Nanocoatings are invisible layers made from nanoparticles that defend surfaces by repelling water, oils, dirt, and microbes. They enhance durability, resist scratches, and prevent corrosion, making objects last longer across industries like automotive, electronics, and healthcare. These smart, eco-friendly coatings can also respond to environmental changes, self-repair, and reduce cleaning needs. To discover how this cutting-edge technology is transforming everyday protection, explore the details that follow.

Key Takeaways

- Nanocoatings form invisible, durable layers that protect surfaces from water, oils, dirt, microbes, and environmental damage.

- They incorporate nanoparticles like titanium dioxide and graphene for UV protection, antibacterial properties, and increased surface hardness.

- These coatings enable self-cleaning, scratch resistance, and anti-fingerprint features, reducing cleaning and maintenance needs.

- Widely used in electronics, automotive, aerospace, and healthcare to extend material lifespan and enhance safety.

- Future advancements include smart, self-healing, and eco-friendly nanocoatings that adapt to environmental conditions and promote sustainability.

What Are Nanocoatings and How Do They Work?

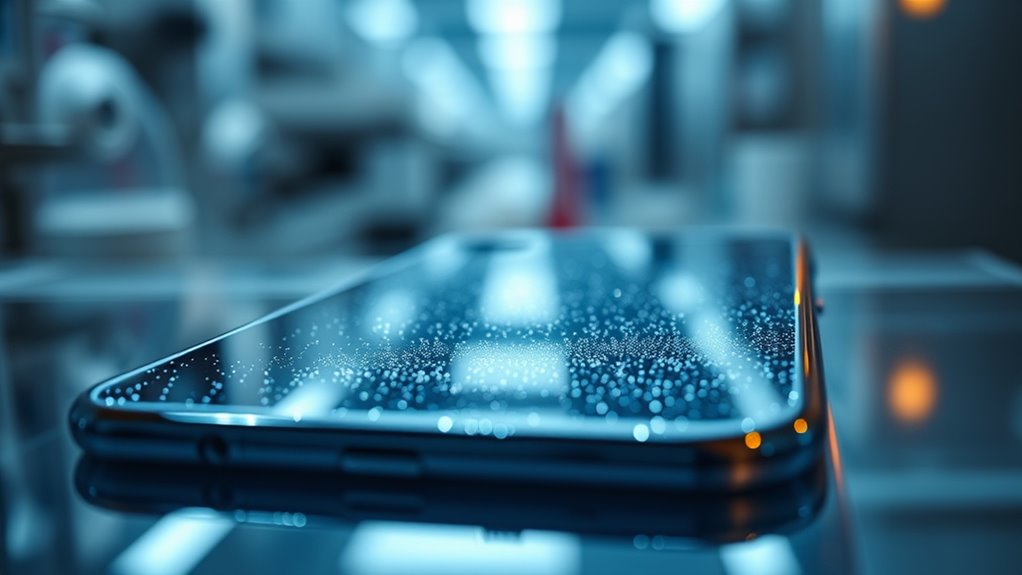

Have you ever wondered how surfaces can stay cleaner, stronger, and more resistant with just a tiny layer? That’s the magic of nanocoatings. These ultra-thin layers, made from nanoparticles just 1 to 100 nanometers thick, form a seamless shield over surfaces. Because they’re so small, they’re invisible to the naked eye but pack a punch in protection. Nanocoatings work by creating a dense network of chemical bonds with the surface, sealing it from water, oils, dirt, and microbes. They combine nanoparticles like titanium dioxide or graphene with advanced polymer systems, enhancing durability and resistance. When applied, they form a protective layer that resists scratches, repels liquids, prevents corrosion, and sometimes even responds to environmental stimuli, making surfaces smarter and more resilient. This technology exemplifies how innovations in nanotechnology can contribute to more sustainable and energy-efficient cloud solutions by reducing the need for frequent cleaning and maintenance. Additionally, their ability to improve surface properties aligns with the goal of creating more durable and sustainable materials in various industries.

Key Properties That Make Nanocoatings Unique

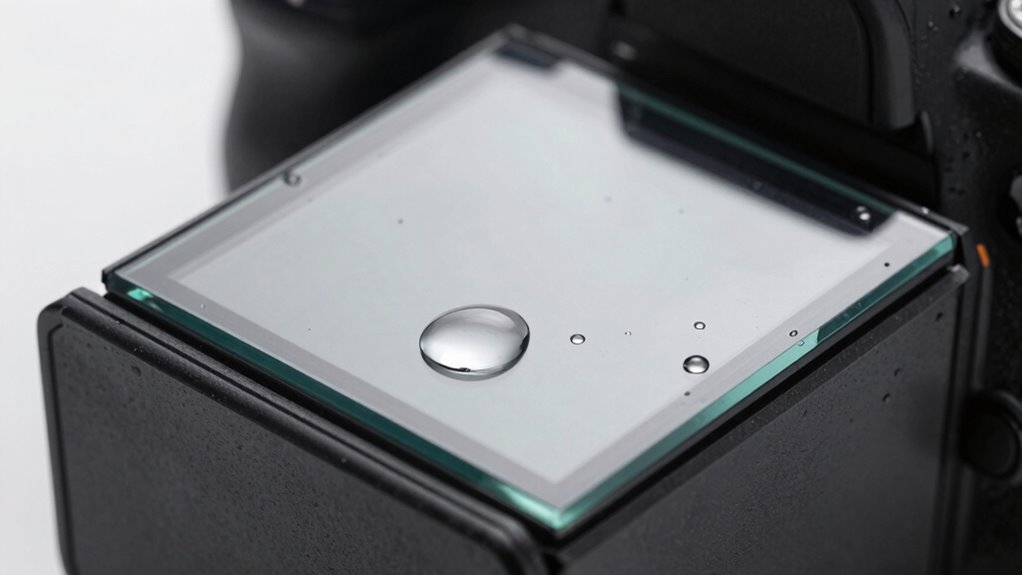

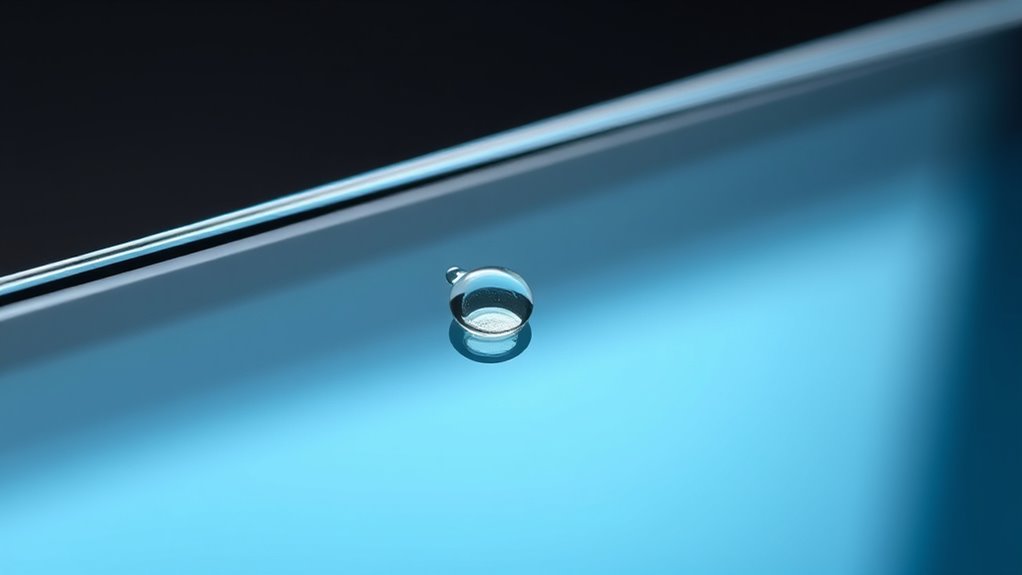

What sets nanocoatings apart are their remarkable properties that deliver superior surface protection and functionality. Their hydrophobic and oleophobic nature means they repel water and oils, keeping surfaces clean and dry. They also provide bacterial resistance, UV scattering, and high hardness, making surfaces more durable. Nanocoatings can enable self-cleaning, scratch resistance, and anti-fingerprint features, reducing maintenance needs. They form dense chemical bonds with surfaces, creating a seamless, protective layer that resists corrosion and micro-abrasion. Many nanocoatings also offer thermal resistance and antifogging capabilities. By dispersing nanoparticles within a matrix, they enhance surface durability while maintaining invisibility. These properties make nanocoatings uniquely versatile, providing high-performance protection across various environments without altering the appearance or functionality of the underlying material. Smart surface technologies further expand their potential applications, integrating seamlessly with connected devices and innovative home environments. The nanoparticle dispersion within coatings ensures consistent performance and durability over time, even under harsh conditions. Additionally, the development of environmentally friendly nanocoatings aims to reduce ecological impact while maintaining high efficiency. Advances in coating application methods also improve the ease and cost-effectiveness of deploying nanocoatings across different industries. Furthermore, understanding the biocompatibility of nanomaterials is crucial for expanding their use in health-related applications.

Diverse Applications of Nanocoatings in Modern Industries

Nanocoatings find widespread use across modern industries due to their ability to enhance surface performance and durability. You’ll see their impact everywhere, from protecting electronics to improving medical devices. Their ability to provide long-lasting protection ensures surfaces remain resistant to environmental factors over time. In the medical field, they provide antibacterial surfaces, making equipment safer and more hygienic. In transportation, nanocoatings improve corrosion resistance, reduce maintenance, and enhance safety for vehicles and aircraft. Additionally, these coatings can contribute to energy efficiency by reducing the need for frequent repairs and replacements. These coatings also find their way into industrial manufacturing, safeguarding machinery and tools against wear. Their versatility means you’ll encounter nanocoatings in everyday items, from smartphone screens to automotive parts. By offering protection, longevity, and cleanliness, nanocoatings are reshaping how surfaces perform across industries, often leveraging advanced nanotechnology to achieve these benefits. Furthermore, ongoing research into material enhancement continues to expand their potential applications across diverse sectors. Incorporating water-repellent properties through hydrophobic coatings is another area where nanocoatings are making significant advancements, especially for outdoor and marine applications.

Materials and Nanoparticles Used in Coating Formulations

Materials and nanoparticles form the foundation of effective nanocoatings, enabling their unique properties and functionalities. You’ll find common nanoparticles like zinc oxide, titanium dioxide, silica dioxide, graphene, and carbon nanotubes, each offering specific benefits. These particles are incorporated into coatings to provide UV protection, antibacterial properties, or enhanced durability. Some formulations use zirconium dioxide or boehmite in UV-curable systems for increased resistance. Hybrid products combine nanoparticles with high-performance binders, forming strong chemical bonds that improve adhesion and longevity. You might also encounter aerogels, silica, or titanium dioxide in applications demanding high durability. Whether applied as liquids or solids, these nanomaterials create dense, protective layers that repel water, oils, and dirt, making surfaces more resistant to wear, corrosion, and environmental damage. Understanding nanocoatings can further enhance their application and performance in various industries. Additionally, the incorporation of nanoparticle technology allows for tailored functionalities suited to specific environmental challenges. The development of advanced nanomaterials continues to expand the potential applications of nanocoatings across diverse sectors, leveraging innovative material science to meet evolving needs.

Benefits of Using Nanocoatings for Surfaces and Materials

Nanocoatings substantially improve surface durability and resistance, making materials more resistant to scratches, corrosion, and environmental damage. They also offer environmental and maintenance benefits by reducing the need for frequent cleaning and chemical use. As a result, nanocoatings help extend the lifespan of your materials, saving you time and costs over the long term. Additionally, nanocoatings enhance surface protection by forming a thin, durable barrier that shields surfaces from everyday wear and tear. Incorporating nanocoatings can also contribute to safety and reliability by preventing degradation that might compromise structural integrity. Furthermore, advances in nanotechnology continue to expand the potential applications and effectiveness of these coatings across various industries. The ability of nanocoatings to create protective barriers is a key factor in their growing adoption across sectors such as healthcare, automotive, and electronics. These innovations are driven by ongoing research and developments in material science, which enhance the performance and versatility of nanocoatings.

Enhanced Durability and Resistance

By applying nanocoatings, surfaces gain markedly enhanced durability and resistance to environmental stresses. These ultra-thin layers protect against wear, corrosion, and scratches, extending the lifespan of materials. You’ll notice improved performance in demanding conditions, saving you maintenance time and costs. Nanocoatings provide:

- Superior resistance to water, oils, and dirt, keeping surfaces cleaner and reducing cleaning efforts. This surface protection is achieved through advanced nanotechnology, creating a barrier that adapts to various environmental challenges. Additionally, the nanomaterial composition contributes to the coatings’ effectiveness in diverse scenarios.

- Enhanced scratch and abrasion resistance, maintaining surface integrity and appearance over time. Incorporating nanomaterials into coatings enhances their ability to withstand physical impacts. This coating durability ensures long-lasting aesthetic appeal.

- Exceptional corrosion protection, preventing rust and deterioration in harsh environments. This corrosion resistance is crucial for outdoor and industrial applications where exposure to moisture and chemicals is frequent.

This combination of properties guarantees your surfaces withstand environmental challenges, from UV exposure to chemical spills. As a result, nanocoatings offer a durable shield that preserves functionality and aesthetics, making them ideal for critical applications across industries.

Environmental and Maintenance Benefits

Applying nanocoatings not only boosts surface durability but also offers significant environmental and maintenance advantages. These ultra-thin layers make surfaces resistant to water, oils, and dirt, which means you’ll spend less time cleaning and reapplying protective layers. Because nanocoatings reduce the need for harsh chemicals and frequent upkeep, they help lower your ecological footprint. Their self-cleaning and anti-fingerprint properties keep surfaces cleaner longer, minimizing water and cleaning product use. Additionally, nanocoatings’ corrosion and scratch resistance prevent premature replacement of materials, reducing waste. Their ability to inhibit microbial growth also means fewer disinfectants are necessary, supporting healthier environments. Overall, nanocoatings streamline maintenance routines, extend surface life, and contribute to greener, more sustainable practices in everyday applications.

Extended Material Lifespan

Using nanocoatings on surfaces can substantially extend their lifespan by providing a durable, protective barrier against environmental damage. This barrier shields materials from corrosion, scratches, and chemical wear, helping them stay functional longer.

- Resists corrosion and oxidation, preventing material degradation in harsh environments.

- Stops scratches and abrasions, maintaining surface integrity and appearance.

- Reduces maintenance needs, lowering replacement costs and downtime over time.

Cutting-Edge Advancements in Nanocoating Technologies

Recent advances in nanocoating technologies focus on smart responsive systems that react to environmental stimuli, offering tailored protection. These coatings are designed to enhance durability by resisting scratches, corrosion, and wear far beyond traditional options. As you explore these innovations, you’ll see how they provide adaptive, long-lasting solutions for a wide range of surfaces.

Smart Responsive Coatings

Smart responsive coatings represent a breakthrough in nanocoating technology by enabling surfaces to react dynamically to environmental stimuli. These coatings can sense changes like temperature, pH, or chemical presence and respond accordingly. This adaptability offers enhanced protection and functionality. For example:

- They can switch from hydrophobic to hydrophilic states, allowing surfaces to repel water or absorb moisture as needed.

- They can release anti-microbial agents when detecting bacteria or other microorganisms.

- They adjust their optical properties in response to light or UV exposure, providing self-cleaning or UV protection.

Enhanced Durability Features

Advancements in nanocoating technologies have considerably boosted durability by creating ultra-robust, chemically bonded layers that withstand harsh environments. These coatings form dense, molecular-level bonds with surfaces, making them highly resistant to scratches, wear, and corrosion. Incorporating nanoparticles like silica, titanium dioxide, or graphene enhances their hardness and protective qualities, extending the lifespan of underlying materials. Modern nanocoatings also feature self-healing properties, automatically repairing minor damages and scratches. They excel at resisting UV degradation, extreme temperatures, and chemical exposure, ensuring long-term performance. Additionally, smart nanocoatings respond to environmental stimuli, activating protective mechanisms when needed. All these advancements make nanocoatings ideal for demanding applications, from automotive finishes to aerospace components, providing unmatched durability that reduces maintenance and replacement costs over time.

Environmental and Maintenance Advantages of Nanocoatings

Nanocoatings offer significant environmental and maintenance benefits by reducing the need for chemical cleaners, water, and repeated repairs. You’ll find that surfaces stay cleaner longer, thanks to their self-cleaning properties, which repel dirt and grime. This means fewer cleaning agents enter our ecosystems, lowering chemical runoff. Additionally, nanocoatings extend the lifespan of materials, decreasing the frequency of repairs and replacements. Here’s how they help:

- They cut down on cleaning chemicals and water use, making maintenance eco-friendlier.

- Their durability reduces the need for frequent repairs, saving resources.

- They prevent corrosion and damage, helping materials last longer and reducing waste.

Future Trends and Innovations in the Nanocoating Sector

Have you ever wondered what the future holds for nanocoatings? The sector is rapidly evolving, with innovations focused on smart, responsive, and multifunctional surfaces. Expect coatings that adapt to environmental changes, such as self-healing materials that repair scratches and damage automatically. Researchers are developing nanocoatings that react to pollutants, neutralizing VOCs or harmful microbes in real-time. Integration with renewable energy is also advancing, with coatings that maximize solar panel efficiency by preventing dirt buildup. Additionally, you’ll see more tailored nanocoatings designed for specific industries, like aerospace or medical tech, offering enhanced protection and durability. As nanotechnology progresses, you’ll likely benefit from more sustainable, eco-friendly options that extend lifespan, reduce maintenance, and deliver smarter, more adaptive surface protections.

Frequently Asked Questions

How Long Do Nanocoatings Typically Last on Different Surfaces?

Nanocoatings typically last between 3 to 10 years, depending on the surface and environmental factors. You can expect longer durability on less exposed surfaces like indoor electronics, while outdoor applications like automotive or building exteriors may need reapplication sooner due to weather, UV exposure, and wear. Proper maintenance, cleaning, and avoiding harsh chemicals can help extend their lifespan, ensuring continued protection and performance.

Are Nanocoatings Safe for Human Health and the Environment?

Imagine a shield so fine it’s invisible yet powerful, like a whisper of protection. Nanocoatings are generally safe for you and the environment when applied correctly, as they contain non-toxic materials and are designed to minimize risks. However, you should be cautious during application to avoid inhaling nanoparticles. Ongoing research guarantees these coatings stay safe, so you can enjoy their benefits without worry.

Can Nanocoatings Be Removed or Repaired if Damaged?

Yes, you can remove or repair nanocoatings if they’re damaged. For removal, you might need specialized cleaning agents or mechanical methods like sanding, depending on the surface and coating type. Repair typically involves reapplying a fresh layer of nanocoating or using touch-up products designed for that material. It’s best to follow manufacturer instructions to guarantee proper repair or removal, maintaining surface protection and performance.

Do Nanocoatings Affect the Appearance or Transparency of Surfaces?

Nanocoatings generally don’t affect the appearance or transparency of surfaces because they’re ultra-thin and invisible. When applied, they form a microscopic layer that maintains the surface’s original look, whether it’s glass, plastic, or metal. You won’t notice any change in clarity or color. This transparency makes nanocoatings ideal for screens, lenses, and other surfaces where appearance is important, while still providing enhanced protection and functionality.

What Are the Costs Associated With Applying Nanocoatings at Scale?

Applying nanocoatings at scale can be costly upfront due to specialized materials and equipment. You’ll need to invest in high-precision applicators and quality control systems. Additionally, labor costs may be higher because of the expertise required for even, consistent coatings. However, over time, these costs are offset by the benefits, such as increased durability, reduced maintenance, and longer lifespan of surfaces, which save you money in the long run.

Conclusion

Nanocoatings are like a futuristic armor, silently safeguarding your environment with invisible strength. As technology evolves, you’ll see these coatings becoming more adaptable and eco-friendly, much like the legendary phoenix rising anew. Staying ahead of the curve, you can harness these innovations to protect and enhance surfaces seamlessly. Embrace this invisible tech now, because in a world where even the smallest details matter, nanocoatings are truly the unsung heroes of tomorrow.