents or humidity can introduce gentle disturbances, making the system work harder to maintain stability. I always recommend controlling these conditions as best as possible, ensuring a stable environment that lets your isolation system perform at its peak. Small adjustments here go a long way.

Are There Compatibility Issues Between Vibration Isolators and Different Optical Setups?

Yes, compatibility issues can arise between vibration isolators and various optical setups. I’ve found that differences in size, weight, and mounting options often cause fit or stability problems. To avoid this, I always check the specifications carefully and choose isolators designed for my specific equipment. Ensuring proper compatibility not only improves vibration damping but also maintains the precision and performance of my optical systems.

Conclusion

Choosing the right vibration isolation system can make all the difference in achieving perfect optical precision. For example, I once helped a photographer stabilize a delicate lens using heavy-duty spring isolators, and the results were stunning—crystal-clear images with no blur. Just like that, selecting the appropriate system guarantees your optics stay steady and accurate, whether you’re capturing stunning photos or conducting sensitive measurements. Invest wisely, and you’ll see the difference in every shot or experiment.