Nanomachines are tiny devices operating at a molecular level, mainly used in biomedical fields for targeted drug delivery and cellular interactions. Micro machines are larger, functioning at a microscale, often used in manufacturing and industrial applications for precise material manipulation. The main difference lies in size, applications, and manufacturing methods like self-assembly for nanomachines and microfabrication for micro machines. If you want to explore how these technologies compare and advance, you’ll find more interesting details ahead.

Key Takeaways

- Nanomachines operate at nanometer scales, mainly used in biomedical applications, while micro machines function at micrometer scales for manufacturing.

- Manufacturing nanomachines involves molecular self-assembly and DNA origami, whereas micro machines are made using MEMS microfabrication techniques.

- Nanomachines can interact with molecules and cells for targeted therapies, whereas micro machines are more durable and suited for industrial tasks.

- The size difference influences their environments: nanomachines excel in biological systems, micro machines in manufacturing environments.

- Both leverage advanced fabrication methods, with nanomachines focusing on biological interactions and micro machines on precise material manipulation.

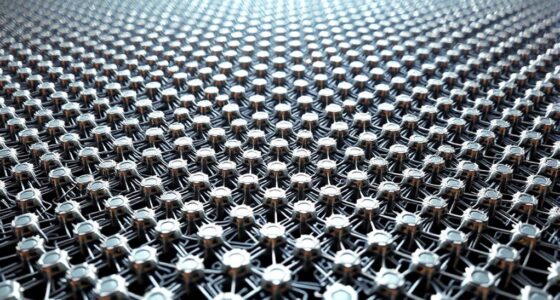

When comparing nanomachines and micro machines, it’s important to understand that they operate at vastly different scales and serve distinct purposes. Nanomachines are incredibly tiny, often measured in nanometers, while micro machines are larger, functioning at micrometer levels. This difference in size influences their applications and how they are built. You’ll find nanomachines mostly in fields like biomedical applications, where their small size allows them to navigate complex biological environments. Micro machines, on the other hand, tend to be used in manufacturing processes, where their larger size offers more robustness and easier control.

In biomedical applications, nanomachines excel because they can interact with cells, molecules, and even individual proteins. They can deliver drugs directly to targeted cells, reducing side effects and increasing treatment efficacy. For example, you might see nanomachines designed to seek out cancer cells, release medication precisely where it’s needed, and then leave without harming surrounding tissue. Their ability to operate at a cellular or molecular level makes them revolutionary for medicine. Micro machines, however, are often used in manufacturing processes that require precision at a slightly larger scale. They can assemble tiny components or manipulate materials with high accuracy, but they don’t venture into the cellular domain like nanomachines do. Their larger size makes them more suitable for tasks that demand durability and easier maintenance.

The manufacturing processes behind these two types of machines differ drastically. Nanomachines are typically built through advanced techniques like molecular self-assembly, DNA origami, or top-down lithography, which allow for extremely precise structures at the atomic level. These processes are complex and often require cleanroom environments to prevent contamination. Micro machines are generally fabricated using microelectromechanical systems (MEMS) technology, which involves etching, deposition, and other microfabrication techniques. These methods are more mature and widely used in producing sensors, actuators, and robotic components for industrial purposes.

Understanding these differences helps you appreciate the unique roles each plays. Nanomachines, with their ability to operate at the smallest scales, are revolutionizing biomedical fields, enabling targeted therapies and diagnostics. Micro machines, with their larger size and robustness, are transforming manufacturing processes, improving precision and efficiency in producing tiny components. Both types of machines harness advanced fabrication techniques suited to their scales, but their core functions and applications set them apart. As technology advances, you can expect these machines to become even more specialized, opening new frontiers in medicine and manufacturing alike. The role of innovation continues to push the boundaries of what these tiny machines can achieve.

Frequently Asked Questions

How Do Nanomachines Communicate With Each Other?

You might wonder how nanomachines communicate, and they do so through molecular signaling and wireless communication. Molecular signaling involves exchanging chemical signals at a tiny scale, allowing them to coordinate actions. Wireless communication enables nanomachines to send data through electromagnetic waves, similar to how Wi-Fi works but on a much smaller scale. This combination helps them work together efficiently, even in complex environments like the human body.

What Are the Energy Sources for Nanomachines in Medical Applications?

You’ll find nanomachines in medical applications are powered mainly by biological energy and chemical power. They harness the body’s natural processes, like glucose or other molecules, to generate energy, ensuring they operate efficiently within your body. This approach minimizes the need for external power sources, making nanomachines safer and more effective for targeted treatments, drug delivery, or diagnostics by seamlessly integrating with your biological systems.

Can Micro Machines Operate in Extreme Environmental Conditions?

Micro machines can operate in some extreme environmental conditions, but their environmental resilience depends on their design and materials. You should recognize that they face operational limitations in environments with high temperatures, strong magnetic fields, or corrosive chemicals, which can hinder their functionality. While advancements have improved their durability, these limitations mean you need to carefully consider the specific conditions to ensure effective performance in challenging environments.

What Are the Manufacturing Challenges for Nanomachines?

You face significant manufacturing challenges with nanomachines, as they require precision at scales smaller than 100 nanometers. Scaling difficulties make it tough to produce these devices consistently, and material limitations hinder their development. You must develop innovative techniques to manipulate materials at such tiny sizes, ensuring functionality and durability. Overcoming these hurdles is vital for advancing nanotechnology and enabling their potential in medicine, electronics, and environmental applications.

How Do Safety Concerns Differ Between Nanomachines and Micro Machines?

You should consider that safety concerns for nanomachines involve ethical implications and regulatory challenges, since their tiny size could lead to unintended health risks or environmental impacts. Micro machines, being larger, pose fewer unknown risks but still require safety protocols. As you develop or oversee these technologies, make certain you address ethical concerns and navigate regulatory hurdles to protect users, the environment, and society at large.

Conclusion

As you picture tiny nanomachines weaving through your bloodstream like shimmering threads, and micro machines bustling like busy cities, you realize both hold incredible power. Nanomachines drift silently, repairing and transforming at a cellular level, while micro machines march with purpose across larger landscapes. Together, they paint a vivid future where technology is almost alive, seamlessly blending into your world. It’s a breathtaking dance of innovation, promising a tomorrow where the smallest creations make the biggest differences.