If you’re looking for the 15 best reflow ovens for PCB assembly in 2026, I recommend exploring a variety of models from compact options like the T962 with infrared heating to larger, advanced units such as the T-962C or BGA rework stations like the IR6500. Features to contemplate include precise temperature control, support for different PCB sizes, and automation capabilities. Keep going to discover detailed insights and find the perfect fit for your needs.

Key Takeaways

- Top models feature precise temperature control, uniform heating, and multiple profiles for consistent PCB soldering results.

- Advanced units offer larger capacities, dual heating modes, and integrated safety features suitable for various PCB sizes.

- Industry-leading brands provide durable, easy-to-maintain reflow ovens with user-friendly interfaces and programmable profiles.

- Specialized options include BGA rework stations with multi-zone control and high thermal efficiency for complex assemblies.

- Selection depends on PCB size, component compatibility, heating method, and automation features to optimize assembly efficiency in 2026.

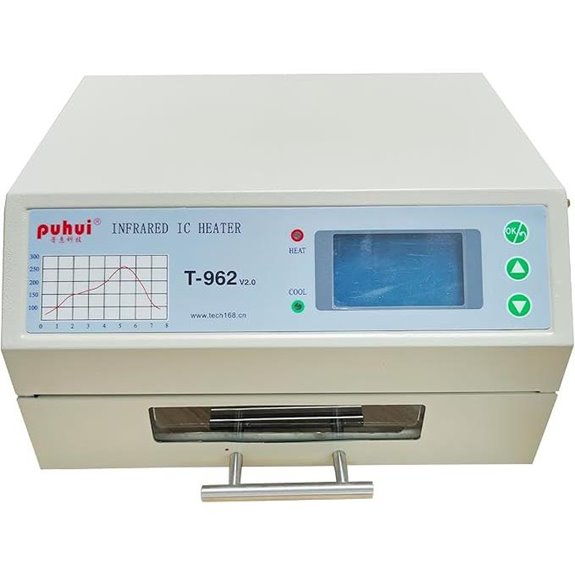

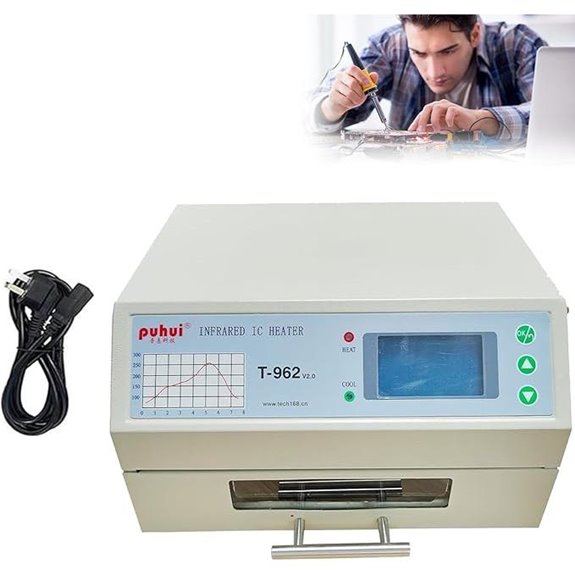

| T962 Reflow Oven with Infrared Heater 7.08×9.25in |  | Best Automation | Power: 800W | Soldering Area: 180×235mm | Temperature Range: 0°C–280°C | VIEW LATEST PRICE | See Our Full Breakdown |

| INTBUYING T962A Reflow Oven with Infrared Heater |  | Best Intelligent Control | Power: 1500W | Soldering Area: 300×320mm | Temperature Range: 0°C–280°C | VIEW LATEST PRICE | See Our Full Breakdown |

| 800W Infrared Reflow Oven with Hot Air Circulation |  | Most Reliable | Power: 800W | Soldering Area: 180×235mm | Temperature Range: 0°C–280°C | VIEW LATEST PRICE | See Our Full Breakdown |

| INTSUPERMAI Reflow Oven T-937 Micro-Computer Control |  | User-Friendly | Power: Not specified (implied 800W) | Soldering Area: Not specified | Temperature Range: 0°C–350°C | VIEW LATEST PRICE | See Our Full Breakdown |

| Infrared Reflow Oven Furnace for PCB Soldering |  | Versatile Performance | Power: 800W | Soldering Area: 180×235mm | Temperature Range: 0°C–280°C | VIEW LATEST PRICE | See Our Full Breakdown |

| SMT Reflow Oven T-962C Infrared Soldering Machine |  | Entry-Level Choice | Power: 2900W | Soldering Area: 600×400mm | Temperature Range: 100°C–350°C | VIEW LATEST PRICE | See Our Full Breakdown |

| 110V 800W Infrared Reflow Oven for PCB Soldering |  | High Precision | Power: 800W | Soldering Area: 300×320mm | Temperature Range: 100°C–350°C | VIEW LATEST PRICE | See Our Full Breakdown |

| Infrared Reflow Oven for BGA Rework and Soldering |  | Industrial Grade | Power: 800W | Soldering Area: 180×235mm | Temperature Range: 100°C–350°C | VIEW LATEST PRICE | See Our Full Breakdown |

| INTSUPERMAI T-937M Reflow Oven with Soldering Area |  | Robust Construction | Power: 800W | Soldering Area: 290×375mm | Temperature Range: Room temp–350°C | VIEW LATEST PRICE | See Our Full Breakdown |

| SMT T-962A Reflow Oven with Infrared Heating |  | Compact Powerhouse | Power: 1500W | Soldering Area: 300×320mm | Temperature Range: 0°C–280°C | VIEW LATEST PRICE | See Our Full Breakdown |

| Reflow Soldering Station T962 800W Infrared Oven |  | Large Soldering Area | Power: 800W | Soldering Area: 180×235mm | Temperature Range: 100°C–350°C | VIEW LATEST PRICE | See Our Full Breakdown |

| AE-6070 Precision Reflow Oven |  | Accurate Temperature | Power: 3600W | Soldering Area: 20×16 inches | Temperature Range: Not specified | VIEW LATEST PRICE | See Our Full Breakdown |

| ITECHSMT Reflow Oven Infrared & Hot Air 10″x8 |  | Small-Batch Friendly | Power: Not specified (designed for efficiency) | Soldering Area: 6-12 PCB boards | Temperature Range: Up to 572°F (~300°C) | VIEW LATEST PRICE | See Our Full Breakdown |

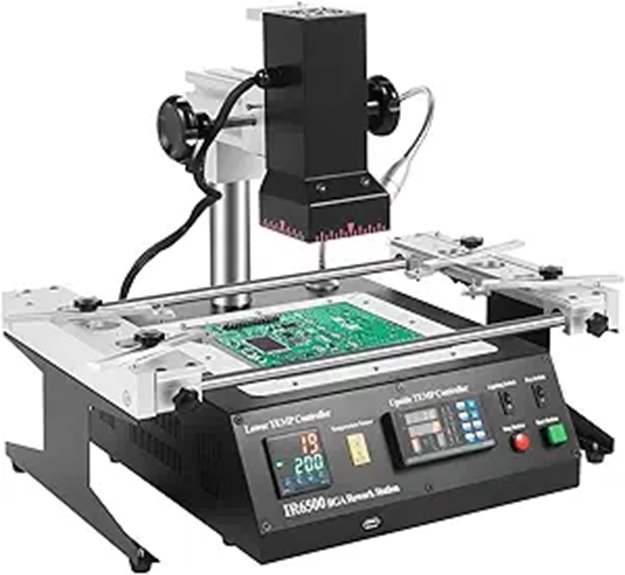

| IR6500 BGA Rework Station with Infrared Soldering |  | Professional Rework | Power: Not specified (designed for durability) | Soldering Area: Varies, supports PCB sizes | Temperature Range: Precise, multiple zones | VIEW LATEST PRICE | See Our Full Breakdown |

| INTSUPERMAI Reflow Soldering Station T937S Oven |  | Advanced Features | Power: 800W | Soldering Area: 290×375mm | Temperature Range: Room temp–300°C | VIEW LATEST PRICE | See Our Full Breakdown |

More Details on Our Top Picks

T962 Reflow Oven with Infrared Heater 7.08×9.25in

If you’re looking for a compact, reliable reflow oven suitable for small-scale PCB assembly or repair, the T962 with infrared heating is an excellent choice. It features full automation controlled by a microcomputer, simplifying operation from preheating to cooling. The oven supports eight memory waveforms for different reflow processes and combines functions like forced heating, drying, insulation, shaping, and rapid cooling. Its infrared hot air heating and uniform temperature fan deliver consistent, fast heating within a 0°C to 280°C range. With a 7.08×9.25-inch workspace, it accommodates various PCB sizes and packaging types, making it versatile for many applications.

- Power:800W

- Soldering Area:180×235mm

- Temperature Range:0°C–280°C

- Control Type:Microcomputer

- Automation Features:Fully automated, 8 profiles

- Additional Features:Infrared + fan, large area

- Additional Feature:Large welding area (180×235mm)

- Additional Feature:Supports multiple packaging types

- Additional Feature:User-friendly human-machine interface

INTBUYING T962A Reflow Oven with Infrared Heater

The INTBUYING T962A Reflow Oven with Infrared Heater stands out as an ideal choice for small-scale PCB assembly and R&D projects, thanks to its precise temperature control and versatile heating methods. It offers 1500 W power, a generous 11.8×12.6 inch soldering area, and a temperature range up to 280℃, with an upper limit of 350℃. The oven combines infrared radiation and circulating air heating for uniform results, featuring 8 preset temperature curves and a visual, microcomputer-controlled interface. Its compact, lightweight design makes it easy to transport and store, while the smoke exhaust interface guarantees safety and environmental compliance. Perfect for soldering SMDs, BGAs, and small PCBs.

- Power:1500W

- Soldering Area:300×320mm

- Temperature Range:0°C–280°C

- Control Type:Microcomputer

- Automation Features:Automatic control, 8 profiles

- Additional Features:Infrared + circulating air, smoke exhaust

- Additional Feature:Visual drawer-type workbench

- Additional Feature:Automatic control with smoke exhaust

- Additional Feature:Suitable for small batch production

800W Infrared Reflow Oven with Hot Air Circulation

For professionals seeking precise and uniform soldering, the W Infrared Reflow Oven with Hot Air Circulation stands out due to its advanced hot air circulation system. With 800W power and a spacious 180 x 235 mm area, it handles various PCB encapsulations efficiently. Fully microcomputer-controlled, it manages the entire soldering cycle—preheating, reflow, and cooling—with up to 8 stored temperature profiles. The oven offers adjustable temperatures up to 280℃ and cycle times from 1 to 8 minutes. Its forced hot air circulation guarantees even heating, making it ideal for reflow soldering, drying, insulation, and component rework.

- Power:800W

- Soldering Area:180×235mm

- Temperature Range:0°C–280°C

- Control Type:Microcomputer

- Automation Features:Fully microcomputer-controlled, 8 profiles

- Additional Features:Infrared + hot air circulation

- Additional Feature:Hot air circulation system

- Additional Feature:Upgraded version 2.0 (computer connect)

- Additional Feature:Supports various PCB encapsulation forms

INTSUPERMAI Reflow Oven T-937 Micro-Computer Control

With its microcomputer control system, the INTSUPERMAI T-937 Reflow Oven stands out as an excellent choice for professionals seeking precision and automation in PCB assembly. It stores and executes eight different soldering profiles, ensuring consistent results. The oven supports temperature correction and compensation for accurate control, with eight pre-programmed curves and self-setting options. Operating from room temperature up to 350℃, it offers cycle times from 2 to 16 minutes, along with dedicated heating and forced cooling functions. Its design includes a visible window, intuitive LCD, and durable stainless steel construction, making it user-friendly and reliable for various PCB processes.

- Power:Not specified (implied 800W)

- Soldering Area:Not specified

- Temperature Range:0°C–350°C

- Control Type:Microcomputer

- Automation Features:Automated, 8 profiles, self-setting

- Additional Features:Infrared + forced cooling, drawer design

- Additional Feature:Built-in smoke exhaust port

- Additional Feature:Stainless steel construction

- Additional Feature:Visible process monitoring window

Infrared Reflow Oven Furnace for PCB Soldering

An infrared reflow oven furnace like the T962 stands out for those seeking precise temperature control and efficient rework capabilities. Its microcomputer-controlled system ensures even heat distribution, vital for handling leaded, lead-free SMD, and BGA components. The LCD display provides clear process visibility, making adjustments straightforward. With storage for eight profiles, switching between settings is quick, boosting productivity. The T962’s versatile design handles double-sided PCBAs and intricate parts like QFPs and CHIPs, suitable for small-scale rework or large productions. Its robust construction guarantees long-lasting reliability, while infrared heating combined with hot air circulation delivers consistent, accurate results every time.

- Power:800W

- Soldering Area:180×235mm

- Temperature Range:0°C–280°C

- Control Type:Microcomputer

- Automation Features:Microcomputer control, 8 profiles

- Additional Features:Infrared + hot air, visible chamber

- Additional Feature:8 stored temperature profiles

- Additional Feature:Hot air circulation technology

- Additional Feature:Durable high-quality components

SMT Reflow Oven T-962C Infrared Soldering Machine

The SMT Reflow Oven T-962C Infrared Soldering Machine stands out as a top choice for small-scale PCB assembly and prototyping, thanks to its large 15.7 x 23.6-inch working area and microcomputer-controlled operation. It’s ideal for automatic reflow soldering, fixing bad joints, replacing defective components, and handling small prototypes. With preset intelligent temperature curves and real-time monitoring, it simplifies complex soldering tasks, ensuring precision. Its design supports high efficiency, featuring dual vent pipe interfaces for smoke management. Overall, the T-962C offers reliable, user-friendly performance tailored for small production runs, repair work, and detailed prototype development.

- Power:2900W

- Soldering Area:600×400mm

- Temperature Range:100°C–350°C

- Control Type:Microcomputer

- Automation Features:Automated, multiple profiles

- Additional Features:Infrared + hot air, large working area

- Additional Feature:600 x 400 mm area

- Additional Feature:Pre-installed vent pipe interfaces

- Additional Feature:Supports small-scale prototypes

110V 800W Infrared Reflow Oven for PCB Soldering

If you’re seeking a reliable reflow oven that combines precise temperature control with ease of use, the V 800W Infrared Reflow Oven is an excellent choice. It features advanced infrared heating technology that ensures even, consistent heat distribution, essential for high-quality solder joints. Its user-friendly interface makes it suitable for both beginners and professionals. Compact and lightweight, it fits easily on workbenches or desktops, saving space. Built with durable materials, it guarantees long-term performance for various applications like circuit board repair, electronics assembly, and BGA reflow. Overall, it’s a dependable tool for achieving professional soldering results efficiently.

- Power:800W

- Soldering Area:300×320mm

- Temperature Range:100°C–350°C

- Control Type:Microcomputer

- Automation Features:Automated, multiple profiles

- Additional Features:Infrared + hot air, large area

- Additional Feature:Compact space-saving design

- Additional Feature:Supports PCB repair and assembly

- Additional Feature:Rated for long-term use

Infrared Reflow Oven for BGA Rework and Soldering

For professionals seeking precise BGA rework and soldering, infrared reflow ovens like the T962 stand out due to their automatic infrared heating and advanced temperature control. With 800W power and a soldering area of 180 x 235 mm, it handles single and double PCB panels efficiently. The microcomputer control manages the entire process, including preheating, soaking, reflux, and cooling, ensuring consistent quality. Eight pre-set temperature waveforms allow customization for different tasks. Its move heating and cool-off functions enhance process control and safety, making it ideal for delicate BGA rework and high-precision soldering applications.

- Power:800W

- Soldering Area:180×235mm

- Temperature Range:100°C–350°C

- Control Type:Microcomputer

- Automation Features:Automated, multiple profiles

- Additional Features:Infrared + hot air, precise control

- Additional Feature:Move heating & cool-off functions

- Additional Feature:Precise temperature zones

- Additional Feature:Suitable for professional rework

INTSUPERMAI T-937M Reflow Oven with Soldering Area

Designed for small-scale and R&D PCB assembly, the INTSUPERMAI T-937M Reflow Oven stands out with its precise temperature control and versatile heating modes. It features a spacious soldering area of up to 14.76 inches in width, supporting both lead-free and lead-based soldering. The oven uses infrared and hot air heating for even heat distribution, with PID control ensuring consistent results. Equipped with multiple temperature curves, manual heating, and forced cooling, it adapts to various manufacturing needs. Its safety features include an exhaust system and solid-state relay, making it reliable for delicate PCB work, whether for reflow, drying, or curing processes.

- Power:800W

- Soldering Area:290×375mm

- Temperature Range:Room temp–350°C

- Control Type:Microcomputer

- Automation Features:Programmable profiles, auto cycles

- Additional Features:Infrared + hot air, multiple zones

- Additional Feature:Multiple temperature curves

- Additional Feature:Non-contact solid-state relay

- Additional Feature:Wide application for PCB maintenance

SMT T-962A Reflow Oven with Infrared Heating

The SMT T-962A Reflow Oven with Infrared Heating stands out for its precise temperature control and user-friendly operation, making it an excellent choice for small-scale electronics workshops and prototype developers. It features an 11.8 x 12.6-inch soldering area, perfect for various assembly tasks. The microcomputer control system offers eight preset intelligent temperature curves with real-time monitoring, simplifying operation. Designed for reflow soldering of SMD and BGA components, it effectively repairs solder joints and replaces defective parts. With high efficiency, a large working area, and built-in vent pipe interfaces, the T-962A combines performance and ease of use for small production runs and prototypes.

- Power:1500W

- Soldering Area:300×320mm

- Temperature Range:0°C–280°C

- Control Type:Microcomputer

- Automation Features:Automatic, 8 profiles

- Additional Features:Infrared + hot air, smoke exhaust ports

- Additional Feature:2 pre-installed vent interfaces

- Additional Feature:Suitable for small prototypes

- Additional Feature:Real-time operation monitoring

Reflow Soldering Station T962 800W Infrared Oven

If you’re seeking a versatile reflow oven capable of handling small batch production or research projects, the Reflow Soldering Station T962 800W Infrared Oven stands out. It offers powerful 800W infrared heating with a spacious 180 x 235 mm area, supporting various PCB types like CHIP, SOP, and BGA. Its microcomputer control manages all phases—from preheating to cooling—while temperature adjustments range from 100℃ to 350℃. The oven features memory for up to eight profiles, ensuring consistency. With built-in drying, insulation, reshaping, and rapid cooling functions, it’s ideal for BGA rework, repairs, and small-scale assembly tasks in research or enterprise settings.

- Power:800W

- Soldering Area:180×235mm

- Temperature Range:100°C–350°C

- Control Type:Microcomputer

- Automation Features:Microcomputer control, profiles

- Additional Features:Infrared + fan, large heating area

- Additional Feature:Spacious 180×235mm area

- Additional Feature:Fast infrared heating

- Additional Feature:Multiple functions (drying, shaping)

AE-6070 Precision Reflow Oven

For professionals seeking precise temperature control in PCB assembly, the AE-6070 Precision Reflow Oven stands out with its advanced thermal management system. It features high-efficient far-infrared heating elements and thermal coupler sensors that deliver accurate temperature measurements. Managed by a core microprocessor, it precisely adjusts the heating curve and distribution, ensuring consistent results. With a maximum power of 3600 W and a working area of 20 by 16 inches, it handles sizable batches efficiently. Its ability to finely tune the temperature curve makes it ideal for sensitive components, providing reliable, repeatable reflow cycles for high-quality assembly.

- Power:3600W

- Soldering Area:20×16 inches

- Temperature Range:Not specified

- Control Type:Microprocessor

- Automation Features:Fully automated, precise curves

- Additional Features:Infrared + precise sensors

- Additional Feature:High-efficient far-infrared elements

- Additional Feature:Microprocessor-controlled heating

- Additional Feature:20×16 inch working area

ITECHSMT Reflow Oven Infrared & Hot Air 10″x8

Designed with compactness in mind, the ITECHSMT Reflow Oven Infrared & Hot Air 10″×8″ is ideal for small laboratories and batch production setups. Its drawer design saves 65% floor space and processes 6-12 PCBs simultaneously without line modifications, enabling quick batch changes. Equipped with precise temperature control via an intelligent PID algorithm, it maintains uniformity within ±35.6℉ and reaches working temperature in just 5 minutes. Dual-mode heating ensures even heat distribution, preventing defects. Easy-to-use LCD interface with preset profiles and online connectivity make operation straightforward, while modular design simplifies maintenance, reducing downtime and costs—perfect for small-scale, high-quality PCB assembly.

- Power:Not specified (designed for efficiency)

- Soldering Area:6-12 PCB boards

- Temperature Range:Up to 572°F (~300°C)

- Control Type:PID, microcontroller

- Automation Features:Programmable, multiple profiles

- Additional Features:Infrared + rapid heating

- Additional Feature:Modular detachable heating modules

- Additional Feature:Supports industry-standard profiles

- Additional Feature:Fault self-diagnosis system

IR6500 BGA Rework Station with Infrared Soldering

The IR6500 BGA Rework Station with Infrared Soldering stands out for its precise temperature control, making it an ideal choice for professionals who demand accuracy during complex PCB rework tasks. It features 8 temperature segments, 8 thermostatic zones, and 10 programmable profiles, ensuring detailed regulation. Built from durable aluminum alloy and iron with oxidation and spray coatings, it’s designed for long-term reliability. The integrated workbench keeps cables tidy and provides secure PCB fixation with adjustable guides. Plus, it connects easily to a computer via USB, allowing for fine-tuned control through proprietary software. This station handles CPU sockets, shields, and lead-free solder with ease.

- Power:Not specified (designed for durability)

- Soldering Area:Varies, supports PCB sizes

- Temperature Range:Precise, multiple zones

- Control Type:Microcomputer

- Automation Features:Fully automatic, customizable profiles

- Additional Features:Infrared + integrated workbench

- Additional Feature:Adjustable linear PCB bracket

- Additional Feature:USB connection for software control

- Additional Feature:Wear-resistant, durable build

INTSUPERMAI Reflow Soldering Station T937S Oven

If you’re looking for a reliable reflow oven that guarantees precise and consistent soldering, the INTSUPERMAI Reflow Soldering Station T937S stands out with its advanced microcomputer control system. It allows seamless automation, storing and executing up to 8 soldering profiles for ideal results. The oven supports a wide temperature range up to 300°C, with adjustable cycle times from 2 to 16 minutes, and uses infrared and hot air heating for versatile processing. Its design includes a drawer with a clear window, touchscreen controls, and a smoke exhaust system, making it user-friendly and efficient for small-batch or single-run PCB assembly tasks.

- Power:800W

- Soldering Area:290×375mm

- Temperature Range:Room temp–300°C

- Control Type:Microcomputer

- Automation Features:Automated, multiple profiles

- Additional Features:Infrared + hot air, efficient heating

- Additional Feature:Built-in smoke exhaust system

- Additional Feature:Intelligent touchscreen interface

- Additional Feature:Supports high-standard soldering tasks

Factors to Consider When Choosing Reflow Ovens for PCB Assembly

When selecting a reflow oven, I look at key factors like heating method options, size, and capacity to match my production needs. I also consider temperature precision, automation features, and safety measures to guarantee efficient and safe operation. These points help me choose the best oven for reliable, high-quality PCB assembly.

Heating Method Options

Choosing the right heating method for a reflow oven is essential because it directly affects soldering quality, process efficiency, and energy use. Infrared heating delivers direct, rapid heat transfer to components, which reduces cycle times and boosts efficiency. It’s ideal for quick, targeted heating. Hot air circulation, on the other hand, ensures even heat distribution across the entire PCB by forcing warm air over all surfaces, minimizing hot spots and promoting uniform solder joints. Some ovens combine both methods—dual-mode heating—to optimize temperature control and process stability. The choice depends on your specific needs: infrared is great for quick, localized heating, while hot air suits larger or more complex assemblies requiring uniformity. Your selection impacts solder quality, energy consumption, and overall production reliability.

Size and Capacity

Selecting the right size and capacity for your reflow oven is vital to matching your PCB production needs. The oven’s dimensions should align with your PCB sizes, typically ranging from 150x180mm to 600x400mm. Larger capacity ovens can handle bigger boards or multiple PCBs at once, boosting throughput for high-volume runs. Conversely, small-scale or prototype work benefits from compact ovens with limited working areas, usually under 200x235mm. It’s essential to evaluate whether the oven’s maximum PCB width and length accommodate your largest boards to avoid process limitations. Also, consider how many PCBs you process per cycle; a higher capacity oven can markedly improve efficiency in busy production lines. Matching capacity to your workflow ensures peak performance and scalability.

Temperature Precision Level

Achieving consistent solder joints depends heavily on the reflow oven’s temperature precision. I look for ovens that keep temperature fluctuations within ±2°C, as this level of control guarantees reliable, high-quality results. Precise temperature management reduces the risk of cold solder joints and prevents thermal damage to sensitive components. Advanced models offer programmable profiles with multiple segments, allowing me to tailor the heat cycle to specific PCB requirements. Uniform heat distribution across the entire board is essential for even soldering, so I prioritize ovens with excellent heat circulation. Accurate temperature sensors, like thermocouples, are vital for real-time feedback and maintaining stable thermal conditions. In short, a high level of temperature precision directly impacts the quality and consistency of the final assembly.

Automation Capabilities

Automation capabilities in reflow ovens play a critical role in ensuring consistent and efficient PCB assembly. Programmable temperature profiles allow me to maintain uniform soldering quality across multiple runs, saving time and reducing errors. Many models include memory functions that store up to eight different heating waveforms, enabling quick setup and process repeatability. Microcomputer control systems manage preheating, soaking, reflow, and cooling stages automatically, minimizing manual intervention and increasing efficiency. Advanced ovens offer real-time process monitoring and adjustments, helping me catch issues early and improve yield. Integration with computer control systems further enhances automation by allowing customized process curves and data logging. Overall, these features streamline production, improve quality, and reduce the risk of defects, making automation capabilities a critical factor in choosing the right reflow oven.

Safety Features Included

Safety features are a crucial aspect to contemplate when choosing a reflow oven for PCB assembly because they directly impact operator safety and equipment reliability. Reliable safety grounding and circuit protection prevent electrical hazards, giving peace of mind during operation. Smoke exhaust systems or ports are essential for managing fumes, reducing inhalation risks from solder vapors. Automatic shut-off and cooling functions help prevent overheating, protecting both components and operators from thermal damage. Temperature monitoring sensors and alarms provide real-time alerts for abnormal fluctuations, ensuring process safety and equipment integrity. User-friendly interfaces with emergency stop buttons and clear safety indicators enable quick responses to potential hazards. Prioritizing these safety features helps create a safer workspace and minimizes downtime caused by accidents or equipment failures.

Compatibility With Components

When selecting a reflow oven for PCB assembly, it’s important to guarantee it can handle the specific components you’ll be working with. Make sure the oven supports the package types you use, like CHIP, SOP, QFP, or BGA, to ensure proper soldering. Check that its temperature range and control precision match the thermal requirements of your components and solder materials. The heating technology—infrared, hot air, or a combination—should provide uniform heat distribution suited to your assembly needs. Also, confirm compatibility with multi-layer PCBs and that the maximum component height won’t cause damage during reflow. Finally, consider if the oven’s cycle times and temperature profiles can be customized to match your specific reflow profiles, guaranteeing optimal results for each project.

Frequently Asked Questions

What Is the Typical Lifespan of a Reflow Oven?

A typical reflow oven lasts around 8 to 15 years, depending on usage and maintenance. I’ve found that regular cleaning, calibrations, and replacing worn parts can extend its lifespan considerably. If you keep up with proper care, your oven can serve you well for many years. Of course, high-quality models tend to last longer, so investing in a reliable brand pays off over time.

How Energy-Efficient Are Different Reflow Oven Models?

They say, “You get what you pay for,” and that’s true for reflow ovens’ energy efficiency. I’ve found that newer models with advanced insulation and precise temperature controls use notably less energy, saving money in the long run. While some high-end ovens might cost more upfront, their energy savings often outweigh initial costs. So, it’s smart to compare models’ energy ratings before making a choice.

Can Reflow Ovens Handle Different PCB Sizes Easily?

Yes, reflow ovens can handle different PCB sizes easily. I find that most models come with adjustable conveyor widths and customizable thermal profiles, making it simple to accommodate various board dimensions. Whether you’re working with small prototypes or large production runs, these ovens adapt quickly. Just make certain you select a model with versatile conveyor options and adjustable settings to smoothly process different PCB sizes without hassle.

What Maintenance Is Required for Optimal Reflow Oven Performance?

I keep my reflow oven in top shape by performing daily cleaning and regularly inspecting the conveyor belt and heating elements. I calibrate the temperature sensors monthly to avoid costly mistakes. Replacing worn-out parts promptly and updating software when needed guarantees my oven runs smoothly. Skipping maintenance is like ignoring warning signs on a dashboard—eventually, it’ll cost you everything. Proper care keeps my PCB assembly flawless and efficient.

Are There Safety Features Specific to Infrared Reflow Ovens?

Infrared reflow ovens often come with safety features like automatic shutoff, temperature sensors, and protective covers to prevent burns or accidents. I always check for these before purchasing, as they guarantee safe operation in busy work environments. These features not only keep users safe but also protect the equipment from overheating or damage. When selecting an oven, prioritize models with reliable safety measures to ensure peace of mind during use.

Conclusion

Choosing the right reflow oven is like finding the perfect dance partner—trustworthy, precise, and in sync with your needs. I remember struggling with inconsistent solder joints until I found a model that matched my workflow perfectly. With options like infrared heaters and micro-computer controls, you can turn your PCB assembly into a smooth, flawless performance. Just like a well-choreographed dance, the right oven makes all the difference in your production quality.