If you’re looking for the best 3D printers for jewelry casting in 2026, I recommend options like high-resolution resin printers such as the ANYCUBIC Photon Mono 4 10K and specialized castable resins like Siraya Tech Cast and SuperCast 8K. These tools deliver fine detail, clean burnouts, and reliable results. Want to find the perfect match for your needs? Keep going, and you’ll discover all the key features and top picks to help you succeed.

Key Takeaways

- The list features high-resolution LCD, DLP, and SLA printers compatible with advanced castable resins for detailed jewelry casting.

- It highlights top castable resins with excellent burnout, minimal ash, and fine detail capabilities for professional quality results.

- The selection emphasizes printers with fast curing speeds, large build volumes, and compatibility with ultra-high-resolution 8K and mono screens.

- It includes solutions suitable for small-scale hobbyist to high-volume professional jewelry production workflows.

- The guide considers resin versatility, ease of use, and reliable burnout performance essential for casting precision in 2026.

| Siraya Tech Cast UV-Curing Resin 500g |  | Best Castable Resin | Compatibility: Works with most LCD, DLP, SLA printers | Burnout Performance: Clean burnout, minimal ash | Resolution: High resolution, fine details | VIEW LATEST PRICE | See Our Full Breakdown |

| Siraya Tech Cast 3D Resin for Jewelry & Metal Parts |  | User-Friendly Choice | Compatibility: Most LCD and DLP printers, including 8K models | Burnout Performance: Easier to burn, minimal ash residue | Resolution: High precision, detailed models | VIEW LATEST PRICE | See Our Full Breakdown |

| SuperCast 8K 3D Printer Resin for Jewelry and Casting |  | Highest Resolution | Compatibility: Compatible with all LCD 3D printers | Burnout Performance: Burns out completely at low temps, no ash | Resolution: 8K, 22μm resolution | VIEW LATEST PRICE | See Our Full Breakdown |

| Siraya Tech Cast 3D Resin for Jewelry and Metals |  | Versatile Precision | Compatibility: Most LCD and DLP printers | Burnout Performance: Easy burn-out, minimal ash | Resolution: High resolution, smooth surface | VIEW LATEST PRICE | See Our Full Breakdown |

| Reprapper White-Wax Casting 3D Printer Resin (1kg) |  | Professional Jewelry Tool | Compatibility: Most 405nm LCD and DLP printers | Burnout Performance: Simple burn curve, no ash residue | Resolution: High resolution, detailed features | VIEW LATEST PRICE | See Our Full Breakdown |

| Castable 3D Printer Resin High-Temp Fast Curing 1kg |  | High-Temp Performance | Compatibility: Supports LCD, DLP, MSLA printers | Burnout Performance: Ultra-low ash, fast burn-out | Resolution: Ultra-high detail, 22μm | VIEW LATEST PRICE | See Our Full Breakdown |

| JAMG HE Jewelry Castable Resin for 3D Printing |  | Easy Casting Solution | Compatibility: DLP and LCD (including Mono) printers | Burnout Performance: No post-curing needed, complete burn-out | Resolution: High wax content, detailed prints | VIEW LATEST PRICE | See Our Full Breakdown |

| SuperCast 8K Resin for Jewelry & Metal Casting |  | Ultra-Fine Detail | Compatibility: All LCD 3D printers, including 8K models | Burnout Performance: Low ash, fast burn-out, no residue | Resolution: 8K, 22μm ultra-fine detail | VIEW LATEST PRICE | See Our Full Breakdown |

| Reprapper White-Wax Casting 3D Printer Resin (1kg) |  | Reliable Wax Model | Compatibility: Most LCD and DLP 405nm printers | Burnout Performance: Fast, clean burn-out, no ash residue | Resolution: High resolution, fine features | VIEW LATEST PRICE | See Our Full Breakdown |

| ANYCUBIC Photon Mono 4 10K Resin 3D Printer |  | Ultra-High Detail | Compatibility: Designed for LCD, DLP, mono printers | Burnout Performance: Fast, reliable burn-out, minimal ash | Resolution: 10K, 17μm pixel accuracy | VIEW LATEST PRICE | See Our Full Breakdown |

| Cast100P Green 3D Printer Resin for Jewelry (1kg) |  | Precision Casting | Compatibility**: Most 405nm DLP/LCD printers | Burnout Performance: Easy burn-out, minimal ash | Resolution: Ultra-high resolution, precise details | VIEW LATEST PRICE | See Our Full Breakdown |

| Formlabs True Cast Resin for 3D Printing |  | Premium Quality | Compatibility**: Suitable for LCD, DLP, and resin printers | Burnout Performance: Clean burn, low residue, stable during burn | Resolution: Very high detail, precise features | VIEW LATEST PRICE | See Our Full Breakdown |

More Details on Our Top Picks

Siraya Tech Cast UV-Curing Resin 500g

If you’re looking for a reliable resin for jewelry casting, Siraya Tech Cast UV-Curing Resin 500g stands out due to its excellent burnout performance. It contains wax components that burn out cleanly, producing minimal ash, which is perfect for thick designs like rings, medals, and metal prototypes. This resin is easy to print and compatible with most LCD, DLP, and SLA printers. Its bright blue color enhances surface finish and detail clarity. Whether you’re a beginner or an expert, Siraya Tech Cast True Blue simplifies casting with high-resolution detail, smooth surfaces, and reliable burnout, making it an ideal choice for jewelry and dental applications.

- Compatibility:Works with most LCD, DLP, SLA printers

- Burnout Performance:Clean burnout, minimal ash

- Resolution:High resolution, fine details

- Material Composition:Wax components, blue resin

- Build Volume:Not specified (small/medium scale)

- Ease of Use:User-friendly, no special environment needed

- Additional Feature:Bright true blue color

- Additional Feature:Soft, detailed capture

- Additional Feature:Suitable for thick designs

Siraya Tech Cast 3D Resin for Jewelry & Metal Parts

For jewelry makers and dental professionals seeking reliable casting results, Siraya Tech Cast 3D Resin stands out due to its high burnability and detailed resolution. It’s easy to use, compatible with most LCD and DLP 3D printers, including 8K models, and doesn’t require special additives or environments. Its wax components make it easier to burn out, ideal for small metal parts, jewelry, and intricate designs. The resin produces high-resolution models with smooth surfaces and precise details. Quick to print and simple to post-process, it offers an efficient solution for detailed, castable models in jewelry and dental applications.

- Compatibility:Most LCD and DLP printers, including 8K models

- Burnout Performance:Easier to burn, minimal ash residue

- Resolution:High precision, detailed models

- Material Composition:Wax components, purple resin

- Build Volume:Not specified (small/medium scale)

- Ease of Use:Easy to dye, post-process, no additives needed

- Additional Feature:Purple surface finish

- Additional Feature:Dyeable and post-process friendly

- Additional Feature:Supports most LCD/DLP printers

SuperCast 8K 3D Printer Resin for Jewelry and Casting

SuperCast 8K 3D Printer Resin stands out as the ideal choice for jewelers and casting professionals seeking ultrafine detail and clean burn-out in their work. Made in Korea by 3DMaterials, this wax-filled resin supports high-resolution 8K printing at 22μm, enabling intricate filigree and detailed jewelry designs. Its low viscosity allows for fast printing, and it requires no post-curing, preventing incomplete burning issues. The resin burns out fully at low temperatures with no ash residue, ensuring smooth casting processes. Plus, it’s compatible with all LCD 3D printers thanks to advanced photosensitization technology, making it versatile and reliable for professional jewelry casting.

- Compatibility:Compatible with all LCD 3D printers

- Burnout Performance:Burns out completely at low temps, no ash

- Resolution:8K, 22μm resolution

- Material Composition:Wax-filled, sturdy resin

- Build Volume:Not specified (small, detailed printing)

- Ease of Use:No post-curing, straightforward burn-out

- Additional Feature:Supports ultrafine filigree

- Additional Feature:No post-curing needed

- Additional Feature:Low viscosity for speed

Siraya Tech Cast 3D Resin for Jewelry and Metals

When selecting the right resin for jewelry casting, Siraya Tech Cast 3D Resin stands out thanks to its wax-like burnability and high-resolution capabilities. I’ve found it produces detailed, smooth models perfect for intricate jewelry pieces. Its purple color makes it easy to handle and post-process, and it adheres well to printing platforms, which simplifies printing for both beginners and pros. The resin’s quick print times save time without sacrificing quality. Plus, its burn characteristics make casting small metal parts, rings, and pendants more straightforward. Overall, Siraya Tech Cast resin offers a reliable, versatile solution for jewelers seeking precision and ease in their casting workflows.

- Compatibility:Most LCD and DLP printers

- Burnout Performance:Easy burn-out, minimal ash

- Resolution:High resolution, smooth surface

- Material Composition:Wax components, purple resin

- Build Volume:Not specified (small/medium)

- Ease of Use:Easy to print and handle, no special environment

- Additional Feature:Clear high-resolution details

- Additional Feature:Easy dyeing process

- Additional Feature:Versatile industry applications

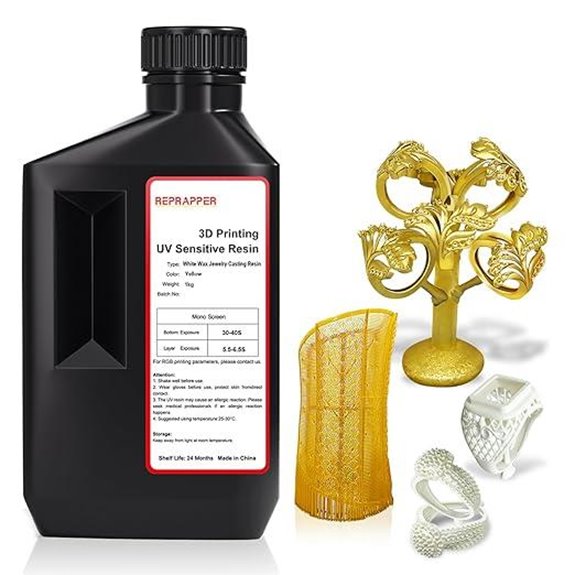

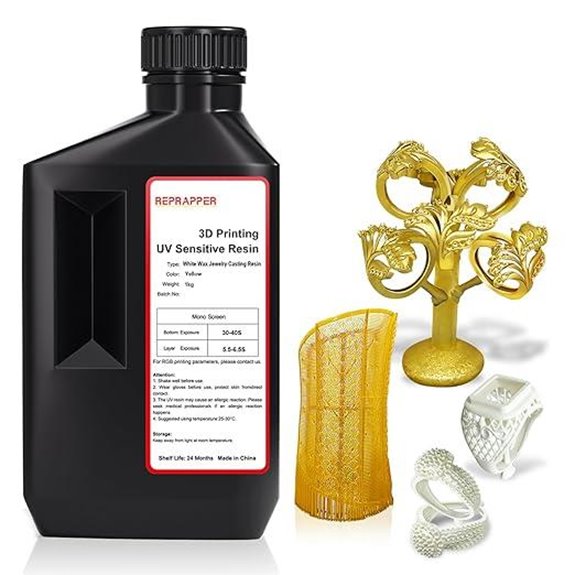

Reprapper White-Wax Casting 3D Printer Resin (1kg)

Reprapper White-Wax Casting 3D Printer Resin (1kg) stands out as an ideal choice for professionals seeking high-precision jewelry casting, thanks to its exceptional detail reproduction and smooth surface finish. This castable resin is compatible with most 405nm LCD and DLP printers, like B9C, Phrozen, Elegoo, and Anycubic. It produces high-quality wax models with high wax content, ensuring smooth resin flow and easier metal refilling during casting. The resin turns from yellow to pure white after curing, allowing for defect inspection. Its straightforward burn-out process minimizes ash and bubbles, speeding up production and ensuring accurate, reliable casting results.

- Compatibility:Most 405nm LCD and DLP printers

- Burnout Performance:Simple burn curve, no ash residue

- Resolution:High resolution, detailed features

- Material Composition:Wax-rich, castable resin

- Build Volume:Not specified (standard for jewelry)

- Ease of Use:Simple burn curve, easy to use

- Additional Feature:High wax content

- Additional Feature:White defect inspection

- Additional Feature:Faster burn-out times

Castable 3D Printer Resin High-Temp Fast Curing 1kg

If you’re looking for a reliable resin that delivers high-temperature resistance and fast curing times, this castable 3D printer resin is an excellent choice for jewelry makers. Designed specifically for metal casting, it’s compatible with LCD, DLP, and MSLA printers, ensuring versatility. With 1kg of vibrant purple resin, it offers high precision and captures intricate details like rings and pendants with clarity. Its excellent flow characteristics enable smooth printing and complete mold filling without additives. Plus, its ultra-low ash content results in minimal residue during burnout, leading to flawless castings and surface quality. This resin truly streamlines the jewelry casting process for professionals and enthusiasts alike.

- Compatibility:Supports LCD, DLP, MSLA printers

- Burnout Performance:Ultra-low ash, fast burn-out

- Resolution:Ultra-high detail, 22μm

- Material Composition:Small wax content, stable resin

- Build Volume:Not specified (small-scale)

- Ease of Use:Supports quick printing, easy to handle

- Additional Feature:Ultra-low ash content

- Additional Feature:Excellent mold filling

- Additional Feature:Precise detail reproduction

JAMG HE Jewelry Castable Resin for 3D Printing

JAMG HE Jewelry Castable Resin stands out for its high wax content and compatibility with DLP LCD Mono printers, making it an ideal choice for jewelers seeking precise, smooth finishes with minimal cracking. Its 1000g formulation is perfect for casting intricate jewelry pieces, even for those with little casting experience. The resin supports rapid printing—just 3-4 seconds per layer with DLP technology—enhancing efficiency. Developed by a team with 20 years of UV curing expertise, it offers a reliable, high success rate. The resin’s super easy casting process and smooth surface quality make it suitable for both beginners and professionals aiming for top-tier results.

- Compatibility:DLP and LCD (including Mono) printers

- Burnout Performance:No post-curing needed, complete burn-out

- Resolution:High wax content, detailed prints

- Material Composition:High wax content, stable, fast cure

- Build Volume:Not specified (suitable for jewelry)

- Ease of Use:Supports rapid, easy printing, stable recipe

- Additional Feature:High wax content

- Additional Feature:Rapid DLP/LCD printing

- Additional Feature:Stable recipe formulation

SuperCast 8K Resin for Jewelry & Metal Casting

SuperCast 8K Resin stands out as an ideal choice for jewelry makers seeking ultrafine detail and high-strength patterns. I’ve found it perfect for printing intricate filigree designs thanks to its wax-filled strength and stiffness. Its 8K resolution delivers stunning 22μm detail, and the low-viscosity formula allows for fast, high-resolution printing. Plus, it’s compatible with all LCD 3D printers, making it versatile. Best of all, no post-curing is needed, and it burns out cleanly at lower temperatures without ash residue, streamlining the casting process. Overall, SuperCast 8K Resin offers precision and efficiency for professional jewelry and metal casting applications.

- Compatibility:All LCD 3D printers, including 8K models

- Burnout Performance:Low ash, fast burn-out, no residue

- Resolution:8K, 22μm ultra-fine detail

- Material Composition:Wax-filled, strong, stiff resin

- Build Volume:6.04″ x 3.43″ x 6.49″

- Ease of Use:Fully assembled, quick setup, easy to operate

- Additional Feature:Made in Korea

- Additional Feature:Ultrafine filigree support

- Additional Feature:No post-curing required

Reprapper White-Wax Casting 3D Printer Resin (1kg)

Reprapper White-Wax Casting 3D Printer Resin (1kg) stands out as an ideal choice for professionals seeking high-resolution, castable resin compatible with most 405nm LCD and DLP printers. Its high wax content guarantees smooth surface finishes and accurate details, perfect for jewelry and intricate metal parts. The resin offers easy printing, post-processing, and a straightforward burn-out process with no ash residue, speeding up casting. Color transformation from yellow to white helps detect defects before casting. Its stability during curing and burn-out enhances dimensional accuracy and productivity, making it a reliable, high-quality option for professional jewelry casting.

- Compatibility:Most LCD and DLP 405nm printers

- Burnout Performance:Fast, clean burn-out, no ash residue

- Resolution:High resolution, fine features

- Material Composition:High wax content, castable resin

- Build Volume:Not specified (small/medium scale)

- Ease of Use:Easy to print, handle, and post-process

- Additional Feature:405nm UV compatibility

- Additional Feature:Smooth surface finish

- Additional Feature:Easy metal refilling

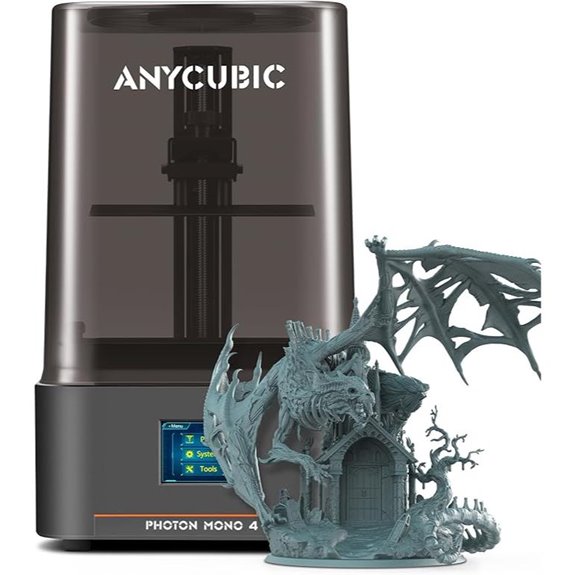

ANYCUBIC Photon Mono 4 10K Resin 3D Printer

If you’re seeking precision and speed in jewelry casting, the ANYCUBIC Photon Mono 4 10K Resin 3D Printer stands out with its ultra-high-resolution display and fast exposure times. Its 7-inch HD Mono LCD offers a 9024 x 5120 pixel resolution, capturing micro-details with 17×17μm accuracy. The printer’s 10K screen delivers exceptional clarity, making intricate designs easy to reproduce. With a 6.04″ x 3.43″ x 6.49″ build volume, it’s perfect for detailed resin prints. The LightTurbo light source guarantees stable, rapid layer curing at just 1.5 seconds per layer, boosting efficiency without sacrificing quality. Plus, it’s easy to set up and reliable.

- Compatibility:Designed for LCD, DLP, mono printers

- Burnout Performance:Fast, reliable burn-out, minimal ash

- Resolution:10K, 17μm pixel accuracy

- Material Composition:High wax, low ash, versatile

- Build Volume:6.04″ x 3.43″ x 6.49″

- Ease of Use:Quick start, simple calibration, reliable

- Additional Feature:10K HD resolution

- Additional Feature:Fast exposure times

- Additional Feature:Factory-calibrated for ease

Cast100P Green 3D Printer Resin for Jewelry (1kg)

For jewelry makers seeking high precision and detailed design verification, Cast100P Green 3D Printer Resin stands out as an ideal choice. Its jewel-green color enhances visibility during modeling, making it easier to verify intricate details. Compatible with most 405nm DLP and LCD printers, it guarantees high-resolution, accurate prints. The resin offers excellent dimensional stability with low thermal expansion, preventing deformation during casting. It produces minimal ash after burnout, simplifying removal and maintaining casting accuracy. Additionally, its low odor and easy cleanup improve the working environment. Overall, Cast100P delivers reliable, precise results perfect for detailed jewelry production and prototyping.

- Compatibility:Most 405nm DLP/LCD printers

- Burnout Performance:Easy burn-out, minimal ash

- Resolution:Ultra-high resolution, precise details

- Material Composition:Wax-rich, jewel-green resin

- Build Volume:1kg size, suitable for detailed jewelry

- Ease of Use:Easy to print, good flow, simple workflow

- Additional Feature:Jewel-green visual clarity

- Additional Feature:Low thermal expansion

- Additional Feature:Easy cleaning workflow

Formlabs True Cast Resin for 3D Printing

Formlabs True Cast Resin stands out as a top choice for jewelers and precision engineers seeking high-accuracy 3D printing materials. I’ve found it delivers consistent, detailed casts with crisp features and smooth surfaces, thanks to its low expansion and superior accuracy. It maintains surface integrity over time, preventing wax migration or residue buildup. The resin is reliable and forgiving, making casting easier with fewer defects. Its low ash content and shrinkage ensure clean burnout, fitting seamlessly into existing workflows. Perfect for intricate jewelry, heavy pieces, or complex engineering parts up to 5mm thick, it’s a versatile option for demanding applications.

- Compatibility:Suitable for LCD, DLP, and resin printers

- Burnout Performance:Clean burn, low residue, stable during burn

- Resolution:Very high detail, precise features

- Material Composition:Low ash, high stability resin

- Build Volume:Not specified (medium scale)

- Ease of Use:Reliable, consistent, user-friendly

- Additional Feature:Accurate, high-quality casting

- Additional Feature:Low shrinkage

- Additional Feature:Suitable for complex designs

Factors to Consider When Choosing 3D Printers for Jewelry Casting

When choosing a 3D printer for jewelry casting, I consider factors like resolution and detail level to guarantee precision in every piece. I also look at burnout compatibility and ease to avoid casting issues, along with material flexibility to match my project needs. Additionally, I evaluate printer compatibility features and post-processing requirements to streamline my workflow.

Resolution and Detail Level

High resolution is indispensable for capturing the intricate details that make jewelry pieces stand out. With 8K or 10K displays, 3D printers can achieve layer resolutions as low as 22μm, allowing for exceptional detail. This level of precision is critical for accurately reproducing delicate features like filigree, engravings, and tiny components. Resins designed for high-detail printing typically offer resolutions of 25μm or better, guaranteeing sharp, clean models. Ultra-fine resolution reduces surface roughness and visible layer lines, resulting in smoother finishes essential for casting. Combining high-resolution screens with specialized castable resins significantly enhances the fidelity of jewelry models. When choosing a printer, prioritize resolution to make certain your designs translate into precise, detailed, and high-quality casts.

Burnout Compatibility and Ease

Choosing a resin that’s compatible with your burnout process is vital for achieving clean, defect-free jewelry casts. I look for wax-filled or wax-compatible resins that burn out completely with minimal ash residue, reducing casting defects. Matching the resin’s burnout temperature to my casting process prevents incomplete combustion or mold damage. I prefer resins with a simple burn curve and a low ramp-up rate, like 2.33℃/min, which makes the burnout more efficient and thorough. It’s also important to verify that the resin has low ash content—ideally below 0.03%—to minimize debris that can cause imperfections. Consistency across different printers and setups is key, so I choose resins tested for reliable burn-out performance to ensure high-quality results every time.

Material Flexibility and Types

Having the flexibility to work with various castable resins is essential for achieving diverse jewelry designs and optimizing casting results. Different resins offer unique properties, such as wax-like burnouts that enable cleaner casting and easier removal, broadening material options. High-resolution printers can accurately reproduce intricate details across a range of materials, which is crucial for detailed jewelry pieces. Additionally, using different resin colors and formulations can improve visual inspection and streamline post-processing. Material properties like ash content, burnout temperature, and flexibility also influence the choice of printer, ensuring compatibility with specific casting techniques. Overall, a versatile printer that supports multiple resin types helps designers experiment and refine their creations, ultimately delivering higher quality and more innovative jewelry pieces.

Printer Compatibility Features

Selecting a 3D printer for jewelry casting requires careful attention to compatibility features that guarantee reliable and high-quality results. First, verify the printer works with castable resins containing wax components for easy burnout and minimal ash residue. High-resolution capabilities, like 8K or 10K screens, are essential for capturing fine jewelry details. Check that the printer’s exposure settings and wavelength match the specific curing requirements of your chosen resin. Compatibility with the resin’s recommended printing parameters and post-processing workflow is also critical. Additionally, look for features like fast layer curing and stable build plate adhesion to improve efficiency and casting precision. These compatibility factors are key to achieving consistent, detailed, and successful jewelry castings.

Post-Processing Requirements

Post-processing is a crucial step in ensuring the quality and accuracy of jewelry castings from 3D printed models. I’ve found that cleaning, curing, and sometimes dyeing are essential to achieve a smooth surface and fine detail. Resins with high wax content require careful burnout procedures to remove all ash, preventing casting defects. The ease of post-curing directly impacts dimensional stability and casting precision; some resins need specific curing times and light intensities. Proper cleaning methods, like alcohol baths or ultrasonic cleaning, are essential to eliminate uncured resin residues. This step can also influence workflow efficiency—resins with minimal post-processing needs are ideal for high-volume production. Considering these requirements helps me choose printers that streamline the entire jewelry casting process.

Cost and Budget Considerations

Choosing a 3D printer for jewelry casting involves balancing your budget with the desired level of detail and efficiency. High-resolution resin printers suitable for jewelry can cost from a few hundred to several thousand dollars, influencing your overall investment planning. If you’re on a tight budget, entry-level LCD or DLP printers offer a decent solution, though they may deliver lower resolution. Premium 8K printers, with advanced features and faster speeds, come at a higher price but provide superior detail and efficiency, which can save time and reduce errors. Don’t forget to account for ongoing costs like specialized castable resins, which vary in price. Investing in a reliable printer and quality resin can minimize failed prints, ultimately saving money over the long run.

Frequently Asked Questions

How Does Resin Color Impact Casting Detail and Finish Quality?

Resin color can affect casting detail and finish quality because darker resins tend to hide surface imperfections, resulting in a smoother final piece. Conversely, lighter or transparent resins reveal fine details more clearly, but flaws may be more visible. I recommend choosing a resin color based on your desired final look—darker shades for a polished finish, lighter for intricate detail—and always test for the best results.

What Is the Typical Resin Curing Time for Jewelry Applications?

Think of curing resin like baking a cake—you need the right time for everything to set perfectly. Typically, for jewelry applications, I find that curing takes about 30 to 60 minutes under a UV light or in sunlight. This guarantees the resin is fully hardened, giving you the sharp detail and smooth finish you want in your castings. Rushing it can lead to imperfections, so patience is key.

Are There Specific Safety Precautions for High-Temperature Resin Use?

Yes, there are specific safety precautions I follow when using high-temperature resin. I always wear gloves, goggles, and a respirator to protect my skin, eyes, and lungs from fumes and splashes. I also work in a well-ventilated area and avoid skin contact. Proper disposal of leftover resin and cured parts is essential. Following these steps keeps me safe while working with high-temperature resin.

How Do Compatibility and Resin Shelf Life Affect Long-Term Projects?

Did you know that resin shelf life typically ranges from one to two years? Compatibility and resin shelf life are vital for long-term projects because using incompatible resins can cause print failures, and expired resin may not cure properly. I always check the manufacturer’s recommendations and store resin in a cool, dark place. This way, I make certain my projects stay consistent and reliable over time.

What Post-Processing Steps Are Necessary for Optimal Casting Results?

After printing your model, I recommend washing it thoroughly in isopropyl alcohol to remove residual resin. Then, I cure it under UV light to guarantee full hardening, which improves casting accuracy. Sand or file any imperfections, and apply a mold release if needed. These steps help achieve smooth surfaces and precise details, resulting in high-quality jewelry castings that meet your expectations every time.

Conclusion

Choosing the right 3D printer for jewelry casting is like finding the perfect gem—you need precision, reliability, and quality. While high-tech resins promise intricate details, don’t forget the importance of ease of use and cost. It’s a balancing act, much like designing jewelry itself. So, whether you’re after stunning detail or budget-friendly solutions, remember: the right printer transforms your ideas into reality, turning visions into shining masterpieces.