If you’re looking for the top high-precision motorized stages in 2025, I can guide you through the best options that combine exceptional accuracy, durability, and flexible control. Models like the PP110 linear stage and TBVECHI HT03RA100 rotating platform offer repeatability down to 0.005°, load capacities up to 45kg, and smooth, quiet operation. Exploring these selections will help you find the perfect solution for your scientific and industrial needs—stay with me to discover more.

Key Takeaways

- Highlight top models with advanced materials, high accuracy, and versatile control options for demanding scientific and industrial applications.

- Emphasize performance metrics like resolution, repeatability, load capacity, and maximum speed for precise movement.

- Cover construction features such as aluminum alloy bodies, worm gear transmissions, and bearing-guided rails ensuring durability and stability.

- Discuss control interfaces, integration options, and suitability for laser, optical testing, and automation setups.

- Address limitations like load capacity, size, and speed to inform optimal selection for specific high-precision tasks.

PP110-50-5040 High Precision Motorized Linear Stage High Precision Motorized Translation Stage High Precision Motorized Stage

1. Travel range: 50mm

As an affiliate, we earn on qualifying purchases.

High Precision Motorized Linear Stage

If you’re looking for a stage that delivers exceptional accuracy and smooth motion, the PP110-50-5040 high precision motorized linear stage is the ideal choice. It offers a 50mm travel range and a 50mm × 40mm platform, built from durable aluminum alloy with a black-anodized surface for corrosion resistance. Its high-precision grinding screw with a 1mm lead, paired with a precise slide rail, ensures smooth, controlled movement. With a stepper motor (model 42) providing a resolution of 5μm (or 0.625μm with 8 MS) and a repeatability of 2μm, it’s perfect for demanding applications requiring precise translation and positioning.

Best For: researchers and engineers requiring precise, smooth linear motion for optical, scientific, or automation applications.

Pros:

- High accuracy with a repeatability of 2μm and resolution up to 0.625μm with 8 MS

- Durable construction with corrosion-resistant black-anodized aluminum alloy surface

- Smooth and controlled movement thanks to high-precision grinding screw and slide rail

Cons:

- Stepper motor controllers are sold separately, adding to overall cost and setup complexity

- Limited maximum load capacity of 1kg may not suit heavier applications

- Travel range is limited to 50mm, which may not be sufficient for larger-scale positioning needs

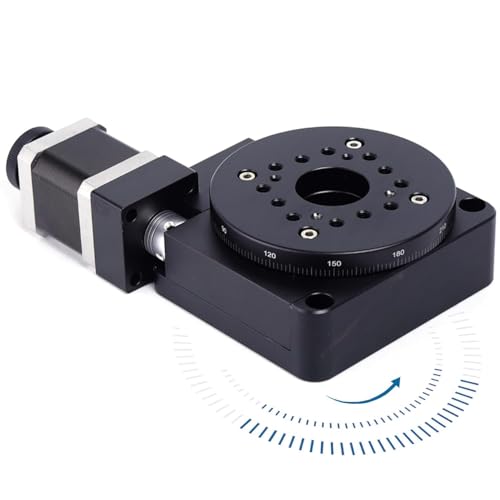

Rotating Platform TBVECHI HT03RA100 Precision Electric Rotating Machine Optical Rotating Platform Motorized Rotation Stage 100mm Bearing Scale (HT03RA100)

HT03RA100 Rotating Platform: HT03RA100 Precision Electric Rotating Machine Optical Rotating Platform Motorized Rotation Stage 100mm Bearing Scale. Fine...

As an affiliate, we earn on qualifying purchases.

Rotating Platform TBVECHI HT03RA100 Precision Electric Rotating Stage

The TBVECHI HT03RA100 Precision Electric Rotating Stage is an ideal choice for professionals requiring high-accuracy rotational positioning in applications like laser machining, 3D scanning, or measurement systems. Its 100mm bearing scale and smooth worm drive guarantee precise, backlash-free movement. The high-quality elastic coupling guarantees silent, synchronized operation, while the scale on the outer ring allows easy setup. Its versatile design supports flat, vertical, or inverted orientations. Built with advanced technology, durable materials, and high-precision shafting, it offers reliable, long-lasting performance. With limit and zero functions, plus customizable options, this stage provides unmatched accuracy and flexibility for demanding scientific and industrial tasks.

Best For: professionals in laser machining, 3D scanning, and measurement systems seeking high-precision rotational positioning.

Pros:

- Provides high-accuracy, backlash-free rotation with a 100mm bearing scale.

- Supports versatile orientations including flat, vertical, and inverted setups.

- Durable construction with advanced materials and customizable options for various applications.

Cons:

- Prototype stage with standard stepper motor may require upgrades for specific needs.

- No optical angle feedback support included, limiting some high-precision control scenarios.

- Compatibility with certain motion controllers may require additional configuration or customization.

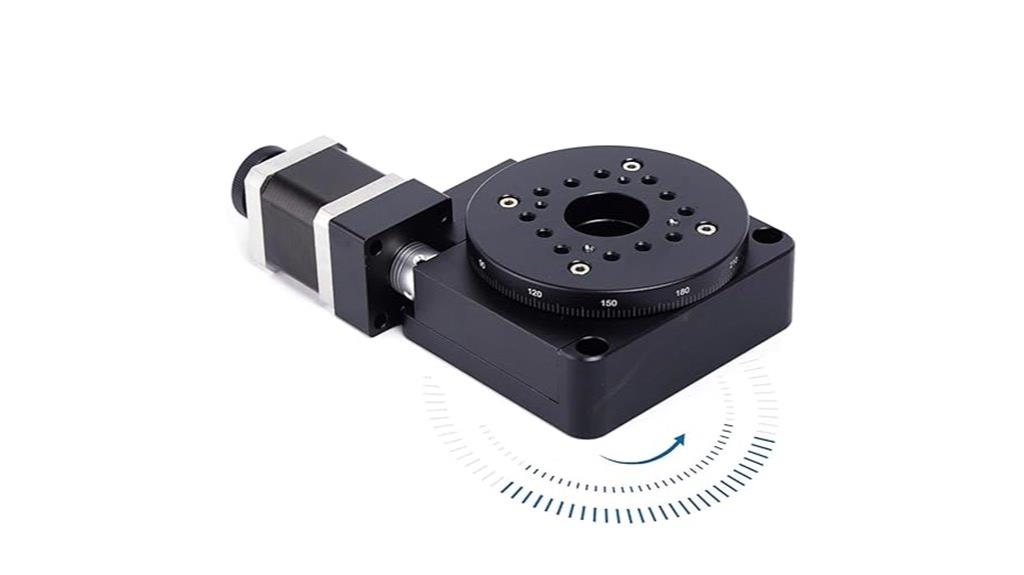

Rotating Platform, 360° Electric Optical Rotating Platform 100MM High-Precision Bearing Rotary Table Worm Gear Transmission Motorized Rotation Stage for Precision Machining, 3D Scanning Measurement

High-precision electric rotating platform, new construction, new technology; key indicators have passed strict inspection. This series of products...

As an affiliate, we earn on qualifying purchases.

Rotating Platform with 360° Rotation for Precision Machining and 3D Scanning

A rotating platform with 360° rotation is an ideal choice for professionals engaged in precision machining and 3D scanning, especially when accuracy and smooth movement are critical. It features a high-precision 100mm bearing and worm gear transmission, ensuring precise, noise-free rotation. The platform supports versatile setups—flat, vertical, or inverted—making it adaptable for various applications. Its outer scale simplifies positioning and measurement, while the steel cup and friction-resistant materials guarantee durability and high load capacity. With customizable control options like stepper or servo motors and flexible interfaces, this platform seamlessly integrates into automated systems, delivering reliable, accurate rotation essential for scientific and industrial tasks.

Best For: professionals and researchers in precision machining, 3D scanning, and industrial automation seeking highly accurate, smooth, and versatile rotary positioning solutions.

Pros:

- High-precision 360° rotation with a 100mm bearing and worm gear transmission for exceptional accuracy.

- Versatile setup options including flat, vertical, and inverted orientations for broad application flexibility.

- Easy to read outer scale and customizable control interfaces, supporting seamless integration into automated systems.

Cons:

- May require specialized knowledge for optimal customization and integration with existing systems.

- Slightly higher cost due to its high-precision components and durability features.

- Potential size and weight constraints depending on application space and load requirements.

CNCTOPBAOS Electric Rotating Machine,Φ100mm Bearing Scale Optical Rotating Platform Motorized Rotation Stage,360° Precision Worm Gear Rotary Table Reduction Ratio 1/180 Load 99lb 45kg RA100

Introduction: This is a high-precision electric rotary machine that uses special technology worm gear transmission and imported ultra...

As an affiliate, we earn on qualifying purchases.

CNCTOPBAOS Electric Rotating Machine, Rotary Table with Worm Gear

Designed for demanding precision tasks, the CNCTOPBAOS RA100 rotary table with worm gear offers exceptional accuracy and stability. Its Φ100mm aluminum platform features high-precision worm gear transmission with a 1/180 reduction ratio, providing 360° rotation with a repeatability of 0.005°. With a resolution of 0.01° without subdivision and 0.0005° with 20 subdivisions, it guarantees precise positioning. The platform supports loads up to 45kg and rotates at speeds up to 25°/sec. Built with high-quality materials like carburized alloy steel and copper turbines, and equipped with bearing-guided rails, it delivers smooth, stable, and reliable rotation for advanced industrial and scientific applications.

Best For: precision engineers and researchers requiring high-accuracy rotational stages for industrial automation, scientific experiments, and measurement systems.

Pros:

- High-precision worm gear transmission with 1/180 reduction ratio for accurate positioning

- Excellent repeatability of 0.005° and resolution down to 0.0005° with subdivisions

- Robust construction with high-quality materials like carburized alloy steel and copper turbines for reliable performance

Cons:

- Limited maximum rotation speed of 25°/sec, which may not suit high-speed applications

- Load capacity of 45kg might be insufficient for very heavy equipment or setups

- The specialized design and materials could result in higher cost compared to simpler rotary stages

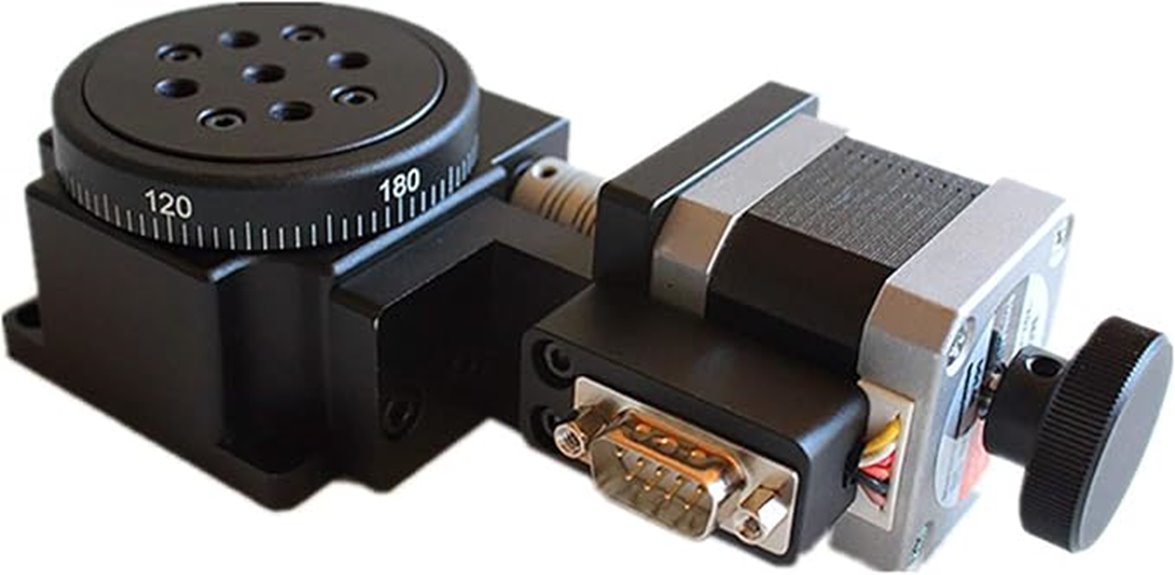

Electric Rotating Stage for Laser and 3D Measurement

If you’re working on laser precision machining, 3D scanning, or measurement systems, the HT03RA100 electric rotating stage is an ideal choice. It features a robust worm gear transmission, offering high rotation accuracy and stability. With a 100mm diameter table and a load capacity of 45kg, it suits flat, vertical, or inverted setups. The stage provides a resolution of 0.01°, with optional 0.0005° for finer control, and repeatability within 0.005°. Its electronic control interfaces via RS232, allowing easy integration into automated systems. Built from black anodized aluminum, it guarantees durability, precision, and noise-free operation—perfect for demanding scientific and industrial applications.

Best For: professionals and researchers involved in laser precision machining, 3D scanning, and measurement systems seeking high accuracy and stability in rotation stages.

Pros:

- High rotation accuracy with resolutions as fine as 0.0005° for detailed precision.

- Robust construction with black anodized aluminum ensures durability and noise-free operation.

- Supports various setups including flat, vertical, and inverted orientations with customizable control options.

Cons:

- Slight color differences due to lighting conditions may affect visual assessment.

- Manual measurements can introduce errors up to 1-3cm; precise calibration is necessary.

- Limited maximum rotation speed of 25°/sec may be insufficient for extremely fast applications.

DNYSYSJ Electric 360° Rotating Platform with Worm Gear (100mm Diameter)

The DNYSYSJ Electric 360° Rotating Platform with Worm Gear (100mm Diameter) stands out as an ideal choice for scientists and engineers needing precise, stable rotation in demanding applications. Its worm gear transmission with a 1/180 reduction ratio guarantees high accuracy and smooth movement, while the aluminum body with a black anodized finish provides durability. With a resolution of 0.01° (or 0.0005° with 20 subdivisions), it guarantees fine positioning and repeatability. Capable of handling loads up to 45kg at speeds up to 25°/sec, it’s suitable for laser machining, optical testing, and other precision tasks, offering reliable performance in various environments.

Best For: scientists, engineers, and technicians seeking precise, stable rotation for laser machining, optical testing, 3D scanning, and scientific experiments.

Pros:

- High-precision resolution of 0.01° (or 0.0005° with 20 subdivisions) ensures accurate positioning.

- Capable of handling loads up to 45kg with a maximum speed of 25°/sec, suitable for demanding tasks.

- Durable aluminum construction with black anodized finish provides long-lasting reliability and stability.

Cons:

- Weight of 1.7kg might require sturdy mounting for certain applications.

- Standard prototype uses a 42-stepper motor, which may need upgrading for ultra-smooth operation in some cases.

- Limited to a maximum diameter of 100mm, which may not accommodate larger setups.

Rotating Platform HT03RA100 Electric Rotating Machine

Are you looking for a highly accurate and versatile rotation platform for precision applications? The HT03RA100 electric rotating machine fits that need perfectly. With a 100mm anodized aluminum table, it offers smooth 360° rotation at speeds up to 25° per second. Its worm gear transmission with a 1/180 ratio guarantees reliable, high-precision movement, supporting loads up to 45kg. The device boasts impressive resolution options—0.01° and 0.0005°—and repeatability of 0.005°. Its flexible design allows vertical, horizontal, or inverted use, making it ideal for scientific, industrial, or measurement tasks requiring pinpoint accuracy.

Best For: precision engineers, researchers, and industrial automation professionals seeking reliable, high-accuracy rotation platforms for scientific, measurement, or manufacturing applications.

Pros:

- High-resolution options of 0.01° and 0.0005° enable precise positioning.

- Supports large loads up to 45kg with stable, smooth operation.

- Versatile mounting orientations (vertical, horizontal, inverted) for diverse setups.

Cons:

- Limited maximum rotation speed of 25° per second may not suit high-speed requirements.

- The device may require additional controllers or motor upgrades for customized automation.

- Its relatively compact size might restrict use with larger or heavier components.

Motorized Rotary Stage for Laser and 3D Scanning

High-precision motorized rotary stages excel in laser and 3D scanning applications, offering exact positioning and smooth rotation essential for detailed measurements. The HT03RA100 model features a 100mm diameter platform with 360° rotation, supporting various mounting orientations. Its aluminum-black anodized body weighs just 1.7kg, with a bearing-guided guide rail ensuring smooth motion. The worm gear with a 1/180 reduction ratio provides high resolution—0.01° or 0.0005° with 20 subdivisions—and an on-axis accuracy of 0.01°. Capable of speeds up to 25°/sec, it supports loads up to 45kg, making it ideal for precise automation, laser, and 3D scanning tasks.

Best For: professionals and researchers requiring high-precision rotation for laser, 3D scanning, and automation applications.

Pros:

- High-resolution rotation with 0.01° and 0.0005° options for precise positioning

- Supports heavy loads up to 45kg with stable aluminum and steel construction

- Smooth, quiet operation due to elastic coupling and fine-ground gears

Cons:

- Limited to a maximum speed of 25°/sec, which may be slow for rapid movements

- Requires external control systems compatible with RS232 or stepper/servo motors

- Slightly heavier and larger packaging, which may impact space or portability

Rotating Platform HT03RA100 Electric Rotating Stage 100mm Motorized Rotation Table

If you need accurate, smooth, and reliable rotation for your scientific experiments or industrial automation projects, the HT03RA100 electric rotating stage is an excellent choice. Its 100mm diameter table, combined with worm gear transmission and friction-resistant materials, guarantees high precision and durability. The scale on the outer ring allows for easy positioning, while the fine grinding worm drive provides quiet, smooth movement. Compatible with various motors and control interfaces like RS232, it offers versatile operation for vertical, horizontal, or inverted setups. Built for stability and large load capacity, this stage guarantees long-lasting performance in demanding environments.

Best For: researchers, industrial automation professionals, and scientists seeking precise, reliable, and versatile rotation stages for experiments or production lines.

Pros:

- High-precision 100mm diameter platform with worm gear transmission for accurate movement

- Quiet, smooth operation with customizable motor options and easy control via RS232 interface

- Durable construction with large load capacity suitable for demanding environments

Cons:

- May require technical expertise for integration with custom control systems

- Limited to a 100mm table size, which might not suit larger applications

- Potential additional cost when selecting advanced motor options or accessories

360° Electric Rotating Platform for Laser and 3D Measurement

The 360° electric rotating platform is an ideal choice for professionals engaged in laser machining and 3D measurement tasks, thanks to its high rotational accuracy and stable movement. With a worm gear transmission and a guide rail bearing, it delivers a design resolution of up to 0.0005°, ensuring precise positioning. Its robust aluminum-black anodized construction supports loads up to 45kg, while features like limit and zero functions enhance control. Capable of operating at speeds up to 25°/sec, it’s suitable for vertical or assembled configurations. Its reliable performance, long lifespan, and flexible control interfaces make it perfect for demanding laser and measurement applications.

Best For: professionals and researchers engaged in laser precision machining, 3D scanning, and high-accuracy measurement tasks requiring stable and highly precise rotational positioning.

Pros:

- High rotational accuracy with a resolution of up to 0.0005°, ensuring precise control.

- Robust construction with aluminum-black anodized material supporting loads up to 45kg.

- Versatile control options including RS232 and customizable motion systems for flexible integration.

Cons:

- Slight measurement deviations may occur due to environmental factors or manufacturing tolerances.

- Limited maximum rotation speed of 25°/sec may not suit very high-speed applications.

- Requires compatible motion controllers and possibly additional setup for full customization.

Electric Rotating Platform, High Precision Motorized Stage

For professionals who require meticulous control over rotation, the Electric Rotating Platform with its 180:1 worm gear drive and 0.01° resolution offers unmatched accuracy. Its 100mm aluminum alloy table is durable and impact-resistant, suitable for industrial, scientific, and automation tasks. The high-precision stepper motor ensures smooth, responsive movement with a load capacity of up to 45kg (99 pounds). Features like fine-tuning adjustments and a bearing-guided guide rail enable precise positioning and repeatability. Compact and lightweight at just 1.71kg, this platform combines reliability with a modern design, making it ideal for demanding applications requiring exact rotational control.

Best For: professionals in industrial automation, scientific research, and precision measurement requiring accurate and reliable rotational control.

Pros:

- High precision with 0.01° resolution and 180:1 worm gear drive for accurate rotation.

- Durable aluminum alloy construction with impact resistance and long-lasting performance.

- Supports heavy loads up to 45kg (99 pounds) with smooth, responsive movement.

Cons:

- Slight color variations may occur due to lighting and manufacturing processes.

- Manual measurement may result in 1-3cm measurement errors.

- Limited to tabletop mounting, which may not suit all installation environments.

Electric Rotating Machine Optical Rotating Platform, 360° Optical High Precision Motorized Rotation Stage, Load 30Kg

Engineers and researchers seeking ultra-precise rotational control will find the Electric Rotating Machine Optical Rotating Platform an ideal choice, thanks to its 360° continuous rotation and high accuracy specifications. This platform features a Ø60mm diameter with a 30kg load capacity, making it suitable for demanding applications. Its worm gear drive guarantees reliable, high-precision movement, while the aluminum alloy construction with a black-anodized finish assures durability. With a design resolution of 0.01° (or 0.0005° with a 20MS driver), it offers exceptional repeatability and minimal backlash. The integrated outer scale and RS232 interface facilitate precise control and seamless integration into complex systems.

Best For: engineers and researchers requiring ultra-precise, high-capacity rotational control for industrial, laboratory, or research applications.

Pros:

- High precision with a resolution of 0.01° (or 0.0005° with a 20MS driver) ensuring accurate positioning.

- Robust construction with durable aluminum alloy and steel components for long-lasting performance.

- Seamless control via integrated outer scale and standard RS232 interface for easy system integration.

Cons:

- Maximum rotational speed limited to 20°/sec, which may not suit ultra-fast rotation needs.

- Weight of 1.2kg and size may require careful handling in some setups.

- Customization options are available but may involve additional costs and lead times.

HT03RA100 Rotating Platform, Precision Electric Rotating Machine 100mm

If you need highly accurate and reliable rotation control in precision applications, the HT03RA100 rotating platform is an excellent choice. Its 100mm table diameter, combined with a 360° rotation range, provides precise positioning up to 0.01°, with optional subdivisions for even finer control. Built with high wear-resistant worm gear and anodized aluminum, it offers durability, stability, and smooth movement. The platform’s scale on the outer ring simplifies initial setup and adjustments. Whether used in laser machining, optical testing, or scientific research, this platform’s advanced technology and versatile orientation support make it ideal for demanding precision tasks.

Best For: professionals and researchers requiring precise, reliable rotation control in laser machining, optical testing, and scientific experiments.

Pros:

- High rotation accuracy up to 0.01°, with optional subdivisions for finer control

- Durable construction with high wear-resistant worm gear and anodized aluminum body

- Versatile operation in flat, vertical, and inverted orientations

Cons:

- Limited maximum rotation speed of 25°/sec, which may not suit high-speed applications

- Requires compatible controller setup for automation, possibly adding complexity

- Slightly heavier weight (about 1.7kg), which may impact portability for some uses

Electric Rotating Platform, 100mm Diameter, Laboratory & Industrial Use

Looking for precise rotation control in laboratory or industrial settings? The Electric Rotating Platform with a 100mm diameter offers high-precision movement ideal for scientific experiments, 3D scanning, and automation. Its aluminum anodized surface supports loads up to 45kg and guarantees durability. Equipped with a stepper motor and worm gear reduction, it achieves a resolution of 0.0005°, providing exceptional accuracy and repeatability. Whether used vertically or integrated with other stages, this platform delivers stable, noise-free rotation at speeds up to 25°/sec. Its compact design and precise mechanics make it a versatile choice for demanding precision applications in both labs and factories.

Best For: researchers, engineers, and technicians requiring high-precision, stable, and versatile rotation control for laboratory experiments, industrial automation, and 3D measurement systems.

Pros:

- High-resolution rotation with 0.0005° accuracy and excellent repeatability of 0.005°

- Durable aluminum anodized surface supports loads up to 45kg, suitable for demanding applications

- Compact design with stable, noise-free operation at speeds up to 25°/sec

Cons:

- Maximum rotation speed may be limiting for applications requiring faster movement

- Limited to a 100mm diameter, which may not accommodate larger samples or components

- Requires careful handling of the worm gear and motor connections to maintain precision over time

Electric Rotating Platform, 100mm High Precision Optical Rotating Stage

The Electric Rotating Platform, 100mm High Precision Optical Rotating Stage, is ideal for professionals requiring ultra-precise rotation and positioning in scientific and industrial applications. Its robust construction features an aluminum, black anodized top board with a guide rail bearing, supporting up to 45kg. With a 360° itinerary and a resolution of 0.01° (or 0.0005° with subdivisions), it delivers exceptional accuracy. Equipped with a scale ring for easy initial positioning and signal output, it works seamlessly with standard interfaces like RS232. Whether for precision machining, 3D scanning, or scientific experiments, this stage offers stability, durability, and customizable control options for demanding tasks.

Best For: professionals demanding ultra-precise rotation and positioning in scientific research, industrial automation, and high-precision measurement systems.

Pros:

- High-precision resolution of 0.01° (or 0.0005° with subdivisions) ensures exceptional accuracy.

- Robust aluminum construction with a 45kg load capacity provides durability and stability for demanding tasks.

- Compatible with standard interfaces like RS232 and customizable options for diverse control needs.

Cons:

- Maximum rotation speed of 25°/sec may be limiting for applications requiring rapid movement.

- Slightly complex setup due to multiple control options and signal outputs.

- The device’s weight and size may require careful handling and integration into existing systems.

Factors to Consider When Choosing High‑Precision Motorized Stages

When selecting high-precision motorized stages, I focus on key factors like resolution, accuracy, and load capacity to guarantee they meet my application’s demands. I also consider control interface compatibility and how smoothly the stage moves without noise, especially in sensitive environments. Finally, environmental factors play a role in choosing a stage that’s reliable and suited for my specific setting.

Resolution and Accuracy

Choosing the right high-precision motorized stage hinges on understanding its resolution and accuracy, as these factors directly impact positioning precision. Higher resolution, such as 0.625μm compared to 5μm, enables finer movements, which is vital for delicate tasks. Absolute accuracy, usually within a few micrometers, determines how precisely the stage reaches and maintains the target position. Repeatability, often within 2μm, shows how consistently it can return to a specific point after multiple movements. Mechanical qualities like straightness and parallelism also affect overall accuracy, ensuring the stage’s movements are true to specifications. When selecting a stage, it’s important to consider both resolution and accuracy to meet the precision demands of your measurement or fabrication tasks effectively.

Load Capacity Limits

Selecting a high-precision motorized stage requires careful attention to its load capacity to guarantee reliable performance. You should always make sure the stage’s load capacity exceeds your application’s maximum payload weight to avoid mechanical stress or failure. These stages typically have load limits ranging from 1kg to over 50kg, depending on design and materials. Exceeding the specified load can decrease accuracy, increase backlash, or damage the stage over time. It’s also important to think about dynamic factors like vibrations or acceleration, which can lower the effective load capacity during operation. Always verify the manufacturer’s maximum load rating and include safety margins in your planning. Proper load management ensures your stage performs accurately and reliably throughout its lifespan.

Control Interface Compatibility

Ensuring your motorized stage’s control interface is compatible with your existing system is vital for smooth operation. I always verify that the interface—such as RS232, DB9, or Ethernet—matches my automation or measurement setup. It’s essential to confirm the stage supports the right communication protocols and command sets to avoid integration issues. I also check if the interface offers sufficient bandwidth and response speed to meet my precision and timing needs. Compatibility with my preferred controller hardware, whether stepper, servo, or custom units, is a must. Additionally, I verify there are reliable software drivers and support available, simplifying setup and ongoing operation. Proper compatibility minimizes downtime and guarantees seamless control, helping me achieve consistent, high-precision results.

Motion Smoothness and Noise

Achieving smooth, quiet motion in high-precision motorized stages hinges on several key mechanical and electrical factors. Using worm gear transmission and elastic couplings helps guarantee synchronized movement with minimal backlash and noise. Fine grinding worm drives provide precise engagement between gears, reducing vibrations and enabling noiseless operation. High-quality shafting and bearing mechanisms support stable, vibration-free motion, which is essential for accuracy. Proper motor selection, like stepper motors with microstepping, improves motion fluidity and cuts down on audible noise during operation. Additionally, maintaining ideal lubrication and alignment of mechanical components reduces friction-induced noise. These combined factors contribute considerably to smoother, quieter stage movements, ensuring peak performance in sensitive applications demanding high precision and minimal disturbance.

Environmental Suitability

When selecting high-precision motorized stages, it’s crucial to take into account how well their environmental compatibility aligns with your specific application conditions. First, verify the stage’s operating temperature range matches your environment, typically from -20°C to +50°C in industrial settings. Confirm that materials like aluminum alloy or anodized surfaces resist corrosion and suit humidity levels. Inspect for sealing and enclosure features, such as dust or waterproof ratings, to safeguard sensitive components from debris and moisture. Compatibility with environmental factors like electromagnetic interference is also vital—proper shielding or grounding maintains accuracy. Lastly, evaluate vibration and shock resistance, especially if your environment involves mechanical disturbances or impacts. These considerations help ensure reliable, precise performance tailored to your application’s environmental challenges.

Customization Options Available

Choosing the right high-precision motorized stage often involves customizing features to match your specific application needs. I look for options like limit switches, zeroing functions, and tailored mounting configurations to guarantee the stage fits my setup perfectly. Many stages support different motors, such as stepper or servo, allowing me to optimize control precision and compatibility with my existing systems. I also customize resolution, load capacity, and travel range to match my task requirements precisely. Control interfaces can be tailored for seamless integration with various motion controllers and communication protocols. Additionally, I can specify custom sizes, materials, or surface treatments to boost durability and environmental resistance. These customization options ensure the stage delivers the exact performance needed for my specialized applications.

Frequently Asked Questions

What Maintenance Is Required for High-Precision Motorized Stages?

To keep high-precision motorized stages performing at their best, I regularly clean and inspect the rails and contact points for dust and debris. I also check for proper lubrication, ensuring smooth movement without resistance. Calibration is essential, so I routinely verify the stage’s accuracy and adjust if needed. Additionally, I monitor for any unusual noises or vibrations and address issues promptly to maintain ideal precision and longevity.

How Do Environmental Factors Affect Stage Accuracy?

Environmental factors critically impact stage accuracy. I’ve found that temperature fluctuations cause expansion or contraction, leading to misalignments. Humidity can cause corrosion or affect electronic components, and vibrations from nearby equipment can disrupt precise movements. To maintain accuracy, I keep the environment stable, control temperature and humidity, and isolate the stages from vibrations. Regular calibration also helps guarantee consistent performance despite environmental changes.

What Is the Typical Lifespan of These Motorized Stages?

I’d say the typical lifespan of these motorized stages ranges from 5 to 10 years, depending on usage and maintenance. Think of it like a high-performance car; regular care extends its life, while neglect shortens it. Proper calibration, clean environments, and timely repairs keep these stages running smoothly longer. So, with good upkeep, you can expect reliable performance and accuracy for many years.

Are Compatibility Features Available for Existing Equipment?

Yes, compatibility features are commonly available for existing equipment. I’ve found that many high-precision motorized stages come with versatile interfaces like USB, Ethernet, or serial connections, making integration straightforward. Manufacturers often provide adapters or software updates to guarantee seamless connectivity. Before purchasing, I recommend checking the specifications to confirm compatibility with your current setup, ensuring smooth operation and avoiding costly modifications later.

How Do I Calibrate and Troubleshoot These Stages Effectively?

Think of calibration as tuning a fine instrument—precision depends on it. I start by aligning the stage with known reference points, then check for any deviations using calibration tools. Troubleshooting means listening carefully to unusual noises or irregular movements, like detecting discord in music. I regularly review system logs and update firmware, ensuring everything hums smoothly. Consistent calibration and attentive troubleshooting keep my stages performing at peak accuracy.

Conclusion

Ultimately, choosing the right high-precision motorized stage is about more than specs—it’s about trusting your vision to be accurately realized. As I’ve explored, each stage offers a unique blend of precision and reliability. Sometimes, it’s the smallest details that make the biggest difference. When you align your needs with the right technology, you’re not just selecting equipment—you’re revealing the potential for breakthroughs that begin with precision.