Nanomachines are transforming oil and gas exploration and recovery by enabling you to detect subsurface formations accurately in real time, reducing risks and boosting efficiency. They navigate complex underground environments using advanced locomotion methods and swarm behaviors, helping identify hydrocarbon deposits and monitor reservoir conditions. These tiny machines improve extraction, enhance safety, and lower environmental impact. If you keep exploring, you’ll discover how innovations in nanotechnology and AI are shaping a smarter, cleaner future for the industry.

Key Takeaways

- Nanomachines enable precise underground detection, real-time reservoir monitoring, and differentiation of hydrocarbon types.

- They facilitate enhanced drilling, improved fluid flow management, and reservoir optimization for increased recovery.

- Nanotechnology improves wellbore stability, reduces formation damage, and minimizes environmental impact during extraction.

- Integration of AI and energy harvesting extends nanomachine autonomy, safety, and adaptability in harsh subsurface conditions.

- These advancements lead to safer, cleaner, and more cost-effective exploration and recovery processes in the oil and gas industry.

The Role of Nanomachines in Modern Oilfield Exploration

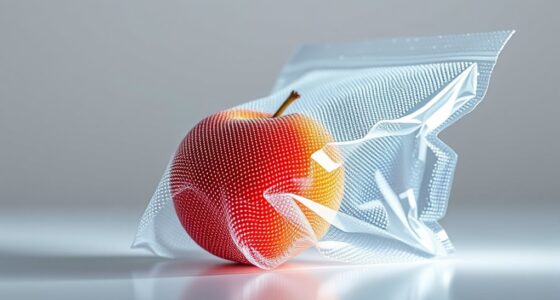

Nanomachines are revolutionizing how we explore oilfields by providing unprecedented precision and efficiency. As you deploy these tiny devices, you’ll gain the ability to detect and analyze subsurface formations at a microscopic level. They can identify oil reservoirs more accurately, reducing guesswork and minimizing drilling risks. Nanomachines can also monitor reservoir conditions in real-time, giving you instant data on pressure, temperature, and fluid composition. This detailed insight allows you to optimize extraction methods, saving time and resources. Their small size enables access to previously unreachable zones within rock formations, revealing hidden pockets of hydrocarbons. By integrating nanomachines into your exploration toolkit, you enhance your capacity to locate resources faster, safer, and with greater confidence, transforming traditional exploration into a precise science.

Techniques for Navigating Complex Subsurface Environments

You can utilize advanced microbot locomotion to maneuver through intricate underground channels with precision. Real-time subsurface imaging allows you to monitor conditions instantly, adjusting your path as needed. Together, these techniques enable efficient navigation in even the most complex subsurface environments. Incorporating high-resolution imaging technology further enhances your ability to detect and adapt to unforeseen obstacles within challenging underground terrains.

Advanced Microbot Locomotion

Traversing complex subsurface environments requires microbots to employ advanced locomotion techniques that adapt to unpredictable conditions. You might use magnetic propulsion to navigate narrow, winding fractures, or acoustic waves to move through dense, viscous fluids. Swarm behaviors allow multiple microbots to coordinate, overcoming obstacles collectively. Shape-shifting capabilities enable your microbots to squeeze through tight spaces or change orientation for better traction. Biomimicry-inspired methods mimic crawling, swimming, or crawling motions found in nature, enhancing maneuverability. You could also utilize surface tension or capillary forces for precise movement in microchannels. Additionally, employing vertical storage solutions can facilitate efficient deployment and retrieval of microbots in various operational settings. These sophisticated techniques allow microbots to traverse unpredictable terrains efficiently, ensuring they reach targets for exploration or recovery tasks without getting stuck or losing control. Mastering diverse locomotion strategies is key to effective subsurface navigation.

Real-Time Subsurface Imaging

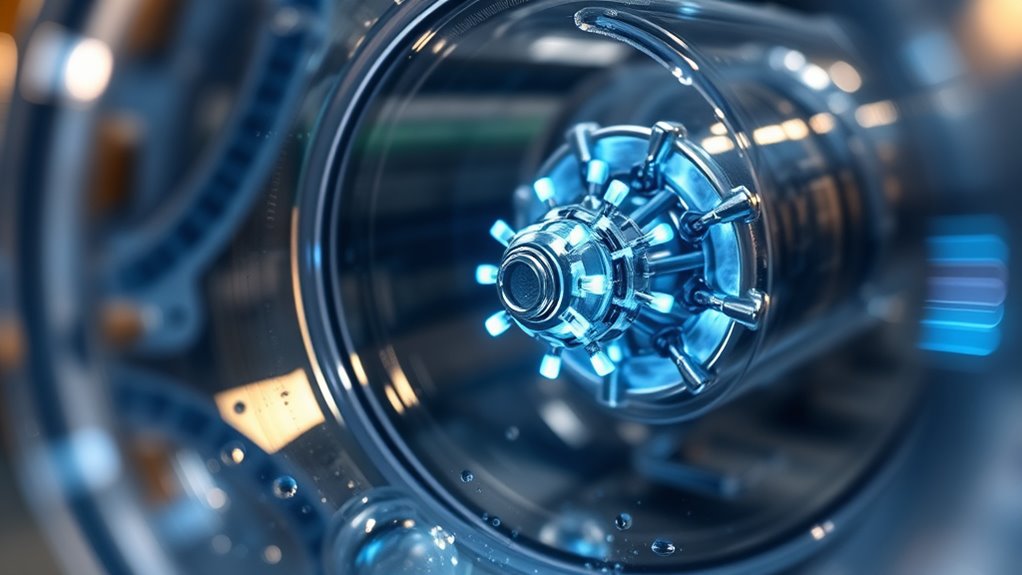

Real-time subsurface imaging is essential for steering complex underground environments with precision and confidence. By using advanced sensing technologies, you can visualize formations, detect fluid movements, and identify obstacles as they happen. Techniques like seismic tomography, electromagnetic surveys, and micro-robot sensors provide detailed, live data, allowing you to adjust drilling trajectories instantly. These methods help you avoid hazards, optimize resource extraction, and reduce non-productive time. Nanomachines play a crucial role by penetrating tight formations and transmitting high-resolution images directly to your control systems. This immediate feedback loop enables better decision-making, minimizes risks, and enhances overall efficiency. GMC tuning techniques can be integrated to customize machinery settings for optimal performance in challenging environments. With real-time imaging, you gain an extensive understanding of subsurface conditions, making complex navigation safer and more effective.

Enhancing Hydrocarbon Detection and Identification

How can nanomachines revolutionize the way you detect and identify hydrocarbons? These tiny devices can be engineered to seek out specific chemical signatures, providing highly accurate and rapid detection deep underground. By attaching sensors to nanomachines, you can achieve real-time analysis of subsurface fluids, distinguishing hydrocarbons from other substances with precision. They can navigate complex geological formations, collecting data at a granular level that traditional methods struggle to provide. Nanomachines can also differentiate between different hydrocarbon types, helping you determine quality and quantity more effectively. This targeted approach minimizes false positives and accelerates exploration timelines. Ultimately, nanomachines enhance your ability to accurately locate and identify hydrocarbons, reducing risks and increasing efficiency in exploration efforts. advancing AI technology continues to open new possibilities for precision in subsurface exploration.

Improving Extraction Efficiency With Nanotechnology

Nanotechnology can substantially boost extraction efficiency by enabling more precise control over the drilling and production processes. With nanomachines, you can optimize fluid flow within reservoirs, reducing losses and maximizing flow rates. These tiny devices can be engineered to monitor pressure, temperature, and flow conditions in real time, allowing you to make immediate adjustments. Nanoparticles can also enhance the properties of drilling fluids, improving lubrication and reducing formation damage. Additionally, nanomaterials can strengthen wellbore stability and prevent collapses, ensuring safer and more consistent extraction. By integrating nanotechnology into your operations, you gain better control over the recovery process, minimize downtime, and increase the overall yield of hydrocarbons. This precision ultimately leads to more cost-effective and efficient extraction. Furthermore, understanding the shelf life of materials can help maintain the effectiveness of nanomaterials used in extraction processes over time.

Environmental Benefits and Safety Considerations

Implementing nanomachines in oil and gas operations offers significant environmental benefits and safety advantages. They enable precise targeting, reducing the risk of spills and minimizing chemical use, which benefits ecosystems. Nanomachines can detect leaks early, preventing environmental contamination. They also improve safety by monitoring well integrity and reducing human exposure to hazardous materials. Consider the table below:

| Benefit | How it helps | Impact |

|---|---|---|

| Leak detection | Early identification of leaks | Prevents spills |

| Reduced chemical usage | Minimizes environmental footprint | Less pollution |

| Enhanced monitoring | Better safety oversight | Safer operations |

Furthermore, the integration of mindfulness techniques can enhance operational safety by promoting calm and focused decision-making among personnel.

Future Perspectives and Innovations in Nanomachine Applications

Looking ahead, the future of nanomachine applications in the oil and gas industry promises groundbreaking innovations that could revolutionize operational efficiency and environmental safety. You’ll see smarter, more autonomous nanomachines capable of real-time monitoring, precise drilling, and targeted fluid management. Advances in materials science will produce more durable, biocompatible nanodevices suited for harsh environments. Integration with artificial intelligence will enable nanomachines to adapt to changing conditions instantly, optimizing extraction and reducing risks. Additionally, innovations in energy harvesting will allow nanomachines to operate longer without external power sources. As these technologies mature, you’ll benefit from safer, cleaner extraction processes, minimized environmental impact, and reduced operational costs. The continuous evolution of nanotechnology holds the potential to transform the future landscape of oil and gas exploration and recovery. This progress in nanomaterials will further enhance the resilience and functionality of nanomachines in extreme conditions.

Frequently Asked Questions

What Are the Cost Implications of Deploying Nanomachines in Oilfields?

Deploying nanomachines in oilfields can be costly upfront due to research, development, and specialized equipment. However, you might save money long-term by improving efficiency, reducing drilling times, and minimizing environmental impact. The initial investment is high, but operational savings and increased recovery rates can offset these costs over time. Overall, while expensive initially, nanomachine deployment could lead to significant economic benefits if managed properly.

How Do Nanomachines Impact the Long-Term Sustainability of Oil Extraction?

Sure, nanomachines magically make oil extraction forever sustainable—if only. In reality, they improve efficiency, reduce environmental footprints, and help monitor reservoirs, extending extraction’s viability. You might think they’ll solve all ecological problems, but long-term sustainability still depends on responsible use and innovation. So, while nanomachines are a step forward, don’t forget they’re just tools—ultimately, your actions determine oil’s future.

Can Nanomachines Be Used to Recover Previously Inaccessible Hydrocarbons?

Yes, nanomachines can help recover previously inaccessible hydrocarbons. You can deploy them to target tight rock formations or deep reservoirs where traditional methods struggle. They work by precisely breaking down barriers or enhancing flow pathways, making it possible to extract oil that was once unreachable. This technology increases recovery rates and extends the lifespan of existing fields, offering a more efficient and sustainable approach to oil extraction.

What Are the Potential Risks of Nanomachine Failure in Subsurface Environments?

Failing nanomachines in subsurface environments are like loose cannonballs, risking environmental damage and equipment malfunction. You could face uncontrolled chemical releases, contaminating groundwater or causing blowouts. Additionally, failure might lead to costly repairs and operational delays. These tiny devices, if they malfunction, could also persist in the environment, posing long-term ecological risks. You must carefully consider these dangers and implement robust safety measures when deploying nanomachines underground.

How Do Regulatory Frameworks Address the Use of Nanotechnology in Oil and Gas?

Regulatory frameworks govern nanotechnology in oil and gas by setting safety standards, monitoring environmental impacts, and requiring thorough risk assessments. You’re expected to adhere to these rules to ensure safe development and deployment of nanomachines. Agencies like the EPA and OSHA oversee these activities, enforcing guidelines that prevent accidents and protect workers and ecosystems. Staying updated on evolving regulations helps you operate responsibly within legal and safety boundaries.

Conclusion

As you explore the world of nanomachines in oil and gas, it’s clear they’re opening new doors in exploration and recovery. These tiny marvels can navigate complex environments, boost efficiency, and improve safety, turning the tide in your favor. Embracing this technology means staying ahead of the curve and not letting opportunities slip through your fingers. With ongoing innovations, the future of nanomachines promises to be a goldmine—if you’re ready to seize the moment.