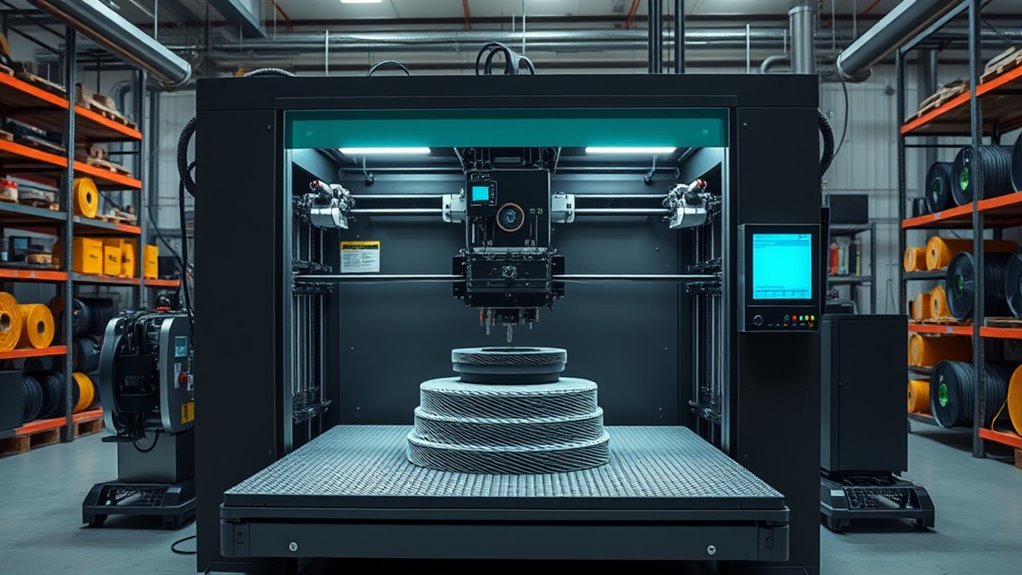

If you’re looking for the top industrial FDM 3D printers for heavy-duty manufacturing in 2025, I’ve got some excellent options to share. These include models like the QIDI MAX3, ELEGOO Neptune 4 Plus, and Longer LK5 Pro variants, all offering large build volumes, high speeds, and tough material support. These machines are built for precision, durability, and efficiency, making them perfect for demanding industrial use. Stay tuned to discover insights into each model and how to choose the best fit for your needs.

Key Takeaways

- Focus on printers with large build volumes and high-speed capabilities for efficient manufacturing of heavy-duty parts.

- Prioritize models with robust, all-metal frames and mechanical stability to ensure durability during demanding operations.

- Select printers supporting high-performance materials like CF-reinforced filaments for enhanced strength and wear resistance.

- Consider user-friendly features such as automatic calibration and minimal setup for streamlined industrial workflows.

- Evaluate firmware and software flexibility, including open-source options, for customization and long-term maintenance.

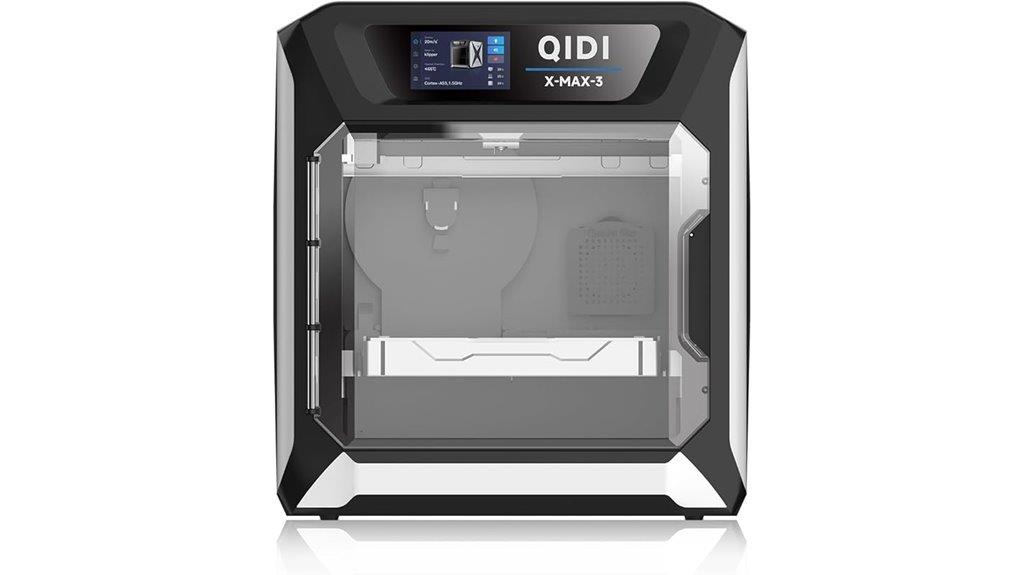

QIDI MAX3 3D Printer

If you’re looking for an industrial-grade 3D printer that combines speed, large build volume, and versatility, the QIDI MAX3 is an excellent choice for heavy-duty manufacturing. It reaches speeds up to 600mm/s with strong acceleration, allowing rapid production of large parts. Its sizable build area—325×325×315mm—lets you print big objects in one piece, saving time and assembly. The all-metal frame, heated chamber, dual cooling fans, and reinforced components ensure stability and durability. Supporting high-performance materials like PA12-CF and PET-CF, alongside standard filaments, it’s ideal for prototypes, functional parts, and artistic projects. Its user-friendly features make it suitable for both pros and beginners.

Best For: professionals and hobbyists seeking a high-speed, large-format industrial-grade 3D printer capable of producing complex, sizable parts with high precision and durability.

Pros:

- Exceptional build volume of 325×325×315mm allows large and complex prints in a single piece

- High-speed printing up to 600mm/s with strong acceleration for rapid production

- Supports a wide range of materials, including high-performance composites like PA12-CF and PET-CF

Cons:

- Some design flaws such as tight covers and sharp-edged handles may require modification or sanding

- Assembly can be simplified but still requires familiarity with maintenance procedures and software updates

- Potential complications when updating firmware via certain interfaces, requiring careful software management

ELEGOO Neptune 4 Plus 3D Printer

The ELEGOO Neptune 4 Plus stands out for its impressive speed and large build volume, making it an excellent choice for users who need high throughput and the ability to produce sizable or multiple parts in a single print. With speeds up to 500mm/s supported by Klipper firmware and accelerations of 12,000mm/s², it delivers rapid, high-quality results. Its 320x320x385mm build area accommodates large models or multiple objects simultaneously. Equipped with a dual-gear direct drive extruder, hotend capable of 300°C, and automatic calibration features, it guarantees precise, reliable printing across various filament types, ideal for demanding manufacturing environments.

Best For: hobbyists, educators, and small-scale manufacturers seeking a high-speed, large-volume 3D printer with reliable performance and easy operation.

Pros:

- Supports lightning-fast printing speeds up to 500mm/s with high acceleration for rapid production

- Large build volume of 320x320x385mm ideal for big models or multiple objects in one print

- Equipped with automatic calibration features, dual-gear direct drive extruder, and versatile filament compatibility

Cons:

- Setup instructions are not fully detailed, requiring users to research calibration and operation procedures

- WiFi connectivity and print resume functions can sometimes be unreliable or require troubleshooting

- Proper calibration and filament selection are crucial for optimal quality, which may pose a learning curve for beginners

Longer LK5 Pro 3D Printer (95% Pre-Assembled)

The Longer LK5 Pro 3D Printer stands out for its exceptional stability and ease of setup, making it an ideal choice for professionals who need reliable, heavy-duty manufacturing capabilities. Its sturdy triangular frame and reinforced inclined rods minimize resonance errors, ensuring precise prints. The silicon carbide lattice glass platform guarantees uniform temperature and strong bed adhesion, while the Teflon tube and dual cooling fans optimize filament flow and extrusion. With a large build volume of 11.8 x 11.8 x 15.7 inches and compatibility with various materials, it supports extensive projects. Being 95% pre-assembled makes setup straightforward, helping me get started quickly with minimal fuss.

Best For: professionals and hobbyists seeking a reliable, high-precision 3D printer with a large build volume and easy setup for complex projects.

Pros:

- Sturdy triangular frame and reinforced rods ensure high stability and precise prints

- Large build volume of 11.8 x 11.8 x 15.7 inches supports extensive creative projects

- 95% pre-assembled design simplifies setup and reduces installation time

Cons:

- Slightly higher price point compared to entry-level 3D printers

- May require technical knowledge for firmware customization and advanced troubleshooting

- Large size may require ample workspace and proper storage conditions

Longer LK5 Pro 3D Printer (11.8×11.8×15.7in, Fully Open Source)

Designed for heavy-duty manufacturing, the Longer LK5 Pro stands out with its expansive 11.8 x 11.8 x 15.7-inch build volume and robust delta-style frame, making it ideal for large, complex projects. Its reinforced inclined rods form a stable triangular structure, reducing vibration and wobble during high-speed printing. The delta design ensures consistent stability for detailed, long-duration prints. Equipped with automatic X and Y-axis calibration and a silicon carbide lattice glass platform, it achieves high accuracy and strong adhesion. Capable of printing at 180mm/s, it balances speed with precision. Fully open source, it invites customization and community engagement, making it a versatile choice for advanced manufacturing needs.

Best For: hobbyists, educators, and small-scale professionals seeking a large, stable, and highly accurate 3D printer with customizable features.

Pros:

- Large build volume (11.8 x 11.8 x 15.7 inches) ideal for big projects and complex models

- Stable delta-style frame with reinforced inclined rods reduces vibration and wobble during high-speed printing

- Fully open-source firmware and motherboard support customization, community engagement, and advanced modifications

Cons:

- May require some technical expertise for setup and customization due to open-source nature

- Larger size and weight could be less suitable for limited workspace or portability needs

- Initial assembly, while simplified, might still be time-consuming for beginners unfamiliar with 3D printers

QIDI MAX3 3D Printer

If you need a high-performance 3D printer capable of handling large, complex projects quickly and reliably, the QIDI MAX3 stands out as an excellent choice. It features a large build volume of 325×325×315mm, with a top speed of 600mm/s and advanced acceleration. Its all-metal frame, heated chamber, dual hotends, and support for high-performance materials like PA12-CF and PET-CF ensure durability and versatility. With auto-leveling, Klipper firmware, and user-friendly software, it delivers precise, detailed prints suitable for prototypes, functional parts, or artistic models. Support from QIDI is responsive, and the design emphasizes stability, making it ideal for heavy-duty manufacturing needs.

Best For: professionals and hobbyists seeking a large-scale, high-speed 3D printer capable of producing detailed, durable parts with versatile material support.

Pros:

- Large build volume of 325×325×315mm allows for printing sizable and complex models in one piece.

- High-speed capability of 600mm/s with advanced acceleration for efficient production.

- Robust all-metal frame, heated chamber, and dual hotends ensure stability, durability, and versatile material handling.

Cons:

- Slightly tight top cover and sharp-edged handle may require minor modifications or care during assembly.

- Firmware and software updates, especially via SSH, are necessary for optimal operation, which may be complex for beginners.

- Some initial design discrepancies, like the carbon filter cover, may need adjustments or replacements from the manufacturer.

ELEGOO Neptune 3 Pro 3D Printer

For those seeking a compact yet reliable 3D printer capable of handling small to medium-sized projects with precision, the ELEGOO Neptune 3 Pro stands out. It offers a 225x225x280mm build volume, perfect for versatile applications. The dual synchronized lead screws and dual-motor Z-axis drive ensure stable, accurate movement, while the POM V-guide rails reduce noise and wear. Its dual-gear direct extruder, made of SUS303 stainless steel, provides strong filament feeding compatible with various materials like PLA, TPU, PETG, and ABS. The auto bed leveling sensor, combined with filament run-out detection and resume function, guarantees consistent, high-quality prints with minimal hassle.

Best For: hobbyists, educators, and small-scale creators seeking a reliable, easy-to-setup 3D printer for small to medium projects with high precision.

Pros:

- Stable and precise dual-motor Z-axis for accurate movement and high-quality prints

- Auto bed leveling sensor ensures consistent adhesion and reduces manual calibration efforts

- Quiet operation with silent stepper motors minimizes noise during printing

Cons:

- Limited build volume may restrict larger project sizes

- Slightly complex setup for absolute beginners unfamiliar with 3D printing calibration

- Material compatibility, while broad, may require adjustments for certain filaments like ABS or TPU

Creality K2 Plus 3D Printer

The Creality K2 Plus 3D Printer stands out as an ideal choice for heavy-duty manufacturing environments that demand high speed and large build volumes. It supports multi-color and multi-material printing via Creality CFS connection, allowing for complex, vibrant designs. With a blazing speed of 600mm/s and 30,000mm/s² acceleration, it minimizes wait times while maintaining quality. Its sizable 350x350x350mm workspace suits large objects and batch production. Advanced automation features, including 18 sensors and dual AI cameras, ensure flawless first layers and reduce errors. Ready to use right out of the box, it combines power, precision, and user-friendliness for demanding industrial applications.

Best For: professionals and manufacturing environments requiring high-speed, large-volume, multi-material 3D printing with automation and precision.

Pros:

- Supports multi-color/multi-material printing for complex designs.

- Extremely fast printing speed of 600mm/s with high acceleration.

- Large build volume of 350x350x350mm suitable for big projects and batch production.

Cons:

- Requires Creality CFS connection, which is not included and may add complexity.

- Advanced features and automation may have a learning curve for new users.

- Potentially higher cost due to industrial-grade capabilities and sensors.

TINA2S 3D Printer with WiFi Printing

The TINA2S 3D Printer with WiFi Printing stands out as an excellent choice for educators, hobbyists, and small-scale users seeking an affordable, user-friendly, and versatile 3D printing solution. Its compact design measures just 8.2 x 8.2 x 11.4 inches and weighs only 6.16 pounds, making it perfect for home, classroom, or office environments. It features auto bed leveling, silent operation, and open-source firmware for customization. With WiFi cloud printing via the Poloprint Cloud App, users can control prints remotely from various devices. Its straightforward setup, high-quality results, and responsive support make it an ideal entry-level 3D printer.

Best For: beginners, educators, and hobbyists looking for an affordable, easy-to-use 3D printer suitable for small projects at home or in the classroom.

Pros:

- User-friendly setup with automatic bed leveling and clear on-screen guidance

- Compact, lightweight design ideal for limited space environments

- Supports WiFi cloud printing, enabling remote control from multiple devices

Cons:

- Limited to 12V operation without a heated bed, restricting high-temperature filament use

- Some users experience occasional issues with filament feeding and SD card reader functionality

- Cooling may require adjustments due to the lack of internal fans, affecting print finish on detailed models

Anycubic Kobra 3 V2 Combo 3D Printer

If you’re seeking a versatile 3D printer capable of high-speed, multi-color production, the Anycubic Kobra 3 V2 Combo stands out as an excellent choice. It offers advanced multi-color printing with options for 4 or 8 colors, plus a nozzle technology that reduces leakage for smoother finishes. With speeds up to 600mm/s and a maximum acceleration of 20,000mm/s², it’s incredibly fast—producing a boat in just 11.5 minutes. The auto-bed leveling ensures precise first layers, while the active filament drying system maintains filament quality. Though its software can be clunky and filament waste during color changes is a concern, it’s a reliable, high-speed option for demanding multi-material projects.

Best For: hobbyists and professionals seeking high-speed, multi-color 3D printing with advanced features and reliable performance.

Pros:

- Supports up to 8-color multi-material printing with advanced nozzle technology for smoother finishes.

- Extremely fast printing speeds of up to 600mm/s, significantly reducing production time.

- Features auto-bed leveling and active filament drying for high-quality, consistent prints.

Cons:

- Software interface is somewhat clunky and may require switching to alternative slicers like Orca.

- Filament waste during color changes and purging can be substantial, necessitating waste management solutions.

- Firmware updates can be complicated and may risk bricking the motherboard if not done carefully.

FLASHFORGE AD5M Pro 3D Printer with High-Speed & Precision

Designed for demanding manufacturing environments, the FlashForge AD5M Pro stands out with its high-speed printing capabilities and precise performance, making it ideal for heavy-duty production tasks. Its fully enclosed, compact design guarantees safety and reduces noise, with operation levels at 50dB and a silent mode for focused work. Setup is straightforward, featuring an intuitive touch screen, automatic bed leveling, and a removable build plate for easy print removal. Capable of reaching speeds up to 600mm/s, it supports multi-material filaments like TPU, ASA, and PETG, with a high-temp extruder and quick-detachable nozzles. This combination of speed, precision, and versatility makes it a strong choice for industrial-scale manufacturing.

Best For: professionals and manufacturers seeking high-speed, precise 3D printing capabilities for demanding production environments.

Pros:

- Exceptional high-speed printing up to 600mm/s with consistent quality

- Fully enclosed design with effective noise reduction and safety features

- Supports multi-material filaments with a high-temp extruder and quick-detachable nozzles

Cons:

- Initial setup and cable connections can be challenging, especially with non-standard sockets

- Software compatibility issues on newer macOS platforms might require troubleshooting

- Some noise from fans and airflow turbulence during operation

TINA2 Mini 3D Printer for Beginners

For beginners seeking an easy-to-use 3D printer that delivers reliable results, the TINA2 Mini 3D Printer by HEPHI3D stands out as an excellent choice. Its compact design measures just 8.27 x 8.27 x 11.42 inches and weighs only 5.68 pounds, making it perfect for small spaces and educational settings. Comes fully assembled, with a sample filament and preloaded models for instant printing. Features like a 2.4 LCD display, automatic bed leveling, and a removable magnetic build plate simplify operation and improve print quality. Supporting PLA, PLA Pro, and TPU, it’s ideal for beginners exploring 3D printing at home or in classrooms.

Best For: beginners, students, and educators seeking an easy-to-use, reliable 3D printer for small-scale projects and educational purposes.

Pros:

- Fully assembled and ready to use out of the box, ideal for beginners.

- Compact and lightweight design suitable for small spaces and portability.

- Features automatic bed leveling and a magnetic build plate for easy operation and model removal.

Cons:

- Limited build volume may restrict the size of larger projects.

- Compatibility primarily with PLA, PLA Pro, and TPU filaments, limiting material options.

- Slightly lower maximum resolution compared to more advanced 3D printers.

Longer LK5 Pro 3D Printer with Large Printing Size

The Longer LK5 Pro 3D Printer stands out for its impressive large build volume of 11.8 x 11.8 x 15.7 inches, making it an ideal choice for professionals and educators tackling sizable projects. Its reinforced inclined rods form a stable triangular structure, reducing vibration and wobble during high-speed printing. The delta-style frame ensures consistent stability, allowing for detailed, long-duration prints without layer shifts. Equipped with automatic X and Y-axis calibration and a silicon carbide lattice glass platform, it guarantees precise adhesion and accuracy up to 0.1mm. Its high-speed capability of 180mm/s, combined with features like auto-resume and open-source firmware, makes it versatile and user-friendly.

Best For: Professionals, educators, and hobbyists seeking a large-volume 3D printer capable of high-speed, precise, and stable printing for sizable projects.

Pros:

- Large build volume of 11.8 x 11.8 x 15.7 inches, ideal for big models and complex designs

- Reinforced triangular frame and delta-style structure ensure excellent stability and minimal wobble during high-speed printing

- Equipped with automatic calibration, auto-resume, and high-speed printing up to 180mm/s for efficient, high-quality results

Cons:

- Slightly complex setup due to various features, requiring familiarity with 3D printing operations

- Larger footprint may require more space and stable surface for optimal use

- Open-source firmware and advanced features might be overwhelming for absolute beginners without additional guidance

Tina2S 3D Printer with WiFi & Auto Leveling

If you’re seeking a user-friendly 3D printer that combines intelligent connectivity with reliable performance, the Tina2S with WiFi and auto leveling is an excellent choice. Its compact, fully assembled design makes it perfect for beginners, students, and small offices. The built-in LED light helps me monitor prints in real-time, while the quick-change nozzle simplifies maintenance. With Poloprint Cloud app support, I can easily manage files and control the printer remotely. The auto leveling system ensures precise prints, and the flexible build plate prevents warping. Delivering high-resolution results at up to 200mm/s, the Tina2S offers a quiet, efficient, and easy-to-use experience for various applications.

Best For: beginners, students, and small offices seeking an easy-to-use, reliable, and connected 3D printing solution.

Pros:

- Fully assembled, ready-to-use design ideal for newcomers

- Supports multiple connectivity options including WiFi and app control

- Auto leveling and flexible build plate for precise, warping-free prints

Cons:

- Limited build volume due to compact size

- May require initial setup and calibration for optimal performance

- Slightly higher cost compared to basic manual 3D printers

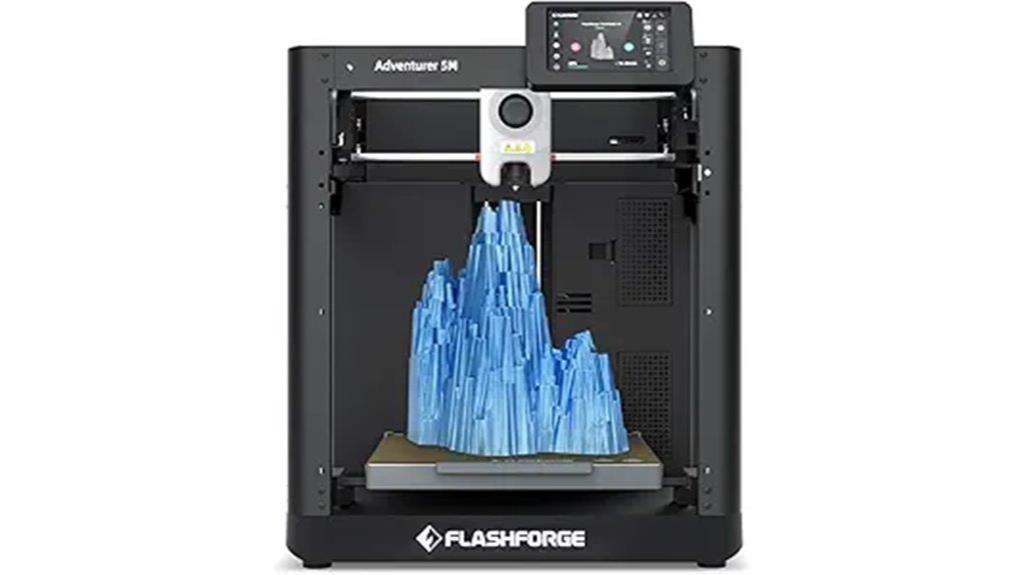

FLASHFORGE Adventurer 5M 3D Printer

The FLASHFORGE Adventurer 5M 3D Printer stands out for its high-speed performance and real-time remote monitoring capabilities, making it an ideal choice for manufacturers seeking efficient, reliable, and user-friendly heavy-duty 3D printing. Its Core XY structure enables speeds up to 600mm/s and 20,000mm/s² acceleration, while the optional 5M camera allows effortless remote tracking, parameter adjustments, and alerts. With full one-click auto leveling and quick setup, it’s perfect for beginners and educational use. Its advanced extruder heats to 280°C, supports various nozzle sizes, and includes features like filament detection and vibration compensation, ensuring consistent, high-quality prints.

Best For: manufacturers, educational institutions, and serious hobbyists seeking high-speed, reliable, and user-friendly 3D printing with remote monitoring capabilities.

Pros:

- High-speed performance with speeds up to 600mm/s and 20,000mm/s² acceleration, enabling quick production.

- Easy setup with full auto leveling and user-friendly design suitable for beginners.

- Advanced extruder supporting high temperatures up to 280°C and versatile nozzle options for diverse materials.

Cons:

- The open-source design may require DIY skills for customization and modifications.

- The optional 5M camera kit adds extra cost for remote monitoring features.

- The high-speed capabilities may demand more precise calibration to maintain print quality.

FLASHFORGE AD5M 3D Printer, CoreXY 600mm/s High-Speed, Auto Leveling, High-Temp Extruder, Quick-Swap Nozzle

For heavy-duty manufacturing environments that demand rapid turnaround times, the FLASHFORGE AD5M 3D Printer stands out with its blazing 600mm/s coreXY printing speed. Its high acceleration of 20,000mm/s² ensures quick, reliable prints perfect for prototyping and high-volume production. The auto bed leveling with a pressure sensor simplifies setup, while the high-temp extruder supports diverse materials up to 280°C. The quick-swap nozzles enable seamless switching between 0.25mm and 0.8mm sizes, balancing detail and speed. With remote control via the Flash Maker app and open-source customization, this printer offers precision, efficiency, and flexibility for heavy-duty manufacturing needs.

Best For: professionals and manufacturers needing ultra-fast, reliable 3D printing for prototyping, high-volume production, and complex material use.

Pros:

- Achieves top speeds up to 600mm/s with high acceleration for rapid printing.

- Supports diverse materials with a high-temp extruder up to 280°C and quick-swap nozzles.

- Features auto bed leveling, power loss recovery, and remote control for reliable, efficient operation.

Cons:

- May require a dedicated setup space due to its open design and high-speed operation.

- High-speed printing can sometimes compromise surface finish without proper calibration.

- Open-source hardware and firmware may need technical expertise for customization or troubleshooting.

Factors to Consider When Choosing Industrial FDM 3D Printers

When selecting an industrial FDM 3D printer, I focus on key factors like printing speed and power to meet production demands. Material compatibility, build size, and precision are essential for ensuring the printer fits my project’s requirements. Ease of operation also plays a big role in maintaining efficiency and minimizing downtime.

Printing Speed & Power

Choosing an industrial FDM 3D printer hinges considerably on its printing speed and power capabilities, as these factors directly impact production efficiency and quality. High printing speeds, like 600mm/s, allow for rapid production of large or multiple parts, cutting down overall manufacturing time. Increased acceleration rates, such as 20,000mm/s², help reduce vibrations during fast movements, resulting in better print quality. Reliable extruders and hotends that maintain consistent flow at high speeds ensure strong layer adhesion and smooth surfaces. Adequate power supplies are essential to support continuous high-speed operation without overheating or electrical issues. Additionally, advanced motion systems like CoreXY or delta architectures enable faster, more precise movements, maximizing throughput and maintaining accuracy in demanding industrial environments.

Material Compatibility Range

Selecting an industrial FDM 3D printer requires careful attention to its material compatibility range, which directly influences the variety of parts you can produce. Many printers support standard filaments like PLA, ABS, and PETG, but advanced models handle specialty materials such as polycarbonate, nylon, and carbon fiber composites. High-performance machines often feature hotends capable of reaching 300°C or more, allowing for high-temperature materials like PA12-CF or PET-CF. A heated build chamber at 65°C or higher improves adhesion and reduces warping, especially with ABS and ASA. Compatibility with flexible, high-strength, or chemically resistant filaments demands hardware like hardened steel hotends and precise temperature control. Ensuring the printer accommodates different filament diameters and types with adjustable extrusion systems enhances versatility for heavy-duty manufacturing needs.

Build Volume & Size

The build volume of an industrial FDM 3D printer determines the size and complexity of parts you can produce in a single print, which is essential for efficiency and project scope. Larger build areas, like 325×325×315mm or 300×300×400mm, let you print sizable or multiple components at once, reducing assembly needs. This capability is ideal for large-scale projects or when producing parts in a single piece. Conversely, smaller printers with build volumes around 225×225×280mm suit detailed small parts or setups with limited space. Your choice depends on your typical project dimensions and future scalability. Ensuring the build size aligns with your manufacturing demands helps optimize productivity and minimizes post-processing or splitting parts, streamlining your workflow.

Precision & Accuracy

When evaluating industrial FDM 3D printers, precision and accuracy stand out as key factors that can make or break your manufacturing outcomes. High-precision models often deliver layer resolutions of 0.1mm or better, ensuring detailed, accurate parts. Reliable auto-calibration features like automatic bed leveling and axis calibration are crucial for consistent results. Technologies such as input shaping and pressure advance help minimize vibrations and extrusion issues, further enhancing dimensional accuracy. A stable filament feed mechanism, like dual gear extruders, reduces slipping and guarantees precise filament delivery for fine details. Additionally, a rigid frame structure combined with stable linear motion components is essential to maintain positional accuracy during high-speed printing. These elements collectively ensure your parts meet tight tolerances and quality standards.

Ease of Operation

Ease of operation is a critical factor that can substantially impact your efficiency and productivity with industrial FDM 3D printers. A user-friendly machine features automated bed leveling, pre-installed firmware, and simple calibration steps, reducing setup time and minimizing errors. Intuitive interfaces, such as touch screens with guided prompts, make managing complex print jobs straightforward, even for less experienced operators. Simplified filament management systems, including auto-loading features and dry boxes, help maintain smooth material flow during extended or high-volume runs. Clear documentation, remote monitoring options, and minimal manual adjustments contribute to a seamless workflow. Additionally, robust support features like automatic error detection and troubleshooting assure quick issue resolution, keeping production consistent and minimizing costly downtime.

Maintenance & Support

Regular maintenance and reliable support are indispensable to keeping your industrial FDM 3D printers running smoothly and producing consistent quality. Routine tasks like nozzle cleaning, bed leveling, and firmware updates prevent issues and extend the printer’s lifespan. Having access to dependable support services, including technical assistance, replacement parts, and software updates, helps minimize downtime and keeps production on track. Many advanced printers now feature remote diagnostics and troubleshooting through network or cloud connectivity, enabling quicker problem resolution. Additionally, exhaustive warranties and service plans that cover hardware repairs and software upgrades are crucial for maintaining operational efficiency. Staying informed about firmware upgrades and hardware recalls ensures your equipment remains compatible with new materials and features, avoiding disruptions during long-term industrial use.

Cost & Budgeting

Choosing an industrial FDM 3D printer involves more than just comparing features; understanding the costs involved helps guarantee your investment aligns with your budget and project goals. These printers can range from several thousand to over fifty thousand dollars, depending on capabilities. Remember to account for additional expenses like maintenance, replacement parts, and specialized filaments, which can substantially impact the total cost. Higher-priced models often provide larger build volumes, faster speeds, and advanced features such as multi-material printing and automated calibration. It’s vital to consider the total cost of ownership, including software licenses, training, and operational expenses. Setting a clear budget helps identify feasible features and ensures you select a printer that meets your needs without exceeding your financial limits.

Frequently Asked Questions

What Maintenance Routines Are Essential for Heavy-Duty FDM Industrial Printers?

I prioritize regular cleaning of the print bed and extruder to prevent clogs and guarantee quality. I also check and tighten belts, replace worn nozzles, and lubricate moving parts monthly. Monitoring filament tension and ensuring cooling fans operate properly are key. Additionally, I run calibration routines weekly and update firmware to keep the machine running smoothly. Consistent maintenance helps me avoid costly downtime and keeps my heavy-duty printer performing at its best.

How Do Material Options Impact Industrial FDM Printer Durability?

Material options are like choosing armor for a knight; the right one boosts durability and performance. I’ve seen how using high-strength thermoplastics like ABS or reinforced composites can extend a printer’s lifespan and handle demanding jobs. The tougher the material, the more resilient the machine becomes against wear and tear. So, selecting the right filament isn’t just about quality—it’s about ensuring your printer stays reliable in heavy-duty production.

What Safety Features Are Standard in Heavy-Duty FDM 3D Printers?

Heavy-duty FDM 3D printers come with standard safety features like enclosure doors, emergency stop buttons, and thermal protection systems. I always look for models with enclosed chambers to contain fumes and prevent accidental contact with hot components. Automated shutoff functions are also essential for safety, especially during malfunctions. These features help me work confidently, knowing that safety is prioritized while handling high-power equipment.

How Do Print Speed and Precision Affect Manufacturing Efficiency?

I find that faster print speeds boost production capacity, but if precision drops, it can lead to faulty parts and delays. Conversely, high precision ensures quality but might slow down overall output. Striking a balance is key; optimized speeds with reliable accuracy maximize efficiency, reduce waste, and keep projects on schedule. Prioritizing both allows manufacturers to meet demand without sacrificing quality or speed.

What Are the Typical Operational Costs Associated With Industrial FDM Printers?

Did you know that operational costs for industrial FDM printers can range from $10 to $50 per hour? I’ve found that these costs include filament expenses, maintenance, and energy consumption. When I plan a project, I always factor in these variables to avoid surprises. Effective management of filament waste and regular maintenance can appreciably reduce overall expenses, helping me maximize efficiency and profitability in heavy-duty manufacturing.

Conclusion

When choosing an industrial FDM 3D printer, I look at factors like build volume, speed, and reliability. Did you know that the global industrial 3D printing market is expected to grow at a CAGR of over 23% through 2025? This shows how essential heavy-duty manufacturing is becoming. Investing in the right printer means staying ahead in this rapidly evolving industry, ensuring you meet demands efficiently and effectively.