Nanotech in textile waste reduction helps you by creating fabrics that are more recyclable, durable, and stain-resistant. These innovations extend garment life, reducing how often you need to replace or wash clothes, which lessens environmental impact. Nanoscale coatings keep fabrics strong during recycling and resist water, oil, and dirt, so clothes stay cleaner longer. If you keep exploring, you’ll discover how these advancements support a more sustainable and eco-friendly textile industry.

Key Takeaways

- Nanotech enables textiles to be more easily recycled without degrading fabric quality.

- Nano-coatings improve fiber durability, extending garment lifespan and reducing waste.

- Advanced nanotech treatments create stain-resistant fabrics that require less frequent washing.

- Combining recyclability and stain resistance in nanotech-enhanced textiles minimizes landfill waste.

- Nano-enabled textile innovations support sustainable resource use and promote eco-friendly disposal practices.

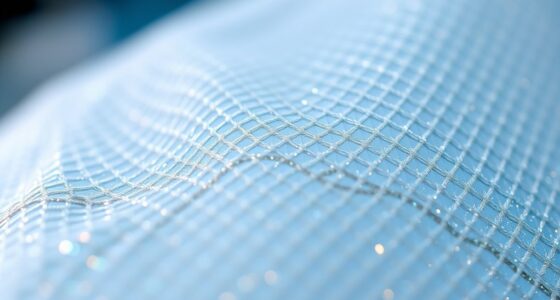

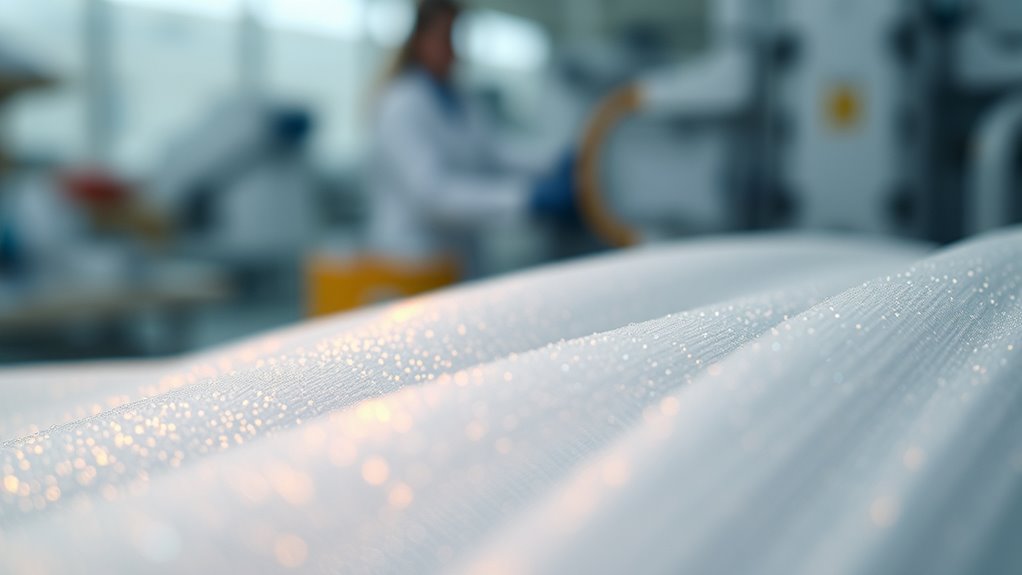

Nanotechnology is revolutionizing efforts to reduce textile waste by enabling the development of smarter, more sustainable materials. One of the most exciting advancements is in fiber recycling. Traditional recycling methods often degrade fabric quality, making it difficult to reuse fibers effectively. But with nanotech, manufacturers can create textiles that are easier to break down at the end of their life cycle, allowing for cleaner, more efficient fiber recycling. Nanoscale coatings and treatments help fibers maintain their strength during recycling processes, so recycled textiles retain their durability and appearance. This means less waste ends up in landfills, and more fibers can be reused multiple times, reducing the need for virgin materials and cutting down on environmental impact.

Alongside fiber recycling, nanotechnology is also enhancing stain resistance in textiles. You’ve probably experienced how difficult it can be to keep clothes looking new after a spill or stain. Nanotech treatments create a protective barrier on fabric surfaces, making them highly resistant to liquids and stains. These ultra-thin coatings are invisible to the naked eye but markedly improve the fabric’s ability to repel water, oil, and dirt. This not only keeps your clothes cleaner longer but also means fewer washes, less water consumption, and reduced detergent use. The stain-resistant properties achieved through nanotech extend the lifespan of garments, reducing the frequency of disposal and contributing to waste reduction.

What makes nanotech even more compelling is its ability to combine these features into a single fabric. Imagine a shirt that’s both easily recyclable and stain-resistant, all thanks to nano-enhanced treatments. These innovations can be applied during the manufacturing process, ensuring that textiles are designed with sustainability in mind from the outset. You benefit by wearing clothes that stay cleaner longer, last for more washes, and are easier to recycle at the end of their use, creating a cycle that minimizes waste and maximizes resource efficiency. Additionally, advancements in merchant services can support the sustainable textile industry by facilitating efficient, secure, and transparent transactions, encouraging eco-friendly purchasing options.

Frequently Asked Questions

How Cost-Effective Is Nanotech Implementation in Textile Manufacturing?

Nanotech implementation in textile manufacturing can be cost-effective over time, but it depends on your initial investment and ongoing maintenance. You should conduct a thorough cost analysis to weigh benefits against expenses. Be prepared for investment challenges, such as high upfront costs and technical hurdles. While the technology offers waste reduction advantages, balancing short-term costs with long-term savings is essential for making it financially viable.

Are There Environmental Risks Associated With Nanomaterials in Textiles?

You should be aware that nanomaterials in textiles can pose environmental risks, including environmental toxicity and challenges in waste management. These tiny particles might leach into soil and water, affecting ecosystems and human health. Proper disposal methods are vital to minimize these risks. By understanding potential environmental impacts, you can make more informed decisions about using nanotech in textiles and support sustainable practices.

Can Nanotech Be Integrated Into Existing Textile Production Lines Easily?

Imagine transforming your textile production like a butterfly emerging—elegant and seamless. Nanotech can be integrated into existing lines, but you’ll face scalability challenges that require careful planning. Ease of integration depends on your equipment and expertise, yet with proper adjustments, the process becomes smoother. While it may seem intimidating at first, overcoming these hurdles opens innovative benefits, making your textiles smarter, more sustainable, and ready for the future.

What Is the Lifespan of Nanotech-Enhanced Textiles?

The lifespan of nanotech-enhanced textiles largely depends on durability factors and wear resistance, but generally, they last longer than conventional fabrics. You’ll find that nanotech improves resistance to fading, tearing, and stains, extending usability. Proper care, like gentle washing and avoiding harsh chemicals, can further enhance their durability. So, with good maintenance, your nanotech textiles can stay in great condition for years, offering both longevity and sustained performance.

Are There Regulatory Standards for Nanotech Use in Textiles?

Think of regulatory standards for nanotech in textiles like a safety net—designed to catch potential issues before they become problems. Currently, you need to make certain your products meet regulatory compliance and safety standards set by agencies like the EPA and FDA. While strict guidelines are evolving, staying informed and adhering to existing regulations helps protect consumers and the environment, giving you confidence in your innovative textile applications.

Conclusion

By harnessing nanotech, you can markedly cut textile waste—reducing landfill contributions by up to 30% in some cases. Imagine billions of micro-scale particles working silently to make fabrics more durable and easier to recycle. This innovative approach not only minimizes environmental impact but also transforms how you view sustainable fashion. Embrace nanotech, and you’re helping create a cleaner, greener planet—one tiny particle at a time.