Nanomaterials enhance fire-resistant building materials by improving strength, durability, and safety through innovative nanostructures and coatings. They create protective barriers that block heat and gases, resist decomposition at high temperatures, and absorb heat more effectively. These materials are used in paints, insulation, and composites to boost fire resistance and longevity. As you explore further, you’ll discover how ongoing research is shaping safer, more sustainable fire-resistant structures for the future.

Key Takeaways

- Nanomaterials like nanosilica and nanoclays enhance fire resistance by forming protective barrier layers and improving thermal stability.

- They are incorporated into coatings, paints, and composites to provide flame retardancy, smoke suppression, and structural reinforcement.

- Nanomaterials improve fire safety through heat absorption, barrier formation, and decomposition resistance at high temperatures.

- Challenges include scaling production, environmental impact, high costs, and the need for regulatory standards and safety testing.

- Future innovations focus on sustainable, eco-friendly nanomaterials with enhanced performance and adaptable fire-resistant building applications.

Overview of Nanomaterials in Construction

Nanomaterials have emerged as a transformative technology in the construction industry, offering enhanced performance and new functionalities. These tiny materials improve strength, durability, and fire resistance in building components. However, you should also consider concerns about nanomaterial toxicity, which could pose health risks during manufacturing and application. Additionally, their environmental impact is an important factor; some nanomaterials may persist in ecosystems or generate waste that’s hard to manage. As you incorporate nanomaterials into construction, weigh these potential risks against the benefits. Understanding their behavior at the nanoscale helps you make informed decisions that balance innovation with safety. Ongoing research aims to minimize adverse effects, ensuring nanomaterials contribute positively without compromising health or the environment. Understanding their behavior at the nanoscale helps you make informed decisions that balance innovation with safety.

Types of Nanomaterials Used for Fire Resistance

Building materials enhanced with nanomaterials can substantially improve fire resistance, thanks to their unique properties at the nanoscale. Common types include carbon nanotubes, nanosilica, and nanoclays, each contributing to fire safety by forming barrier layers or enhancing char formation. These nanomaterials are created through specialized nanomaterial synthesis techniques, ensuring uniform dispersion within matrices. Their integration results in nanocomposite durability, maintaining structural integrity under high temperatures. Here’s a quick comparison:

| Nanomaterial Type | Key Benefit |

|---|---|

| Carbon Nanotubes | Improved mechanical strength |

| Nanosilica | Enhanced thermal stability |

| Nanoclays | Flame retardancy |

| Metal Oxides | Smoke suppression |

Mechanisms Behind Enhanced Fire Safety

You can see how nanomaterials improve fire safety through barrier formation, which slows down the spread of flames. They also enhance heat absorption, reducing the temperature rise in materials during a fire. Understanding these mechanisms shows how nanomaterials make building materials markedly more fire-resistant. Additionally, nanomaterials contribute to fire-resistant properties by enabling the development of intelligent materials that adapt to changing conditions during a fire.

Nanomaterial Barrier Formation

How do nanomaterials enhance fire safety through barrier formation? They create robust, protective layers that slow or prevent fire progression by leveraging self-assembly processes and nanostructure stability. When applied, nanomaterials form dense, cohesive barriers that act like shields. Picture these barriers as:

- A tightly woven mesh that blocks heat and gases.

- An interconnected network preventing the passage of flames.

- A stable nanostructure resisting decomposition under high temperatures.

- A self-assembled coating that adapts to surface irregularities, sealing microscopic cracks.

This self-assembly guarantees uniform coverage and durability. The nanomaterials’ stability maintains the barrier’s integrity during fire exposure, effectively delaying combustion and protecting underlying materials from heat and smoke damage.

Heat Absorption Enhancement

Nanomaterials not only form protective barriers but also markedly boost a material’s ability to absorb heat during a fire. They do this by modifying thermal conductivity, allowing heat to spread more evenly and slow down temperature spikes. This enhanced heat absorption facilitates energy dissipation, preventing localized overheating that can cause structural failure. Using nanomaterials with high surface area-to-volume ratios improves heat transfer efficiency.

| Nanomaterial Type | Effect on Thermal Conductivity | Impact on Energy Dissipation |

|---|---|---|

| Carbon Nanotubes | Increases | Enhances |

| Metal Oxide NPs | Slightly increases | Improves |

| Silica NPs | Maintains or reduces | Stabilizes |

| Graphene Nanosheets | Substantially increases | Promotes |

| Polymer-based NPs | Varies, often decreases | Damps |

Advantages of Incorporating Nanomaterials

Incorporating nanomaterials into fire-resistant building materials offers significant advantages that enhance both safety and performance. You’ll notice improved durability, as nanomaterials strengthen structural elements against heat and flames. They also boost cost efficiency by reducing the amount of material needed for effective fire resistance, saving money long-term. Additionally, nanomaterials provide aesthetic versatility, allowing for seamless integration into various design styles without compromising fire safety standards. Imagine:

- Thin, transparent coatings that preserve the building’s appearance

- Lightweight panels with enhanced fireproofing capabilities

- Uniform finishes that blend seamlessly into existing structures

- Customizable textures and colors for aesthetic appeal

- The use of digital platforms and virtual collaboration to facilitate innovative development in nanomaterials for fire-resistant applications remote hackathons.

These benefits make nanomaterials a smart choice for creating safer, more versatile, and visually appealing building materials.

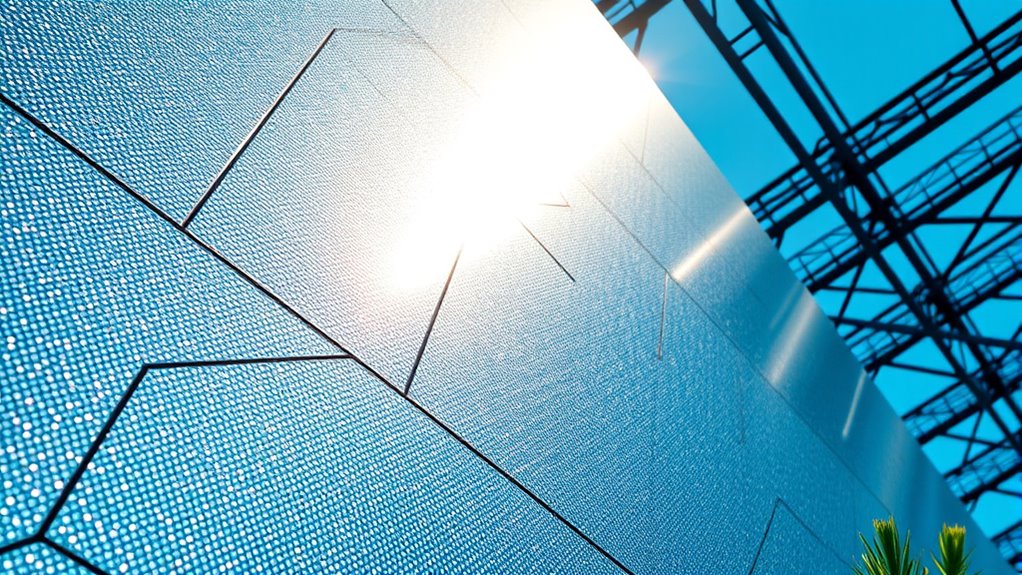

Current Applications in Building Materials

Recent advancements have seen nanomaterials being integrated into a variety of building products to enhance fire resistance. These applications improve nanomaterial durability and enable the creation of cost-effective nanocomposites. You’ll find nanomaterials in insulation, coatings, and structural components, providing improved fire retardancy and longevity. For example, nanocoatings can create fire-resistant surfaces, while nanocomposites strengthen materials without adding weight. The table below highlights key applications:

| Material Type | Function | Benefits |

|---|---|---|

| Fire-resistant paint | Coats surfaces to prevent fire spread | Enhances durability, cost-effective |

| Insulation panels | Reduce heat transfer | Improves fire safety, durability |

| Structural composites | Reinforces building frameworks | Increases longevity, cost savings |

| Sealants | Seal gaps to prevent flame propagation | Improved fire barrier, durable |

Nanomaterials can also improve the fire retardant properties of building components, making structures safer during emergencies.

Challenges and Limitations of Nanotechnology Integration

Despite the promising benefits of nanotechnology in fire-resistant building materials, several challenges hinder widespread adoption. Scalability issues make it difficult to produce nanomaterials in large quantities without losing quality or increasing costs. Environmental impacts raise concerns about nanoparticle release during manufacturing or disposal, potentially harming ecosystems. Additionally, the high costs of nanomaterials limit their commercial viability. Regulatory frameworks lag behind technological advancements, creating uncertainty around safety standards. Finally, integrating nanomaterials into existing building processes requires specialized equipment and expertise, complicating implementation. Visualize manufacturing plants overwhelmed with tiny particles, environmental hazards lurking unseen, and costs spiraling beyond reach. Overcoming these hurdles is essential to release nanotechnology’s full potential for fire-resistant construction. Nanomaterial safety remains a critical aspect that must be addressed through rigorous testing and regulation.

Future Perspectives and Innovations

Looking ahead, you’ll see emerging nanomaterial technologies revolutionize fire-resistant building materials with enhanced performance. Sustainable solutions will become more practical, reducing environmental impact while increasing safety. Additionally, advances in regulations and safety standards will support wider adoption and responsible innovation in this field. Incorporating ethical considerations into research and development will ensure that these innovations are both effective and socially responsible.

Emerging Nanomaterial Technologies

Emerging nanomaterial technologies hold tremendous potential to revolutionize fire-resistant building materials by enabling stronger, lighter, and more effective solutions. Advances in nanomaterial synthesis allow you to tailor properties at the atomic level, optimizing fire resistance. Nanostructure characterization helps you understand how nanoscale features influence performance, ensuring reliable integration into construction materials. Imagine:

- Precise manipulation of nanostructures for enhanced thermal stability.

- Rapid development of fire-retardant coatings with improved adhesion.

- Real-time monitoring of nanomaterial behavior under extreme heat.

- Customizable nanostructures that adapt to varying fire conditions.

These innovations open pathways for smarter, safer buildings, pushing the boundaries of traditional materials and creating new opportunities for fire safety in construction.

Sustainable Fire-Resistance Solutions

Advancements in nanomaterial technologies pave the way for developing sustainable fire-resistant building solutions that prioritize environmental health and resource efficiency. You’re now exploring options that reduce nanomaterial toxicity, minimizing potential health risks associated with their use. Focus shifts toward designing eco-friendly nanomaterials that lessen environmental impact during manufacturing, application, and disposal. Innovative approaches aim to develop biodegradable or recyclable nanomaterials, ensuring fire-resistant coatings and composites are both effective and sustainable. By addressing toxicity concerns and environmental footprints, these solutions support greener construction practices. Your goal is to integrate nanomaterials that uphold safety standards without compromising ecological integrity, paving the way for fire-resistant materials that are both high-performing and environmentally responsible. This balance is essential for future-proofing sustainable building technologies.

Regulatory and Safety Advances

How will regulatory frameworks adapt to the rapid development of nanomaterials for fire-resistant building applications? You’ll see building code updates that incorporate specific guidelines for nanomaterial safety, ensuring new materials meet rigorous standards. Safety standard compliance will become more streamlined, with clear testing protocols for nanomaterial fire resistance and toxicity. Visualize a future where regulators:

- Establish detailed testing procedures for nanomaterial fire behavior

- Develop standardized reporting for environmental and health impacts

- Implement certification processes that validate safety and performance

- Create adaptable regulations that evolve with technological advances

These measures will help you stay ahead in integrating innovative nanomaterials while safeguarding occupants and the environment, fostering broader acceptance and adoption in construction.

Regulatory and Safety Considerations

Regulatory and safety considerations are crucial when integrating nanomaterials into fire-resistant building materials, as these substances can pose health and environmental risks if not properly managed. You must guarantee compliance with safety standards to protect workers and end-users. Proper product labeling is essential to communicate potential hazards and handling instructions. Regulatory agencies require detailed testing and documentation to approve nanomaterial use. Staying current with evolving regulations helps avoid legal issues and ensures safe application. The table below summarizes key safety aspects:

| Aspect | Requirement | Purpose |

|---|---|---|

| Product Labeling | Clear hazard information | Ensure safe handling |

| Safety Standards | Adherence to regulations | Minimize health risks |

| Testing & Documentation | Extensive safety data | Regulatory approval |

| Environmental Impact | Risk assessments | Protect ecosystems |

Additionally, understanding material safety data can help manufacturers better assess potential risks associated with nanomaterials.

Case Studies and Real-World Implementations

Real-world applications of nanomaterials in fire-resistant building materials showcase both their potential and the challenges faced during implementation. You might see nanomaterial durability tested in harsh environments, ensuring coatings withstand extreme heat and corrosion. Fire-resistant coatings infused with nanoparticles are applied to structural elements, enhancing their safety. For example:

- Nanoparticle-enhanced paints that form protective char layers during fires

- Coatings that prevent ignition on steel frameworks in commercial buildings

- Integration of nanomaterials into insulation to improve fire delay times

- Long-term performance assessments of nanomaterial-based fire-resistant panels

To ensure consistent material performance, ongoing testing and quality control are essential. These case studies highlight how nanomaterials improve fire resistance while emphasizing durability concerns. As you observe these implementations, remember that real-world success hinges on balancing nanomaterial longevity with effective fire protection.

Frequently Asked Questions

How Cost-Effective Are Nanomaterial-Enhanced Fire-Resistant Building Materials?

Nanomaterial-enhanced fire-resistant building materials can be cost-effective over time, especially when considering their durability and improved safety features. A thorough cost analysis shows that initial investments may be higher, but market adoption is growing as manufacturing costs decrease. You’ll find that these materials reduce maintenance and replacement costs, making them a financially smart choice for long-term building safety and efficiency.

What Are Potential Environmental Impacts of Nanomaterials in Construction?

Have you considered how nanomaterials impact the environment? They could pose risks through environmental toxicity if not properly managed. You should conduct a thorough lifecycle analysis to understand their full environmental footprint, from production to disposal. While nanomaterials enhance fire resistance, their potential to harm ecosystems or accumulate in soil and water remains a concern. It is crucial to balance safety benefits with environmental stewardship.

How Durable Are Nanomaterial-Based Fire-Resistant Coatings Over Time?

You’ll find that nanomaterial-based fire-resistant coatings generally offer excellent long-term performance, but their durability depends on factors like degradation mechanisms. Over time, exposure to environmental elements, heat, and mechanical wear can cause gradual deterioration. Proper formulation and application help minimize these effects, ensuring the coatings maintain their fire-resistant properties longer. Regular inspections and maintenance are also essential to maximize their lifespan and effectiveness in protecting your structures.

Can Nanomaterials Be Combined With Traditional Fire-Retardant Treatments?

Yes, you can combine nanomaterials with traditional fire-retardant treatments. This approach can create synergistic effects, enhancing fire resistance beyond what each component offers alone. Just guarantee treatment compatibility so the nanomaterials integrate well without degrading the material’s properties. Proper formulation and testing are essential to maximize benefits, ensuring the combined treatments provide durable, effective fire resistance for your building materials over time.

Are There Any Health Risks Associated With Nanomaterials During Installation?

Yes, there are health risks associated with nanomaterials during installation. You might face occupational exposure, especially if proper safety measures aren’t followed. Inhalation or skin contact can lead to potential material toxicity, affecting your health. Always wear appropriate protective gear, guarantee proper ventilation, and follow safety protocols to minimize risks. Staying cautious helps protect you from possible adverse effects linked to nanomaterials during installation.

Conclusion

As you explore nanomaterials for fire-resistant building materials, remember they’re the secret ingredients turning ordinary structures into fireproof fortresses. Like a knight’s armor, these tiny innovations offer stronger, safer, and more durable solutions. While challenges remain, embracing nanotechnology can transform your projects into resilient masterpieces. So, step into the future with confidence—because with nanomaterials, you’re building not just structures, but a safer world beneath the sky’s watchful eye.