Quantum dots are tiny semiconductor particles that produce bright, tunable light due to quantum confinement effects. Their size determines their electrical and optical properties, making them ideal for displays, solar cells, and biomedical imaging. Advanced synthesis methods and surface modifications enhance their stability and performance. These remarkable particles are revolutionizing technology, offering a bright future in various industries. Keep exploring to discover how their unique features continue to shape innovation and everyday life.

Key Takeaways

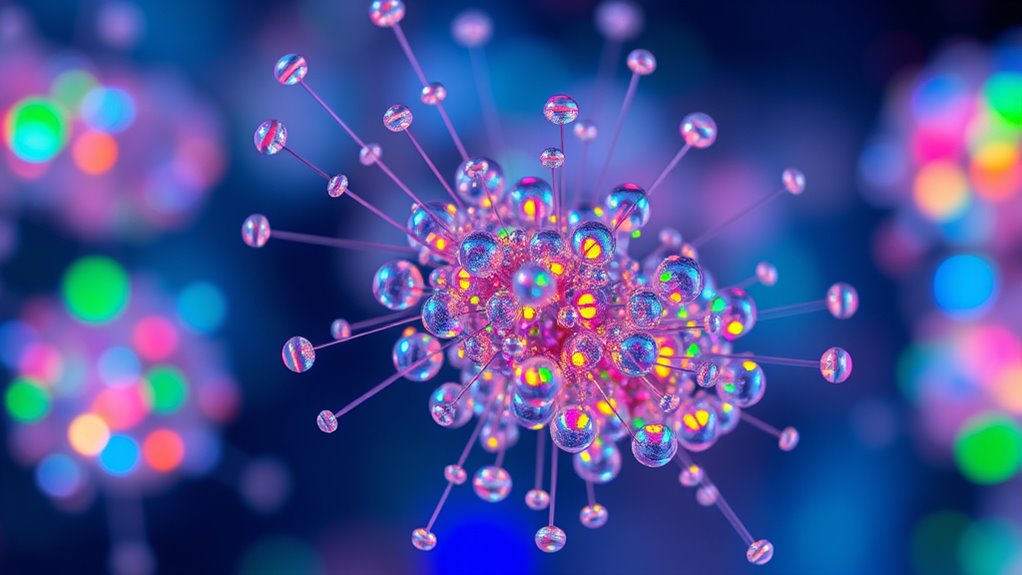

- Quantum dots are tiny semiconductor particles with size-dependent optical and electronic properties, acting as artificial atoms.

- Their tunable emission wavelengths and high brightness make them ideal for advanced displays and biomedical imaging.

- Precise synthesis and surface functionalization enable customization for applications in solar energy, sensors, and lighting.

- Their stability, narrow emission spectra, and enhanced electron transfer improve device performance and longevity.

- Quantum dots are transforming industries by enabling brighter, more efficient, and highly precise technologies across multiple fields.

What Are Quantum Dots and How Do They Work?

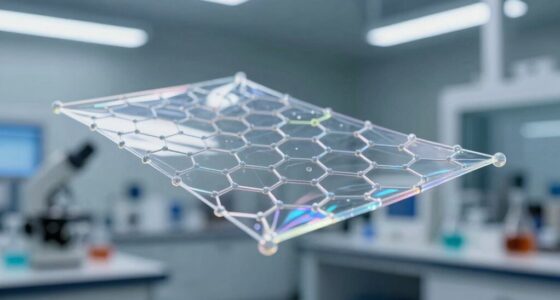

Quantum dots are tiny semiconductor particles measuring just 2 to 10 nanometers across, and they work by confining electrons in all three dimensions through quantum mechanical effects. This confinement creates discrete energy levels similar to those found in individual atoms, making quantum dots behave like artificial atoms. Because of their small size, their electronic and optical properties depend on their dimensions, allowing you to tune their behavior by adjusting their size. When excited by light or electricity, electrons jump to higher energy states and then fall back, releasing energy as visible light. The specific wavelength of this light depends on the quantum dot’s size, enabling precise control over color. This size-dependent property makes quantum dots highly versatile for various applications, from displays to biomedical imaging. Quantum confinement is the key phenomenon that allows these tiny particles to have such customizable optical properties. Additionally, advances in nanotechnology are enabling the production of more uniform and efficient quantum dots, broadening their potential uses.

The Science Behind Quantum Confinement

The key to understanding how quantum dots manipulate light lies in the phenomenon known as quantum confinement. This effect occurs when electrons are trapped in all three dimensions within tiny nanocrystals, creating discrete energy levels similar to atoms. As the size of the quantum dot decreases, the energy gap widens, shifting emitted light toward the blue spectrum; larger dots emit red light. This size-dependent behavior results from the bandgap changing with particle dimensions. To grasp this better:

- Electrons are confined in three dimensions

- Smaller dots produce higher-energy blue light

- Larger dots emit lower-energy red light

- Discrete energy levels resemble artificial atoms

- The density of states becomes delta-shaped

- The color spectrum produced by quantum dots can be precisely tuned by adjusting their size

- The quantum confinement effect is essential for the development of highly efficient light-emitting devices and displays.

- Understanding the size-dependent emission allows engineers to customize quantum dot properties for specific applications.

- Researchers are continuously exploring new material compositions to enhance quantum dot performance and stability.

- Advances in nanocrystal synthesis techniques enable more consistent and scalable production of quantum dots with tailored properties.

This confinement enables quantum dots to produce precise, tunable colors for various applications.

Different Types and Structures of Quantum Dots

Different types and structures of quantum dots are designed to optimize their optical and electronic properties for various applications. You’ll find core-only quantum dots, where the semiconductor nanocrystal is uniform, offering straightforward emission. Core-shell structures, like CdSe/ZnS, surround a core with a different material to boost quantum yield and stability. Inverse Type I dots feature a smaller bandgap shell that delocalizes charge carriers, useful for charge transport and quantum computing. You can also engineer their shape—spherical, rod-like, or pyramidal—to influence light absorption and emission. These variations allow you to tailor quantum dots for specific tasks, whether in displays, solar cells, or biological sensors. Each type’s unique structure impacts how electrons behave, enabling precise control over their optical and electronic characteristics. Structural engineering of quantum dots further enhances their performance for targeted applications, allowing for customized functionalities based on their shape and composition. Additionally, ongoing research into quantum dot synthesis techniques continues to expand their potential uses and improve their properties. Advances in surface chemistry modifications also contribute significantly to optimizing their stability and compatibility in different environments.

How Quantum Dots Are Made: Synthesis Techniques

You can create quantum dots using colloidal synthesis, which allows precise control over their size and properties. Advanced fabrication methods like molecular beam epitaxy and X-ray lithography also produce high-quality nanocrystals with specific structures. Exploring these techniques helps you understand how to tailor quantum dots for various applications.

Colloidal Synthesis Processes

Colloidal synthesis is a widely used method for creating quantum dots with precise control over size and composition. You typically start by mixing metal precursors with surfactants and solvents, then heating the mixture to induce nucleation and growth. As the particles form, temperature, time, and reagent concentration dictate size and uniformity. This process allows you to fine-tune optical properties for specific applications.

You’ll find that colloidal synthesis offers:

- Precise size control by adjusting reaction parameters

- High monodispersity for uniform emission

- Compatibility with various semiconductor materials

- Scalability for large-scale production

- Surface functionalization for stability and targeting

This method’s versatility makes it a cornerstone in quantum dot manufacturing, enabling bright, tunable nanocrystals for multiple tech fields.

Advanced Fabrication Methods

Advanced fabrication methods for quantum dots encompass a range of techniques beyond colloidal synthesis, each offering unique advantages for controlling size, composition, and electronic properties. Molecular beam epitaxy allows atom-by-atom crystal growth, ensuring precise size and structure. Ion implantation introduces ions into substrates for tailored features. X-ray lithography enables atomic-scale patterning, creating intricate designs. These methods provide better integration into devices and improved uniformity.

| Method | Key Benefit | Typical Use Case |

|---|---|---|

| Molecular Beam Epitaxy | Precise size and composition | High-quality layered structures |

| Ion Implantation | Custom doping | Semiconductor modification |

| X-ray Lithography | Atomic-scale patterning | Nanostructure fabrication |

| Colloidal Synthesis | Precise nanocrystal control | Solution-based applications |

| Biological Methods | Eco-friendly, biocompatible | Medical imaging |

Unique Optical and Electronic Properties

What makes quantum dots truly remarkable are their unique optical and electronic properties, which stem from their nanoscale size and quantum confinement effects. Because of their tiny dimensions, you can tune their light emission by simply adjusting their size, producing vibrant colors across the visible spectrum. They also exhibit high quantum yields, making them brighter and more efficient than traditional dyes. Their narrow emission spectra ensure pure, intense colors, ideal for displays and lighting. Electronically, they allow faster electron transfer, boosting device performance. Additionally, their stability and photostability make them long-lasting. Understanding their size-dependent properties is crucial for harnessing their full potential in various applications. These properties are closely related to quantum confinement effects, which are fundamental to their behavior. Here’s what sets them apart:

- Size-dependent light emission

- Bright, pure colors

- High quantum efficiency

- Quick electron mobility

- Stable, long-lasting performance

Cutting-Edge Applications in Technology and Medicine

You can leverage quantum dots to revolutionize imaging techniques, providing sharper and more detailed visuals in medical diagnostics. These nanocrystals also boost solar energy conversion efficiency by capturing a broader spectrum of sunlight. As you explore these applications, you’ll see how quantum dots open new frontiers in technology and medicine. Electric buses and VW ID. Buzz exemplify sustainable innovations that are transforming transportation and energy use worldwide. Additionally, their unique quantum confinement effects enable precise tuning of optical properties, making them invaluable in advanced nanotechnology applications. Furthermore, researchers are exploring biomedical imaging techniques that benefit from the enhanced brightness and specificity of quantum dot-based probes. The ability to customize their optical characteristics through quantum confinement allows for tailored solutions in various high-tech fields.

Advanced Imaging Techniques

How are quantum dots revolutionizing imaging technology and medicine? They enable highly detailed, precise visualization that wasn’t possible before. Quantum dots’ tunable emission spectra allow for multi-color imaging with minimal overlap, improving clarity. They also provide brighter, more stable signals than traditional dyes, making long-term imaging feasible. Their high quantum yield ensures efficient light emission, reducing exposure times. Moreover, their small size allows for targeted delivery in biological systems, enhancing contrast and specificity. Additionally, decoding slang helps researchers better understand informal language used in patient interactions and social media, improving communication in healthcare settings.

Enhanced Solar Energy Conversion

Could quantum dots be the key to transforming solar energy technology? Absolutely. Their size-dependent optical properties allow them to absorb a broader spectrum of sunlight and convert it into electricity more efficiently than traditional materials. By tuning their bandgap through size control, you can optimize them to capture specific wavelengths, boosting overall energy output. Quantum dots also exhibit high photostability, making solar panels more durable and long-lasting. When integrated into photovoltaic cells, they enhance light absorption and charge separation, leading to increased power conversion efficiencies. Plus, their potential for reducing manufacturing costs and enabling flexible, lightweight solar panels makes them a promising solution for renewable energy. As research advances, quantum dot-enhanced solar technologies could markedly accelerate the shift toward sustainable, clean energy sources worldwide.

Advantages Over Traditional Materials

Quantum dots offer significant advantages over traditional materials because their unique size-dependent properties enable precise control over their optical and electronic behavior. This means you can tailor their emission colors, improve efficiency, and enhance stability. Unlike bulk materials, quantum dots have high quantum yields, making them brighter and more energy-efficient. Their narrow emission spectra ensure pure, vivid colors, perfect for displays and lighting. Additionally, they exhibit faster electron transfer, which benefits electronics and solar cells. You also gain versatility through various synthesis methods, allowing customization for specific applications. Their tunable properties allow for further optimization tailored to diverse technological needs. Moreover, ongoing research into reliable manufacturing techniques promises to expand their practical use and commercial viability. Advances in scalable production are making quantum dots more accessible for widespread commercial applications. These qualities make quantum dots ideal for cutting-edge devices, offering brighter, longer-lasting, and more precise performance compared to conventional materials. Additionally, their environmentally friendly nature makes them a more sustainable choice for future technological developments. For example, the development of cost-effective fabrication methods has been crucial in bringing quantum dot technology to mainstream markets.

Challenges and Future Directions in Quantum Dot Research

Despite the promising potential of quantum dots, researchers face several challenges that hinder their widespread application. Synthesizing uniform, high-quality quantum dots remains difficult, especially at scale, affecting consistency and performance. Toxicity concerns, particularly with materials like cadmium, pose environmental and health risks, limiting clinical and consumer use. Stability under prolonged exposure to light and heat also remains problematic, reducing device lifespan. Additionally, integrating quantum dots into existing technologies requires overcoming hurdles in charge transport and surface passivation. Future research must address these issues by developing eco-friendly materials, improving synthesis techniques, and enhancing stability. Collaborations across disciplines will be essential to translate laboratory breakthroughs into practical, scalable solutions, improving synthesis techniques, and ultimately unlock quantum dots’ full potential for next-generation devices and applications.

Innovations in Quantum Dot Design and Engineering

You can now explore how precise control over size and shape allows for tailored optical properties in quantum dots. Core-shell engineering enhances stability and quantum yield, enabling more efficient devices. Surface functionalization techniques further improve compatibility and functionality for specific applications.

Size and Shape Control

Controlling the size and shape of quantum dots is essential for tailoring their optical and electronic properties. Your ability to manipulate these parameters directly affects their emission wavelength, efficiency, and application suitability. By adjusting size, you can produce specific colors—from blue to red—since smaller dots emit higher-energy blue light, while larger ones glow red. Shape control, like creating rods or pyramids, influences how electrons move and interact within the dot. Techniques such as colloidal synthesis and advanced lithography enable precise size and shape tuning. To summarize:

- Smaller size results in higher-energy blue emission

- Larger size produces red light

- Shape impacts charge carrier dynamics

- Precise synthesis methods enable customization

- Uniformity enhances performance and consistency

Core-Shell Engineering

Core-shell engineering has revolutionized quantum dot design by enabling precise control over their optical and electronic properties. By layering a core material with a carefully chosen shell, you can enhance quantum yield, stability, and emission wavelength. This approach reduces surface defects that quench fluorescence and improves charge carrier confinement. For example, coating CdSe cores with ZnS shells boosts brightness and longevity. Different configurations include Type I and inverse Type I structures, tailored for specific applications like light-emitting devices or quantum computing.

| Core Material | Shell Material | Functionality |

|---|---|---|

| CdSe | ZnS | Brightness, stability |

| InP | ZnSe | Biocompatibility, emission |

| PbS | CdS | Infrared applications |

Surface Functionalization Techniques

Surface functionalization techniques have emerged as a vital advancement in quantum dot engineering, building on the foundations of core-shell design to further enhance their performance and versatility. These methods allow you to modify quantum dot surfaces with specific molecules or ligands, improving stability, solubility, and targeting capabilities. You can attach biomolecules for medical applications, passivate surface defects to boost brightness, or add functional groups for better integration into devices. Techniques such as ligand exchange, silanization, and polymer coating give you control over surface chemistry. This tailoring helps optimize quantum dots for diverse uses, from biomedical imaging to optoelectronics. By customizing surface properties, you open new potentials in quantum dot performance and expand their application horizons.

- Ligand exchange for targeted binding

- Silanization for chemical stability

- Polymer coating for biocompatibility

- Passivation to reduce surface traps

- Functional group attachment for device integration

The Impact of Quantum Dots on Everyday Life

Quantum dots have become increasingly common in your daily life, revolutionizing the way you experience digital displays, lighting, and imaging. They enhance the brightness, color accuracy, and energy efficiency of screens like TVs, smartphones, and monitors. In lighting, quantum dots produce vibrant, customizable colors for LEDs, making your home lighting more appealing. Medical imaging also benefits, with quantum dots providing clearer, more precise results in diagnostics. They enable brighter, longer-lasting displays and more efficient solar panels. Here’s a quick look at their influence:

| Application | Benefit |

|---|---|

| Digital Displays | Better colors and efficiency |

| Lighting | Bright, customizable illumination |

| Biomedical Imaging | Precise, high-resolution images |

| Solar Cells | Increased energy conversion |

Frequently Asked Questions

What Environmental Impacts Are Associated With Quantum Dot Manufacturing?

You should know that manufacturing quantum dots can pose environmental risks due to toxic materials like heavy metals such as cadmium and lead. During production, these substances might leak into soil and water systems, harming ecosystems and human health. Additionally, energy-intensive processes and waste management challenges contribute to pollution. To minimize impacts, it is crucial to develop greener synthesis methods and proper disposal practices.

Are Quantum Dots Safe for Long-Term Biomedical Applications?

Think of quantum dots as tiny superheroes in medicine—promising but still evaluating their long-term impact. While they show great potential for imaging and targeted therapy, concerns about toxicity and environmental buildup linger. You should stay informed, as ongoing research aims to improve their safety, making them more like trusted allies rather than risky strangers in your health journey. Caution and continued study are your best tools here.

How Cost-Effective Are Quantum Dot Production Methods at Scale?

Quantum dot production can be quite cost-effective at scale, especially with methods like colloidal synthesis, which is relatively inexpensive and easily scalable. You can produce large quantities with high precision, reducing costs per unit. However, some techniques like molecular beam epitaxy and X-ray lithography remain expensive due to their complexity and equipment needs. Overall, scaling up helps lower costs, making quantum dots more accessible for diverse applications.

Can Quantum Dots Be Integrated Into Existing Electronic Devices Easily?

Quantum dots can be integrated into existing electronic devices with remarkable ease, transforming technology like a superhero saving the day. You just need compatible fabrication techniques and proper interface engineering, which are already well-developed. By customizing size, shape, and surface chemistry, you can embed quantum dots into displays, sensors, or solar cells seamlessly. This adaptability makes incorporating quantum dots into current electronics straightforward, revealing vast potential for innovation without major overhauls.

What Are the Regulatory Challenges Facing Quantum Dot Commercialization?

You’ll face regulatory challenges like ensuring safety due to potential toxicity from materials like cadmium in quantum dots. You also need to navigate complex approval processes across different markets, which can delay commercialization. Additionally, you must address environmental concerns related to manufacturing and disposal. Staying updated on evolving regulations, conducting thorough safety testing, and collaborating with regulators will help you overcome these hurdles and bring quantum dot products to market smoothly.

Conclusion

Imagine holding a tiny, glowing city in your hand—quantum dots are just that small, yet they hold immense potential. As you explore their vibrant colors and innovative uses, remember they’re like miniature power plants, transforming technology and daily life. With breakthroughs happening every day, you’re on the brink of a future where these tiny dots brighten your world in ways you’ve never imagined. The future’s bright, and quantum dots are leading the way.