I’ve researched the top wafer probing stations for 2025, focusing on precision, automation, and durability. These systems feature advanced calibration, adaptable probes, and automated handling to guarantee accurate testing of delicate wafers. They integrate seamlessly with existing lab setups and offer high repeatability. If you want insights into the best options for high-performance, reliable testing, keep exploring—I’ll guide you through the key features and benefits of each.

Key Takeaways

- Advanced measurement accuracy with low contact resistance, sub-micrometer adjustments, and high repeatability ensures precise wafer testing.

- Compatibility with diverse probe types, adjustable force, and support for multiple wafer sizes enable versatile testing configurations.

- Seamless integration with automation, remote control, and programmable multi-axis stages enhances testing efficiency.

- Durable, corrosion-resistant materials and modular design facilitate long-term reliability and easy maintenance.

- Automated sample handling features like loading/unloading, alignment, and secure clamping optimize throughput and reduce error.

TEMPO 811K Digital Tone Generator and Probe Kit

The TEMPO 811K Digital Tone Generator and Probe Kit stands out for its noise-immune tracing capabilities, making it an ideal choice for professionals working in high-electrical-noise environments. Its advanced digital signal processing technology guarantees precise wire identification, even amidst electrical interference. The kit’s compatibility with older tracing equipment allows seamless integration into existing setups. The simple, single-button probe control with real-time signal strength indication makes tracing quick and straightforward. Powered by AA batteries, it offers long-lasting operation and cost efficiency. Overall, this kit combines reliability, ease of use, and superior performance for accurate wire tracing in challenging conditions.

Best For: professionals and technicians working in high-electrical-noise environments who need reliable, accurate wire tracing.

Pros:

- Noise-immune tracing ensures accurate results even in electrically noisy settings

- Compatibility with older tracing equipment allows seamless integration into existing setups

- User-friendly single-button probe control with real-time signal strength indication simplifies operation

Cons:

- May require training for optimal use of digital signal processing features

- Battery dependency could necessitate frequent replacements or recharging if not using rechargeable AA batteries

- Higher initial cost compared to basic tone generators without digital features

Koolertron DDS Signal Generator Counter

If you need a versatile signal generator that combines high precision with remote control capabilities, the Koolertron DDS Signal Generator Counter is an excellent choice. It features a bright 2.8-inch display and supports dual-channel arbitrary waveform generation up to 60MHz. You can easily control it via a dedicated app on your phone, allowing data viewing, waveform import/export, and function setting, or operate it independently for flexibility. With high-stability FPGA hardware and an active crystal oscillator, it guarantees reliable output. Its ability to generate various signals—including sine, square, triangle, and user-defined waveforms—makes it ideal for precise testing in demanding environments.

Best For: electronic engineers, researchers, and technicians needing high-precision, remotely controllable signal generation for testing and experimentation.

Pros:

- Supports dual-channel arbitrary waveform generation up to 60MHz with stable low-distortion signals

- Equipped with a user-friendly 2.8-inch display and mobile app control for convenient operation and waveform management

- Offers comprehensive measurement functions and large storage for user-defined settings, enhancing versatility

Cons:

- Maximum sine wave output frequency is 80MHz, which may be limiting for some high-frequency applications

- Requires familiarity with PC software or mobile app for full functionality, potentially adding a learning curve

- Physical connection is not mandatory but may be preferred for some users preferring direct hardware control

110V Power Feed for Milling Machine, 650 in-lb Torque, Adjustable Speed

For those seeking reliable power and precise control in milling operations, the V Power Feed for Milling Machine stands out with its impressive 650 in-lb torque and adjustable speed feature. Designed for 110V operation, it offers smooth, stable transmission with high efficiency and low noise. Its rapid 0.2-second braking enhances workflow, while the manual stepless speed regulation allows for accurate adjustments from 2 to 200 RPM. Built with durable plastic gears and a protective clutch, it guarantees longevity and safety during heavy-duty tasks. Compatible with various milling machines, this power feed delivers consistent performance, making it an essential tool for precise and efficient machining.

Best For: hobbyists and professionals seeking reliable, precise power feeding for milling machines to improve accuracy and efficiency during heavy-duty machining tasks.

Pros:

- Provides high torque of 650 in-lb for powerful milling operations

- Adjustable speed range from 2 to 200 RPM for versatile control

- Durable plastic gears with safety clutch for extended lifespan and safety

Cons:

- Weighs 6kg (13.2 pounds), which may be heavy for some users to handle

- Requires 110V power supply, limiting use in areas with different voltage standards

- May have a learning curve for manual stepless speed regulation and installation

200a Meter Socket with Horn Bypass, 600V, 1 Phase, 3 Wire Ringless Type

A Meter Socket with Horn Bypass, 600V, 1 Phase, 3 Wire Ringless Type, stands out as an essential component for reliable residential electrical setups. Its 200A capacity and 5-jaw design ensure secure, stable connections for both overhead and underground feeds. Made from durable galvanized steel, it withstands wear and harsh conditions. The horn bypass feature allows for easy meter removal without disconnecting power, enhancing safety and convenience. Suitable for standard US meters, it supports up to 600 volts AC and wires up to 14-2 AWG. This socket ensures efficient, safe power distribution, making it a vital part of residential electrical infrastructure.

Best For: homeowners and electricians seeking a durable, reliable meter socket for residential electrical systems with easy meter removal and versatile installation options.

Pros:

- Constructed from sturdy galvanized steel for long-lasting durability and resistance to harsh conditions

- Features horn bypass for safe and convenient meter removal without power interruption

- Supports up to 600V and fits standard US meters, ensuring broad compatibility

Cons:

- May be larger or heavier than some other socket options, requiring sufficient space for installation

- Designed primarily for residential use, potentially limiting for commercial applications

- Installation requires some electrical expertise to ensure proper and safe setup

OWON SDS220S Digital Oscilloscope with Waveform Generator

The OWON SDS220S Digital Oscilloscope with Waveform Generator stands out as a versatile and cost-effective solution for electronics enthusiasts, engineers, and educators demanding reliable signal analysis and testing. It features a 200MHz bandwidth, dual channels, and a 1GSa/s sampling rate per channel, enabling precise measurements. The scope’s 7-inch LCD provides clear signal viewing, while its wide horizontal scale supports detailed analysis. Its integrated waveform generator offers 25MHz frequency and 125MSa/s sampling. Compact and lightweight, it’s ideal for bench, field, or lab use. With USB and remote control capabilities, it supports automation, making it a practical tool for diverse testing scenarios.

Best For: electronics enthusiasts, engineers, and educators seeking a reliable, portable oscilloscope with waveform generation capabilities for testing and learning.

Pros:

- Offers 200MHz bandwidth with dual channels and high sampling rates for precise signal analysis

- Compact, lightweight, and portable, suitable for bench, field, or educational use

- Supports remote control, USB communication, and SCPI for automation and secondary development

Cons:

- Physical interface controls could be larger or more intuitive for easier operation

- Screen may display pixelated waveforms and contain dead pixels, affecting visual clarity

- Being an entry-level device, it may lack advanced features found in higher-end oscilloscopes

Mini DDS Signal Generator with Waveform Output and Schumann Resonator

Offering precise frequency control across a wide range, the Mini DDS Signal Generator is ideal for hobbyists and professionals who need reliable, low-cost testing tools. It covers frequencies from 0.01Hz to 500kHz for sine waves and up to 100kHz for other waveforms, with 0.01Hz resolution. Its versatility includes sine, square, triangle, sawtooth, ECG, noise, and even a Schumann wave at 7.83Hz. Compact and portable, it’s perfect for oscilloscope calibration, circuit testing, and audio measurements. The device’s high stability and digital controls make it a practical choice for detailed electronic work, despite minor interface limitations.

Best For: hobbyists, electronics students, and professionals seeking an affordable, versatile signal generator for calibration, testing, and educational demonstrations.

Pros:

- Wide frequency range with high precision and stability

- Supports multiple waveforms including sine, square, triangle, sawtooth, ECG, and Schumann wave

- Compact, portable design ideal for desktop use and field testing

Cons:

- Tedious interface for adjusting and cycling frequencies, especially during dynamic testing

- Limited ease of changing frequencies quickly or performing sweep functions

- Display readability issues at certain angles and some reports of hardware defects

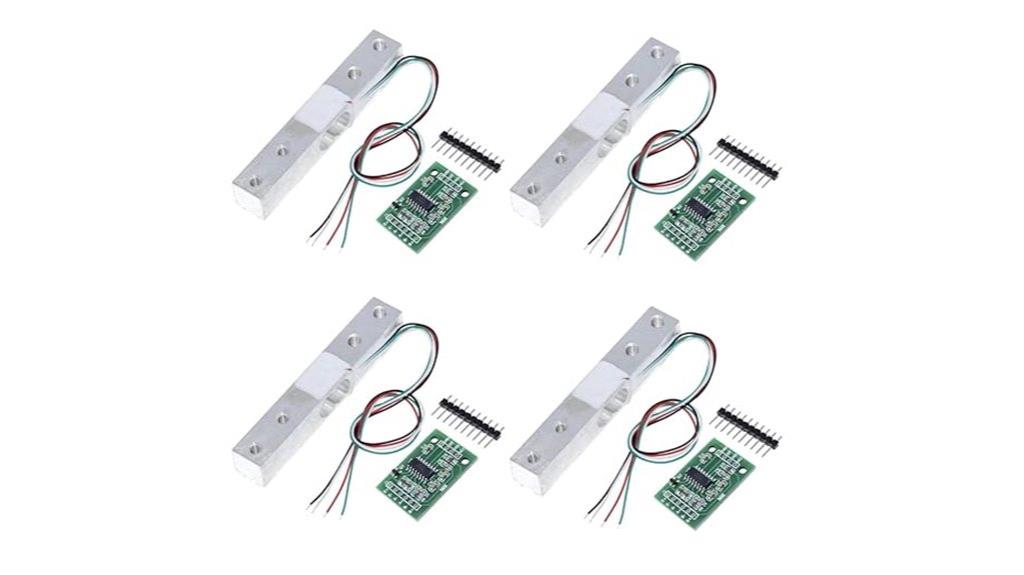

ShangHJ Digital Load Cell Weight Sensor & HX711 Module Kit

For DIY electronics enthusiasts and precision weight measurement projects, the ShangHJ Digital Load Cell Weight Sensor & HX711 Module Kit stands out due to its straightforward setup and high accuracy. The load cell supports a 10kg capacity with four leads—red, black, green, and white—providing voltage signals proportional to applied force. The HX711 module features a 24-bit ADC with dual channels and adjustable gain, ensuring precise readings. It connects easily to microcontrollers like Arduino or Raspberry Pi, with clear color-coded wiring. While installation requires careful wiring and awareness of the load cell’s orientation, this kit delivers consistent results ideal for digital scales, automation, and IoT applications.

Best For: DIY electronics enthusiasts and hobbyists seeking a high-precision, easy-to-assemble weight measurement solution for projects like digital scales, automation, and IoT systems.

Pros:

- Simple wiring with color-coded cables makes setup straightforward.

- High-precision 24-bit ADC ensures accurate and repeatable measurements.

- Compatible with popular microcontrollers like Arduino and Raspberry Pi for versatile use.

Cons:

- No explicit orientation markings require careful installation and prior knowledge.

- Proper wiring and handling are essential to prevent damage and ensure accurate results.

- Limited to low-cost, small-capacity applications (10kg max), not suitable for heavy-duty weighing.

DDS Function Signal Generator with BNC Cable

A DDS Function Signal Generator with BNC Cable stands out for its precise frequency control and versatile waveform outputs, making it ideal for engineers and technicians focused on detailed electronic testing. It covers a frequency range from 0.01Hz to 500kHz for sine waves and up to 100kHz for other waveforms, supporting applications like circuit debugging, frequency response analysis, and audio testing. Its filter options deliver cleaner signals at higher frequencies, while the waveform mode and amplitude controls offer flexibility. With adjustable DC bias, saveable settings, and compatibility with oscilloscopes, this generator simplifies calibration and measurement tasks, ensuring accurate results for complex testing scenarios.

Best For: electronic engineers, technicians, and hobbyists needing precise waveform generation and calibration for circuit testing and analysis.

Pros:

- Wide frequency range covering 0.01Hz to 500kHz for sine waves and up to 100kHz for other waveforms, suitable for various testing needs.

- Features like filters, waveform mode selection, amplitude adjustment, and adjustable DC bias enhance signal quality and flexibility.

- Saveable settings and compatibility with oscilloscopes streamline calibration, measurement, and repetitive testing tasks.

Cons:

- Output amplitude decreases at higher frequencies, which may require additional amplification for certain applications.

- Power options are limited to 4-9V DC adapters or 3.7V batteries, possibly restricting portability.

- Requires manual adjustment of filters and settings, which may be complex for novice users.

Factors to Consider When Choosing High‑Performance Wafer Probing Stations

When selecting a high-performance wafer probing station, I focus on measurement accuracy and probe compatibility to guarantee reliable testing. I also consider automation features and sample handling to boost efficiency and integration with existing systems. Addressing these factors helps me choose equipment that meets both precision and operational needs.

Measurement Accuracy and Precision

Measurement accuracy and precision are essential factors to contemplate when selecting a high-performance wafer probing station. Accurate measurements rely on low probe contact resistance, with top stations achieving resistances below 10 milliohms, ensuring reliable data. Precision depends on the stability of the probe positioning system, which must allow sub-micrometer adjustments for detailed measurements. High-accuracy stations incorporate advanced calibration methods, like standard reference wafers, to maintain traceability and reduce systematic errors. Signal integrity also plays a fundamental role; noise reduction and shielding improve the resolution and dependability of wafer parameter readings. Additionally, repeatability is indispensable—top-tier stations deliver consistent results with less than 1% variation across multiple tests. Together, these factors guarantee precise, trustworthy measurements critical for high-performance testing.

Probe Compatibility and Range

Have you ever considered whether your wafer probing station supports the specific probe sizes and types needed for your devices? Ensuring compatibility with needle, blade, or microprobes is essential for accurate testing. You also need to verify that the probe range covers the pitch and contact pad dimensions of your wafers to avoid misalignment or damage. Compatibility with various probe card configurations, such as multi-site and high-density arrays, can greatly boost testing efficiency. Adjustable probe force and height settings are vital for accommodating different wafer thicknesses and probe specifications, preventing damage and ensuring consistent contact. Finally, supporting both standard and custom probes provides the flexibility needed to handle diverse testing applications, making your station versatile and future-proof.

Automation and Control Features

Automation and control features play a pivotal role in maximizing the efficiency and accuracy of high-performance wafer probing stations. Programmable multi-axis control systems improve precision and reduce manual adjustments, streamlining the testing process. Integration with sophisticated software interfaces enables remote operation, real-time monitoring, and automated test sequences, saving time and minimizing human error. Adaptive control algorithms dynamically optimize probe placement and contact force, guaranteeing consistent contact quality across wafers. Additionally, feedback mechanisms like load sensors and position encoders provide real-time data, further enhancing contact reliability. These automation capabilities markedly boost throughput without compromising accuracy or repeatability, making them essential for high-volume, precision wafer testing environments. Choosing a station with advanced control features ensures reliable, efficient, and scalable testing operations.

Sample Handling Capabilities

Choosing a high-performance wafer probing station requires careful attention to its sample handling capabilities, as this directly impacts testing accuracy and efficiency. I look for stations that support the maximum sample size and weight, ensuring compatibility with my wafer dimensions and handling needs. It’s vital that the system can accommodate various wafer types and sizes, including fragile, thin, or multi-die wafers, to prevent damage during loading. Precise alignment features, like automated or manual stage adjustments, help maintain accuracy and protect delicate samples. Secure, contamination-free loading mechanisms such as vacuum chucks or electrostatic clamps are essential for reliable handling. Additionally, compatibility with automated handling systems or robotic arms can considerably boost throughput and reduce manual intervention, streamlining the entire testing process.

Integration With Testing Systems

Ensuring seamless integration of wafer probing stations with existing testing systems is crucial for maximizing throughput and data accuracy. Compatibility with automated test equipment (ATE) is essential, so I look for stations that support standard communication protocols like GPIB, USB, or Ethernet. These enable smooth remote control and efficient data exchange. Modular design is also important, as it allows for easy upgrades and customization to match specific test needs, ensuring compatibility with diverse measurement instruments. Precise alignment and positioning features guarantee reliable contact with wafer pads, which is essential for accurate data collection within integrated setups. Additionally, compatibility with software automation platforms and test management systems streamlines workflow, reduces setup time, and enhances overall testing efficiency.

Reliability and Maintenance

Reliable operation of wafer probing stations depends heavily on regular maintenance and high-quality construction. Regular calibration and cleaning of probing contacts are crucial to maintain measurement accuracy and prevent signal degradation. Choosing a station made from durable, corrosion-resistant materials reduces maintenance needs and extends equipment lifespan. Accessibility to replacement parts and a modular design simplify routine upkeep and minimize downtime. Implementing a scheduled maintenance routine helps identify wear and potential failures early, ensuring consistent reliability. High-quality probing stations with robust construction and stable connections lower the risk of contact failure and promote long-term stability. Overall, investing in reliable equipment with easy maintenance features ensures consistent performance, reduces operational disruptions, and maximizes testing efficiency over time.

Frequently Asked Questions

What Are the Latest Technological Advancements in Wafer Probing Stations for 2025?

The latest advancements in wafer probing stations for 2025 include AI-driven automation, ultra-high precision multi-site testing, and enhanced thermal management systems. I’ve noticed that these innovations boost testing speed and accuracy while reducing errors and downtime. New materials and miniaturized components also improve durability and probe life. These technological leaps enable more efficient, reliable, and scalable semiconductor testing, ultimately supporting faster development cycles and higher-quality chips.

How Do Environmental Factors Affect the Accuracy of High-Performance Wafer Testers?

Environmental factors like temperature fluctuations, humidity, and vibrations can considerably impact the accuracy of high-performance wafer testers. I’ve seen how even small changes can cause measurement errors or equipment drift. That’s why I always make certain testing environments are tightly controlled, with stable temperatures, low humidity, and vibration isolation. Maintaining these conditions helps me achieve consistent, precise results and reliable data during wafer testing processes.

What Safety Features Are Essential for Modern Wafer Probing Equipment?

I believe safety features are vital in modern wafer probing equipment. Essential ones include emergency stop buttons for quick shutdowns, protective shields to prevent accidental contact, and proper grounding to avoid electric shocks. Additionally, I prioritize automatic fault detection systems that alert operators to issues, ensuring safe operation. These features not only protect personnel but also maintain the integrity of sensitive equipment during high-precision testing.

How Does Automation Improve Testing Efficiency in Wafer Probing Stations?

Automation boosts testing efficiency in wafer probing stations by reducing manual intervention and speeding up processes. I’ve seen how automated systems can quickly align wafers, execute multiple tests simultaneously, and log data accurately, saving time and minimizing errors. This allows for higher throughput and more consistent results, which is essential for maintaining quality in production. Overall, automation makes testing faster, more reliable, and easier to manage.

What Are the Cost Considerations When Upgrading to High-Performance Wafer Testing Systems?

When upgrading to high-performance wafer testing systems, cost considerations are vital. I find that initial investment can be steep, but it pays off in long-term savings through increased efficiency and reduced downtime. Don’t forget to budget for training, maintenance, and potential upgrades. It’s a balancing act—sometimes you need to spend a little to get a lot, but careful planning guarantees you don’t bite off more than you can chew.

Conclusion

Choosing the right high-performance wafer probing station is vital for precision testing. Did you know that the global semiconductor testing equipment market is expected to reach $12 billion by 2025? With the right tools, like the ones I’ve highlighted, you can guarantee accuracy and efficiency in your testing processes. Investing wisely now means staying ahead in this rapidly evolving industry. Let’s make certain your equipment meets the high standards needed for tomorrow’s innovations.