Nanotech is revolutionizing printable solar cells by enabling ultra-thin, flexible, and lightweight designs that can be easily produced at scale. Advanced fabrication methods like inkjet and slot-die printing reduce costs and waste, making solar energy more affordable. Incorporating nanomaterials such as quantum dots and perovskites boosts efficiency and performance. These innovations lower the barrier to widespread adoption, and exploring further reveals how this technology is shaping a greener, more accessible energy future.

Key Takeaways

- Nanomaterials like quantum dots and perovskites enhance light absorption and electron transfer, increasing solar cell efficiency.

- Printable inks with nanomaterials enable scalable, low-cost manufacturing of flexible, lightweight solar panels.

- Advanced fabrication techniques reduce material waste and energy use, lowering production costs.

- Thin-film nanomaterials maximize energy absorption while minimizing light loss, boosting overall power output.

- Increased manufacturing scalability drives down prices, making solar energy more affordable and accessible worldwide.

The Ultraflexible Advantage of Printable Solar Cells

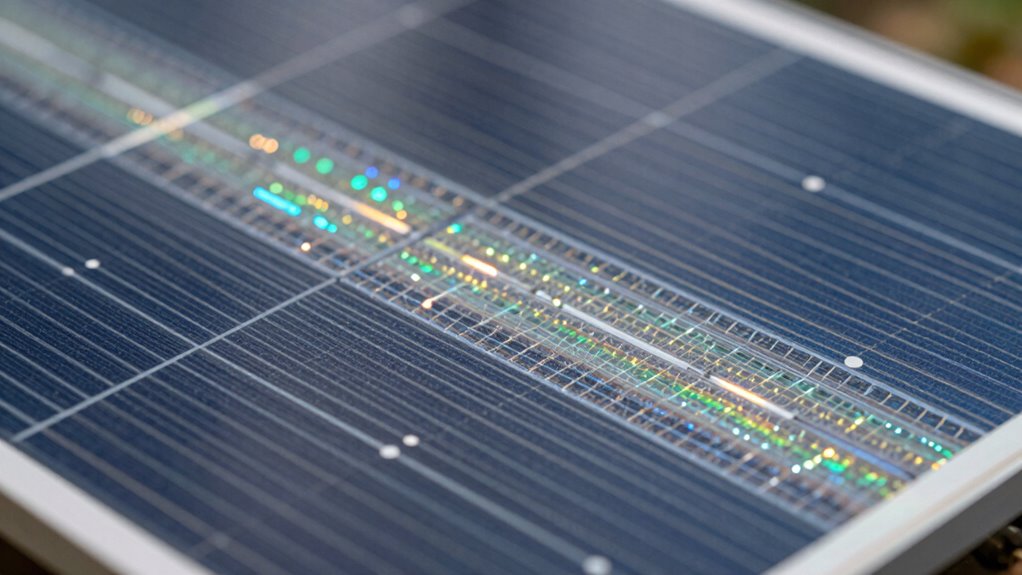

Because they are so ultrathin and lightweight, printable solar cells offer unmatched flexibility for a variety of surfaces. Their thickness measures just 15 microns for freestanding modules, making them incredibly easy to bend, stretch, and conform to different shapes. They weigh 100 times less than traditional panels, so you can apply them to fabrics, windows, and even curved structures without adding significant weight. With a thickness limited to 3 microns during fabrication, these cells can be integrated into materials like paper or fabric, creating versatile, portable power sources. Their paper-thin design enables you to attach solar power to almost any surface—clothing, car surfaces, or building facades—without sacrificing durability or performance. This flexibility facilitates new possibilities for renewable energy everywhere you go. Additionally, their ease of installation makes them accessible for DIY projects and rapid deployment in diverse environments. Moreover, their material compatibility ensures they can be seamlessly incorporated into existing products and structures, expanding their potential applications. Advances in nanotechnology continue to enhance the efficiency and durability of printable solar cells, and ongoing research in material science promises even greater improvements in performance and lifespan. Furthermore, innovations in fabrication techniques are helping to lower production costs, making these solar solutions more affordable for widespread use.

Cutting-Edge Fabrication Techniques in Nanotech Solar Power

Advancements in fabrication techniques are driving the development of truly innovative nanotech solar cells. You now use printable electronic inks infused with nanomaterials, enabling precise layer deposition on flexible substrates. Techniques like slot-die coating and screen printing streamline production, reducing waste and costs. Inkjet printing allows for intricate patterns, especially with perovskite solar cells, while nanoparticle inks create efficient CIGS layers. These methods produce ultrathin, lightweight modules that can conform to any surface. The table below highlights key fabrication approaches and their impact:

| Technique | Material Focus | Benefit |

|---|---|---|

| Slot-die coating | Releasable substrates | Fast, scalable layer application |

| Screen printing | Electrodes, conductive layers | Cost-effective, high throughput |

| Inkjet printing | Perovskite layers | Precise, low waste |

| Nanoparticle inks | CIGS absorbers | Enhanced efficiency |

Advances in nanotechnology are enabling the creation of more efficient and affordable solar energy solutions. Additionally, ongoing research aims to improve the durability of these nanomaterial-based cells for long-term use. For example, manufacturing scalability is crucial for widespread adoption of these innovative solar technologies.

Boosting Efficiency: How Thin Films Maximize Energy Output

Have you ever wondered how ultra-thin solar films achieve such high energy outputs? The secret lies in their innovative design and materials. These films are just a few microns thick, which minimizes light loss and allows for more efficient light absorption. Thin layers of nanomaterials, like quantum dots and perovskites, enhance electron transfer and boost conversion rates. Their lightweight and flexible nature enable them to cover more surface area, capturing sunlight from multiple angles. Additionally, stacking multiple thin layers creates tandem cells, capturing a broader spectrum of sunlight. Advanced fabrication techniques ensure minimal energy wastage, maximizing power output per unit weight. Furthermore, vetted quality control during manufacturing guarantees consistent performance and longevity. The development of nanomaterials has revolutionized the field by enabling these enhancements. By optimizing thickness and material properties, thin films push the boundaries of efficiency, making solar energy more powerful, versatile, and cost-effective. Additionally, ongoing research into material stability is crucial for ensuring long-term durability and sustainable use of these advanced solar cells. Continuous innovations in fabrication methods are also expanding the potential applications of these flexible solar solutions.

Innovative layering techniques further improve light capture and energy conversion efficiency.

Innovative Materials Powering Next-Generation Solar Devices

Innovative materials are transforming how next-generation solar devices capture and convert sunlight. You’ll find ultrathin, lightweight components that can be applied to almost any surface, from fabrics to windows. These materials include nanomaterial inks, perovskites, and quantum dots, which enable flexible, high-performance solar cells. Their unique properties allow for increased power output with less weight and material waste. The table below highlights key innovations:

| Material Type | Functionality | Advantage |

|---|---|---|

| Nanomaterials | Ink-based layers | Cost-effective, scalable production |

| Perovskites | Light absorption | Flexible, high efficiency |

| Quantum Dots | Electron transfer | Enhanced light conversion |

These advanced materials are paving the way for versatile, affordable solar solutions. Additionally, the development of nanotechnology in solar materials is driving new breakthroughs in efficiency and manufacturing, which can lead to cost reduction and wider adoption of solar energy systems. Incorporating these innovative nanomaterials also opens up possibilities for energy storage integration, further improving the practicality of solar power. The ongoing research into material durability ensures these next-generation devices can operate reliably over extended periods, making them more practical for everyday use. Moreover, advances in scalable manufacturing techniques are expected to accelerate the commercialization of these technologies, making solar energy more accessible worldwide.

Cost-Effective Production Transforming the Solar Market

Printable solar cell production is becoming more cost-effective thanks to scalable printing techniques that reduce material waste and energy use. These methods streamline manufacturing, cutting costs and making solar energy more accessible. By using techniques like slot-die coating, screen printing, and inkjet printing, you can produce thinner, lighter, and more flexible solar cells efficiently. This approach also enables rapid production cycles, which further lowers overall costs. This reduces the need for expensive raw materials and minimizes waste. Additionally, low-energy processing methods lower overall production expenses. The lightweight nature of these cells simplifies installation and expands application possibilities. Manufacturing scalability plays a crucial role in driving down prices and increasing adoption. As production scales up, prices are expected to drop further, breaking down barriers to large-scale manufacturing. This transformation makes solar energy more affordable and accelerates its adoption worldwide. Regular practice and visual cues can help in mastering new techniques, similar to consistent feedback in speech therapy that ensures continuous improvement. Moreover, incorporating ventilation considerations during manufacturing can enhance cell performance and longevity. Emphasizing sustainable manufacturing practices can further reduce environmental impact and improve overall efficiency.

Frequently Asked Questions

How Durable Are These Ultrathin Printable Solar Cells in Harsh Environments?

You’ll find that these ultrathin printable solar cells are quite durable in harsh environments. Their flexible, lightweight design allows them to withstand bending, vibrations, and temperature fluctuations. Using nanomaterials enhances their resilience against weathering, UV exposure, and mechanical stress. Plus, their ability to adhere to various surfaces makes them adaptable for outdoor, industrial, and even mobile applications, ensuring reliable performance over time despite challenging conditions.

Can Printable Solar Cells Be Recycled or Reused Effectively?

You can recycle printable solar cells effectively by carefully removing and reprocessing their nanomaterial inks. For example, imagine refurbishing used cells on building facades by washing off old inks and reprinting fresh layers, extending their lifespan. This process helps reduce waste and costs, making them more sustainable. As technology advances, improved recycling techniques will make reusing these ultra-thin, flexible cells even easier and more efficient.

What Is the Lifespan of These Nanotech-Based Solar Modules?

Your nanotech-based solar modules typically last between 10 to 15 years, depending on usage and environmental conditions. They’re designed with durable materials like CIGS and perovskite, which can withstand sunlight and weather. While they may degrade faster than traditional panels, ongoing advancements in material stability and protective coatings aim to extend their lifespan. Proper maintenance and installation can also help maximize their longevity and efficiency over time.

Are There Health or Safety Concerns With Nanomaterials in Production?

You should be aware that nanomaterials in production can pose health and safety risks, like tiny pirates lurking in your workspace. Inhalation or skin contact may cause irritation or long-term health issues if proper precautions aren’t taken. That’s why manufacturers use protective gear, ventilation, and strict handling procedures. While advances make production safer, ongoing research aims to eliminate these risks entirely, ensuring these innovative solar cells are both powerful and safe.

How Scalable Is the Manufacturing Process for Global Deployment?

You can scale the manufacturing process easily for global deployment because it uses scalable printing techniques like slot-die coating, screen printing, and inkjet printing. These methods reduce waste, cut costs, and can be expanded rapidly. Plus, the lightweight, flexible nature of these solar cells allows for versatile applications worldwide, from fabrics to rooftops. As production ramps up, prices will drop, making widespread adoption more feasible and efficient.

Conclusion

So, while nanotech makes printing solar cells cheaper and more flexible, don’t forget—costs may drop, but the true challenge lies in ensuring everyone benefits. It’s ironic how technology promises an energy revolution, yet affordability might still leave some behind. As you embrace these innovations, remember that accessible, sustainable energy isn’t just about cheap materials—it’s about making a real difference for all. Because even with tiny tech, big change remains the ultimate goal.